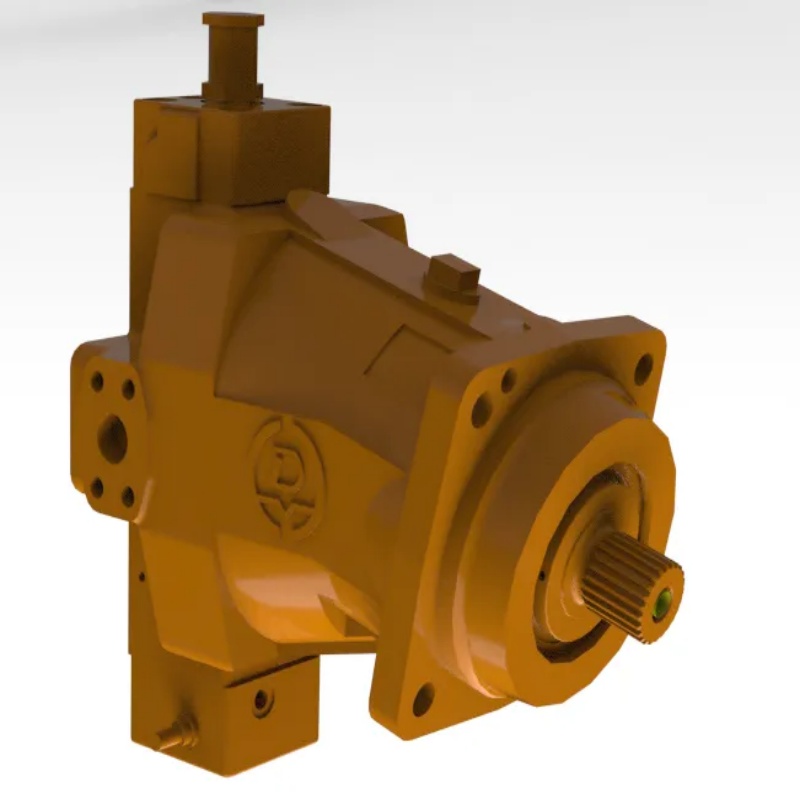

When working with hydraulic systems, choosing the right directional control valve can make or break your operation. The Directional Control Valve WMM 10 from Bosch Rexroth has become a popular choice in industrial settings, and for good reason. This manually operated valve handles high pressure and high flow rates while maintaining reliability that's hard to match.

What Makes the WMM 10 Stand Out

The Directional Control Valve WMM 10 is designed for manual control of hydraulic fluid in industrial machinery. What sets it apart is its ability to handle pressure up to 315 bar at ports P, A, and B, with flow rates reaching 160 liters per minute. These numbers matter because they allow the valve to control large hydraulic actuators without compromising on response time or precision.

The valve uses a simple but effective design. When you move the manual handle, it shifts an internal spool that redirects hydraulic fluid flow. This direct mechanical connection gives operators immediate feedback and control, which is especially valuable during machine setup or emergency situations. The switching time typically falls between 10 and 45 milliseconds, depending on oil viscosity and how much force you apply to the handle.

Understanding the Technical Specifications

The Directional Control Valve WMM 10 follows the NG10 sizing standard, also known as D05 or CETOP 5. This standardization means the valve can replace other NG10 valves without modifying your mounting plate. The valve weighs between 3.3 and 4.4 kilograms and can be installed in any position, giving you flexibility in system design.

One detail that often gets overlooked is the return port pressure limit. While the working ports can handle 315 bar, the T port (return line) maxes out at 160 bar. This difference matters when you're designing your hydraulic circuit. High pressure spikes in the return line can cause the spool to stick or move unexpectedly, which is why many engineers design dedicated low-pressure return lines for systems using the Directional Control Valve WMM 10.

The operating force needed to switch the valve depends on the configuration. Spring-return models need 18 to 20 Newtons of force, while detent versions (marked with "F" in the model code) require 30 to 40 Newtons. The detent feature locks the spool in position, which is useful when you need to maintain a valve setting without holding the handle.

How to Read the Model Code

Understanding the model code helps you order the right valve. A typical code like 4WMM10E5X/F breaks down into specific components. The "4" indicates four ports, "WMM" shows it's a manually operated lever valve, "10" refers to the NG10 size, "E" describes the spool configuration (in this case, all ports blocked in neutral), "5X" identifies the component series, and "F" means it has a detent mechanism.

The spool symbol makes a real difference in how your system behaves. An "E" spool blocks all ports in the neutral position, which prevents drift in your actuators. A "W" spool connects all ports to tank in neutral, which unloads the pump and reduces heat buildup. A "J" spool creates a series circuit that's good for low-speed operation. Choosing the wrong spool type can lead to performance issues, so it's worth taking time to understand your system needs.

Hydraulic Fluid Compatibility

The Directional Control Valve WMM 10 works with various hydraulic fluids, but each type has specific requirements. Standard mineral oils like HL or HLP work with either NBR or FKM seals and operate normally across the full pressure range. Biodegradable options like HETG fluids also use NBR or FKM seals, while HEES fluids specifically need FKM seals.

Water-containing fire-resistant fluids (HFC) present special challenges. When using HFC fluids with the Directional Control Valve WMM 10, you need to limit the pressure differential to 50 bar instead of the normal 315 bar. The valve's expected lifespan also drops by 50 to 100 percent with HFC fluids. You also need to preload the return port to about 20 percent of the working pressure differential to prevent cavitation. These extra requirements increase your total cost of ownership, so factor that into your decision if you're considering HFC fluids.

Operating temperature ranges vary by seal material. NBR seals work from negative 30 to positive 80 degrees Celsius for the fluid itself, while ambient temperature should stay between negative 20 and positive 70 degrees Celsius. FKM seals offer slightly different ranges, running from negative 20 to positive 80 degrees Celsius for fluid temperature.

