When working with hydraulic systems, controlling flow direction is essential for safety and efficiency. The Bosch Rexroth M-SR cartridge valve serves as a reliable check valve that allows fluid to flow in one direction while completely blocking reverse flow. This component has become a standard choice in industrial hydraulic applications due to its compact design and leak-free performance.

What Is the M-SR Cartridge Valve

The M-SR cartridge valve is a screw-in type hydraulic check valve manufactured by Bosch Rexroth, one of the leading companies in hydraulic technology. This cartridge valve M-SR belongs to the 1X series and uses a poppet design to control fluid flow. The valve fits directly into a manifold block, which saves space compared to traditional line-mounted valves.

The basic operation is straightforward. When hydraulic fluid pushes against the valve in the forward direction with enough pressure, the poppet opens and allows flow. When pressure comes from the reverse direction, the poppet seals tightly against its seat, preventing any backflow. This metal-to-metal sealing creates a leak-tight closure that maintains system pressure without degradation over time.

The cartridge valve M-SR comes in two installation types: the KE angle valve for 90-degree flow paths and the KD inline valve for straight flow paths. This flexibility helps engineers design compact hydraulic circuits that fit within limited space.

Technical Specifications and Size Range

The M-SR cartridge valve is available in seven nominal sizes, designated as NG 6 through NG 30. Each size handles different flow rates and pressure levels depending on the application requirements.

For smaller systems, the NG 6 cartridge valve M-SR handles flows up to 6 liters per minute and operates at pressures up to 420 bar. As the size increases, the flow capacity grows significantly. The NG 10 version manages 50 liters per minute, while the NG 15 can handle 120 liters per minute. The largest standard size, NG 30, accommodates flows up to 400 liters per minute, though its maximum pressure rating drops to 250 bar.

The cracking pressure, which is the minimum pressure needed to open the valve, ranges from essentially zero (for springless versions) up to 5 bar. Most applications use the standard 0.5 bar spring, which provides reliable sealing while opening easily when forward flow begins. Higher cracking pressures like 1.5 bar or 3 bar are available for systems that need stronger reverse sealing force.

Operating temperature range depends on the seal material. Standard NBR seals work from negative 30 degrees Celsius to positive 80 degrees Celsius. For high-temperature or chemical-resistant applications, FKM seals extend the upper limit while narrowing the cold temperature range slightly.

The cartridge valve M-SR works with various hydraulic fluids including mineral oils, biodegradable fluids, and fire-resistant options. When using water-based fluids, the operating temperature should stay below 60 degrees Celsius to maintain seal longevity.

Installation Requirements and Mounting Details

Installing the M-SR cartridge valve requires attention to several dimensional and surface specifications. The valve body length varies by size, ranging from 33.3 millimeters for NG 6 up to 83.3 millimeters for NG 30, with a negative tolerance of 0.1 millimeters. The installation cavity follows the ZN 10001 standard, which ensures compatibility with properly designed manifold blocks.

Each size requires a specific threaded plug to seal the cavity. For example, the NG 10 cartridge valve M-SR uses part number R913011603, which has an 18 millimeter diameter bore and G 1/2 pipe thread. The NG 20 version uses a larger plug with a 30 millimeter bore and G 1 thread. These plugs must be lightly oiled before installation to prevent galling and ensure proper sealing.

Surface finish matters for reliable operation. The sealing surfaces should have a roughness value between Rz 8 and Rz 16. The valve can mount in any orientation, though avoiding air pockets in the circuit helps prevent cavitation and noise.

For high-pressure applications above 350 bar, applying Loctite 243 thread locker to the plug threads adds security against loosening from vibration. The cartridge valve M-SR maintains its rated pressure capacity when installed correctly with proper torque values.

Performance Characteristics and Flow Curves

Understanding how the M-SR cartridge valve behaves under different conditions helps engineers select the right size and spring. The relationship between flow rate and pressure drop follows a nonlinear curve that varies by valve size and cracking pressure setting.

Taking the NG 15 cartridge valve M-SR as an example, when flowing 100 liters per minute with a 0.5 bar spring, the pressure drop across the valve measures approximately 0.8 bar. As flow increases, the pressure drop rises more quickly due to the increased velocity through the valve opening. At 120 liters per minute, the pressure drop reaches roughly 1.2 bar.

For larger valves like the NG 30, the pressure drop remains lower at equivalent flow rates due to the larger flow area. At 400 liters per minute, the NG 30 cartridge valve M-SR shows a pressure drop around 10 bar, which is acceptable in most high-flow circuits.