Keeping Your System Clean

Oil cleanliness makes a huge difference in valve performance. The Directional Control Valve WMM 10 requires fluid cleanliness of ISO 4406 Class 20/18/15 or better. This might seem like technical overkill, but contamination is the leading cause of spool sticking in manually operated valves. Even small particles can wedge between the spool and bore, causing the valve to hang up or move sluggishly.

Installing a high-quality filtration system pays off in the long run. The valve's mean time to dangerous failure (MTTFd) reaches 150 years under clean conditions, which shows that the valve itself is extremely reliable. Most failures trace back to external factors like contaminated oil, improper installation, or operating outside the specified pressure range.

Common Issues and Solutions

Spool sticking ranks as the most frequent problem with the Directional Control Valve WMM 10. This usually happens when particles accumulate around the spool or when operating in cold temperatures with high-viscosity oil. The solution involves maintaining proper oil cleanliness and ensuring your hydraulic fluid viscosity stays within the 2.8 to 500 square millimeters per second range.

Unexpected spool movement in detent versions can occur when pressure spikes in the return line overcome the 30 to 40 Newton holding force. This creates a safety risk because the valve might shift position without operator input. Adding a check valve in the return line or designing a separate low-pressure return circuit solves this problem.

Seal leakage develops over time as seals wear from normal operation. Regular inspection catches this early, before small leaks become major problems. When replacing seals, make sure you match the seal material to your hydraulic fluid type.

Pricing and Alternatives

The Directional Control Valve WMM 10 from Bosch Rexroth typically costs between $1,091 and $1,114 USD for OEM parts. This price reflects the engineering quality and certification that comes with the Rexroth brand. Lower-cost alternatives from manufacturers like Huade range from $38 to $132 USD and claim NG10 compatibility, but these come with risks.

Chinese manufacturers produce functionally similar valves at much lower prices. Huade offers a WMM 10 equivalent that matches the basic specifications of 315 bar pressure and 160 liters per minute flow. The question becomes whether the cost savings justify the potential risks in precision, documentation quality, and long-term support.

When comparing alternatives, pay close attention to actual specifications rather than just the model number. Some NG6 valves use similar naming conventions but only handle 80 liters per minute, which would bottleneck your system. Verify that any alternative truly provides the 160 liters per minute capacity that makes the Directional Control Valve WMM 10 suitable for larger actuators.

Installation Best Practices

Proper installation of the Directional Control Valve WMM 10 starts with the mounting surface. The valve mounts to a subplate that conforms to DIN 24340 A or ISO 4401-05-04-0-05 standards. Torque the mounting bolts to specification and use the correct seals between the valve and subplate. Even small installation mistakes can lead to internal leakage or reduced performance.

Pipe sizing matters more than many people realize. When flow rates approach 160 liters per minute, undersized piping creates excessive pressure drops and heat buildup. The return line especially needs adequate sizing because of the lower pressure rating on the T port.

For systems with high transient flow rates, installing a throttle cartridge in the P channel prevents shock waves and cavitation. A B08 cartridge with a 0.8 millimeter orifice provides a good starting point, though your specific application might need adjustment. This small addition protects valve life significantly in systems with sudden load changes.

Maintenance Strategy

A proactive maintenance approach maximizes the 150-year potential lifespan of the Directional Control Valve WMM 10. Regular oil analysis catches contamination problems before they damage the valve. Testing should include particle count, viscosity, and moisture content at minimum.

Filter replacement intervals depend on your operating environment and contamination rate. High-dust environments might need monthly filter changes, while clean industrial settings could go several months. Don't wait for differential pressure alarms to trigger before changing filters, as some damage may already have occurred.

Seal replacement follows a predictable schedule based on operating hours and pressure cycles. Keeping spare seal kits on hand reduces downtime when replacement becomes necessary. Document your maintenance activities to establish patterns that help predict future needs.

When to Choose the WMM 10

The Directional Control Valve WMM 10 excels in applications where manual control provides advantages over electrical actuation. Machine setup procedures often benefit from the direct feel and immediate response of manual valves. Emergency override systems also favor manual valves because they work even during electrical failures.

Large construction equipment, machine tools, and presses represent typical applications for the WMM 10. The combination of high pressure capacity and high flow rate handles the demands of large hydraulic cylinders and motors. The detent option works well for positioning applications where you need to lock a setting while attending to other tasks.

However, the valve isn't ideal for every situation. Automated systems that need remote control should use electrically actuated valves instead. Applications requiring precise flow control beyond simple on-off switching might need proportional valves. Understanding these limitations helps you choose the right valve for your specific needs.

Final Considerations

The Directional Control Valve WMM 10 represents mature hydraulic technology that delivers reliable performance when properly applied. Its 315 bar pressure rating and 160 liter per minute flow capacity place it among the more capable manual valves in the NG10 size class. The 150-year MTTFd figure reflects solid engineering, though achieving this requires attention to system cleanliness and proper maintenance.

When designing a new system or replacing an existing valve, focus on matching the valve capabilities to your actual requirements. Don't assume that higher specifications always mean better performance. A properly sized and maintained Directional Control Valve WMM 10 will outlast most of the machinery it controls.

The decision between OEM and alternative suppliers ultimately depends on your risk tolerance and total cost calculation. Initial price differences look attractive, but factor in the value of technical support, documentation quality, and warranty coverage. For critical applications where downtime carries high costs, the OEM option usually makes financial sense despite the higher upfront price.

Understanding the technical details of the Directional Control Valve WMM 10 helps you make informed decisions about specification, installation, and maintenance. This knowledge translates directly into better system performance and longer component life, which ultimately improves your bottom line.