These performance curves assume the use of HLP 46 hydraulic oil at 40 degrees Celsius. Viscosity changes affect the pressure drop, with thicker fluids creating higher resistance. The valve handles viscosities from 2.8 up to 500 square millimeters per second, though performance outside the typical range should be verified for specific applications.

The reverse sealing performance is essentially perfect. When pressure acts against the closing direction, the poppet seats firmly and prevents leakage. This leak-tight characteristic makes the cartridge valve M-SR suitable for holding pressure in cylinders or preventing reverse flow in pump circuits.

Common Applications and Use Cases

The M-SR cartridge valve finds use across many industries where reliable check valve function is required. In automotive manufacturing, these valves protect transmission test stands and brake system circuits. A typical installation might use an NG 20 cartridge valve M-SR in a transmission test circuit flowing 200 liters per minute, where preventing backflow ensures accurate test results and protects expensive equipment.

Packaging machinery relies on precise cylinder positioning, and the cartridge valve M-SR prevents load drift by blocking reverse flow when the directional valve centers. This application often uses smaller sizes like NG 10 or NG 15, matched to the cylinder flow requirements.

Medical and pharmaceutical equipment demands clean operation without contamination risks. The sealed cartridge design of the M-SR valve eliminates external leakage paths that could introduce contaminants. These systems typically operate at moderate pressures where the 420 bar rating provides ample safety margin.

Industrial machine tools use the cartridge valve M-SR in pump bypass circuits and cylinder load-holding applications. The compact installation saves panel space while delivering reliable performance in demanding production environments. Construction equipment and wind turbine pitch control systems also incorporate these valves for their robust high-pressure capability.

The versatility of the cartridge valve M-SR comes from its simple operation and wide range of sizes. Engineers can specify the exact combination of size, cracking pressure, and seal material to match their specific requirements.

Maintenance Considerations and Service Life

One advantage of the M-SR cartridge valve is its long service life with minimal maintenance. Bosch Rexroth rates the mean time to dangerous failure at 150 years under normal operating conditions, which translates to essentially maintenance-free operation for most installations.

The main service requirement involves maintaining proper fluid cleanliness. The valve requires filtration of 20 micrometers or finer to prevent particle contamination that could damage sealing surfaces. Following ISO 4406 cleanliness level 20/18/15 ensures reliable operation and maximum life.

The threaded plug that seals the cavity is considered a wear item, though replacement is rarely needed unless the valve is removed and reinstalled multiple times. Replacement plugs are available separately using the same part numbers listed for initial installation.

When operating the cartridge valve M-SR in harsh environments with high temperatures, aggressive fluids, or heavy contamination, inspection intervals should be shortened from the standard assumption. Monitoring for external leakage around the threaded plug and checking system pressures periodically helps catch potential issues before failure.

The sealed cartridge design protects internal components from environmental exposure, which contributes to the excellent reliability record. Unlike external check valves that might suffer corrosion or physical damage, the M-SR valve sits protected inside the manifold block.

Comparing Alternatives and Compatible Products

While the Bosch Rexroth M-SR cartridge valve sets the standard for high-pressure check valve performance, several alternatives exist in the market. Understanding the differences helps with sourcing decisions and compatibility questions.

Hydac offers the CSBN series of cartridge check valves with similar screw-in mounting but typically rated to 350 bar instead of 420 bar. These valves cost slightly less while delivering comparable performance in applications that don't require the full pressure rating. Parker makes the D1VW series, which includes electronic monitoring options for systems that need feedback on valve status.

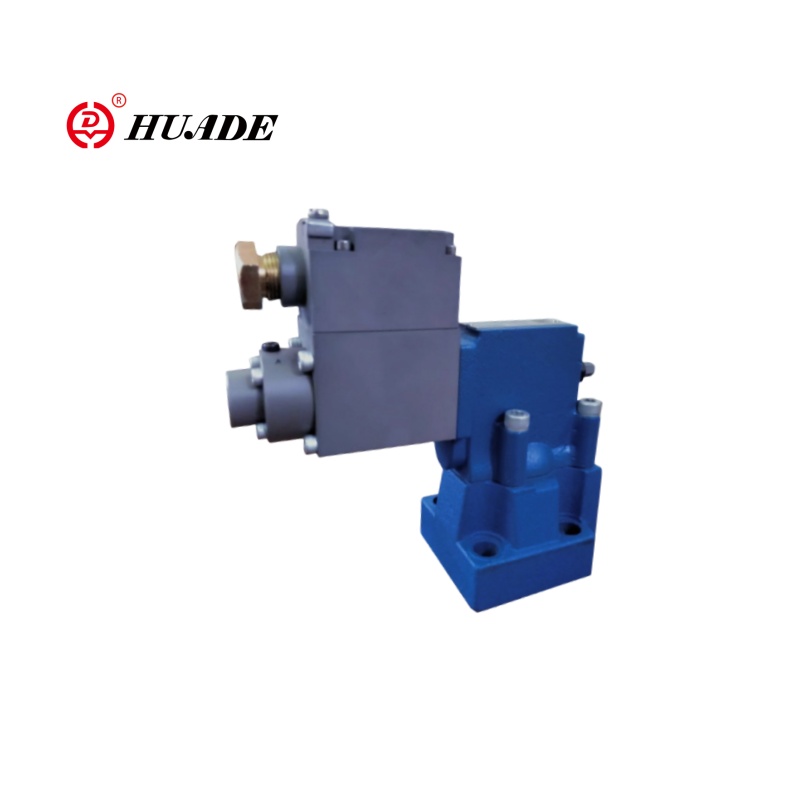

Several manufacturers in China produce cartridge valves compatible with the M-SR specifications. Companies like Huade and Hengli manufacture valves matching the dimensional and performance characteristics at lower price points. These alternatives can work well in non-critical applications or where budget constraints are significant. The key consideration is verifying that the manufacturer maintains proper quality control and provides ISO certification documentation.

When selecting between the original Bosch Rexroth cartridge valve M-SR and compatible alternatives, consider the criticality of the application, required certification levels, and availability of local support. Critical systems that cannot tolerate failure should use original equipment. Less demanding applications might accept compatible products to reduce costs.

Where to Purchase and Pricing Information

The M-SR cartridge valve is available through multiple channels depending on your location and quantity requirements. Bosch Rexroth operates an official online store at [store.boschrexroth.com](http://store.boschrexroth.com/) where standard configurations ship within one to three days. Part numbers follow a specific format, such as R900350797 for an NG 30 KE angle valve with 0.5 bar spring.

Authorized distributors like BuyRexroth provide the cartridge valve M-SR with transparent pricing and worldwide shipping options. These distributors typically stock common sizes and can order special configurations directly from the factory. Lead times for standard parts are usually short, while custom specifications might require several weeks.

Pricing varies significantly by valve size and configuration. Smaller sizes like NG 6 typically cost between 50 and 80 dollars, while large NG 30 valves can reach 200 dollars or more. Compatible alternatives from Chinese manufacturers may price 20 to 40 percent lower, though minimum order quantities might be higher than preferred for small projects.

For specialized applications requiring FKM seals or non-standard cracking pressures, requesting a quote directly from distributors or the manufacturer often yields the best results. Technical support can help confirm that the selected cartridge valve M-SR configuration matches the application requirements before purchase.

Design Considerations for System Integration

Integrating the M-SR cartridge valve into a hydraulic system requires careful attention to manifold design and circuit layout. The valve installs into a standard cavity that must be machined to precise dimensions. Working with manifold suppliers who follow the ZN 10001 standard ensures proper fit and performance.

Flow direction through the cartridge valve M-SR must align with the circuit design. The arrow on the valve body or the catalog symbol indicates the free flow direction. Installing the valve backward will block all flow, so verification during assembly is important. Some engineers mark the manifold block with flow direction arrows to prevent installation errors.

Pressure drop calculations should account for the valve characteristics at expected flow rates. While the pressure drop through the cartridge valve M-SR is typically small compared to other circuit restrictions, high-flow applications benefit from selecting the next larger size to minimize energy loss and heat generation.

The cracking pressure selection affects both forward flow resistance and reverse sealing force. Applications that need minimal forward resistance should use lower cracking pressures like 0.2 bar or even the springless version. Systems that must hold pressure against varying loads benefit from higher cracking pressures that provide stronger sealing.

Temperature cycling and fluid compatibility should be verified during the design phase. If the system will see temperature extremes or uses specialty fluids, confirming seal material compatibility prevents premature failure. The FKM seal option extends chemical resistance for applications involving aggressive additives or elevated temperatures.

Conclusion

The Bosch Rexroth M-SR cartridge valve provides reliable check valve function in a compact package suitable for high-pressure hydraulic systems. Its screw-in cartridge design simplifies installation while eliminating external leakage paths. The range of sizes from NG 6 through NG 30 covers flow requirements from small cylinders to large industrial circuits.

Selecting the right cartridge valve M-SR configuration involves matching the valve size to flow requirements, choosing appropriate cracking pressure for the application, and verifying seal compatibility with operating conditions. The excellent service life and minimal maintenance requirements make this valve a cost-effective choice over the system lifetime.

Whether designing a new hydraulic circuit or replacing existing components, understanding the capabilities and installation requirements of the M-SR cartridge valve helps ensure successful implementation. The widespread availability and extensive application history provide confidence in specifying this proven hydraulic component.