When you're working with hydraulic systems, keeping fluid flowing in the right direction matters more than you might think. The Z1S check valve sandwich plate from Bosch Rexroth does exactly that—it lets fluid pass one way while blocking it from going backward. This simple job is crucial in everything from factory machines to construction equipment.

What Makes the Z1S Check Valve Sandwich Plate Different

The Z1S check valve sandwich plate gets its name from how it installs. Instead of connecting with hoses and fittings, it sits between other components like a sandwich layer. This design saves space and reduces the number of connection points where leaks could happen. The valve uses a spring-loaded poppet mechanism that closes tight against reverse flow, achieving near-zero leakage even when pressure reaches 350 bar.

The check valve sandwich plate design works well in tight spaces. Machine builders often stack multiple Z1S units vertically in hydraulic manifolds, creating complex control circuits without adding bulky external piping. This modular approach follows ISO 4401 standards, which means the Z1S check valve sandwich plate fits with components from various manufacturers.

How the Z1S Check Valve Sandwich Plate Works

Inside every Z1S check valve sandwich plate sits a poppet—usually made from high-performance plastic—held against its seat by a spring. When fluid pressure from the forward direction reaches the cracking pressure threshold, the poppet lifts and fluid flows through. The moment pressure drops or reverses, the spring pushes the poppet back down, sealing the passage.

The Z1S series offers different cracking pressures: 0.5, 1.5, 3, and 5 bar options. Lower cracking pressures work better in systems where you want minimal resistance, while higher settings prevent accidental opening from pressure spikes. The check valve sandwich plate configuration handles flows up to 40 liters per minute in size 6 models and 100 liters per minute in size 10 variants.

Choosing the Right Z1S Check Valve Sandwich Plate

Bosch Rexroth makes eight different closing function variants of the Z1S check valve sandwich plate. Some block flow in one channel while others handle dual channels simultaneously. The most common version blocks flow from port A2 to A1, but you'll find options for nearly any circuit configuration.

Size matters when selecting your check valve sandwich plate. The size 6 Z1S weighs about 0.8 kilograms and handles pressures up to 350 bar. Size 10 units are larger at 2.3 kilograms but can manage 100 liters per minute of flow. Both versions work with mineral hydraulic oils and can be adapted for biodegradable fluids when you choose compatible seals.

The seal material affects performance significantly. Standard FKM seals handle most applications well, especially when fluid velocity exceeds 4 meters per second. For lower pressure and slower flow situations, soft NBR seals reduce wear on mating surfaces. Your check valve sandwich plate will last longer when the seal matches your operating conditions.

Installing Your Z1S Check Valve Sandwich Plate

Getting the installation right determines how well your Z1S check valve sandwich plate performs. The mounting surface needs to be flat within 0.01 millimeters per 100 millimeters and smooth with a surface roughness no greater than 4 micrometers. These specifications might sound precise, but they prevent leaks that could develop over time.

The check valve sandwich plate mounts with four screws—M5 for size 6 or M6 for size 10 models. Torque matters here. Size 6 units need 8 to 10 newton-meters while size 10 requires 15.5 newton-meters plus or minus 10 percent. Using screws with strength class 10.9 ensures the mounting stays secure even under vibration.

You can install the Z1S check valve sandwich plate in any orientation. The design doesn't depend on gravity to function. Just make sure the blue plastic bushing that comes with some models stays protected during assembly. This bushing provides additional sealing and shouldn't be damaged or removed unless you're replacing the entire valve.

Where the Z1S Check Valve Sandwich Plate Works Best

Hydraulic presses rely on check valve sandwich plates to hold loads safely. When the press pauses between cycles, the Z1S prevents fluid from flowing backward, which would let the press ram drift downward. This load-holding function matters for both safety and precision.

Machine tools use the Z1S check valve sandwich plate in CNC spindles and tool changers. The compact sandwich design fits into tight spaces around rotating components. High-velocity circuits in these machines benefit from the valve's metal seal option, which handles speeds above 4 meters per second without excessive wear.

Mobile equipment like excavators and cranes needs reliable flow control in challenging conditions. The Z1S check valve sandwich plate handles the temperature swings and vibration common in construction sites. Angled variants of the check valve sandwich plate help route fluid flow efficiently in the cramped confines of mobile machinery.

Maintaining Your Z1S Check Valve Sandwich Plate

Clean hydraulic fluid keeps your check valve sandwich plate working properly. Bosch Rexroth specifies ISO 4406 contamination class 20/18/15, which requires filtration down to 20 micrometers. Dirty fluid causes the poppet to stick or wear prematurely, leading to leaks or failure to close.

Regular inspections should check for external leaks around the mounting surface and measure pressure drop across the valve. An increase in pressure drop often signals contamination building up inside. The Z1S check valve sandwich plate doesn't offer field repair options—if the internal poppet assembly fails, you replace the entire unit.

Temperature affects how your check valve sandwich plate performs. The Z1S operates from -20°C to +80°C, matching most hydraulic fluid temperature ranges. Fluid viscosity should stay between 2.8 and 500 square millimeters per second. Outside these ranges, the valve may not open at the specified cracking pressure or might develop leaks.

Troubleshooting Common Z1S Check Valve Sandwich Plate Issues

When a check valve sandwich plate won't open, contamination usually causes the problem. Flushing the system according to ISO cleanliness standards often resolves sticking issues. If flushing doesn't work, the spring may have fatigued and needs replacement—which means replacing the whole valve.

Excessive leakage through your Z1S check valve sandwich plate typically points to worn seals or using fluid that's incompatible with the seal material. Check that you're running the correct hydraulic oil type and that seals match your application. Bio-based fluids require different seals than standard mineral oils.

High pressure drop across the valve suggests you might have selected the wrong cracking pressure or that debris is restricting flow. The check valve sandwich plate should show gradual pressure increase with flow rate. A sudden jump in pressure drop indicates internal blockage requiring valve replacement.

Noisy operation often comes from cavitation—when fluid velocity gets too high and creates vapor bubbles that collapse violently. Adding flow damping upstream or switching to a check valve sandwich plate with metal seals can reduce cavitation noise. Sometimes increasing system pressure eliminates the conditions that cause cavitation.

Comparing the Z1S Check Valve Sandwich Plate to Other Options

Inline check valves cost less than sandwich plates but take up more space and need additional hose connections. The Z1S check valve sandwich plate integrates directly into your valve stack, eliminating four hose ends and their potential leak points. For manifold-mounted systems, the sandwich design makes more sense.

Pilot-operated check valves offer remote control capabilities that the Z1S check valve sandwich plate lacks. However, they require additional pilot lines and control valves, adding complexity your system might not need. For simple one-way flow control, the direct-operated Z1S provides reliable performance without extra components.

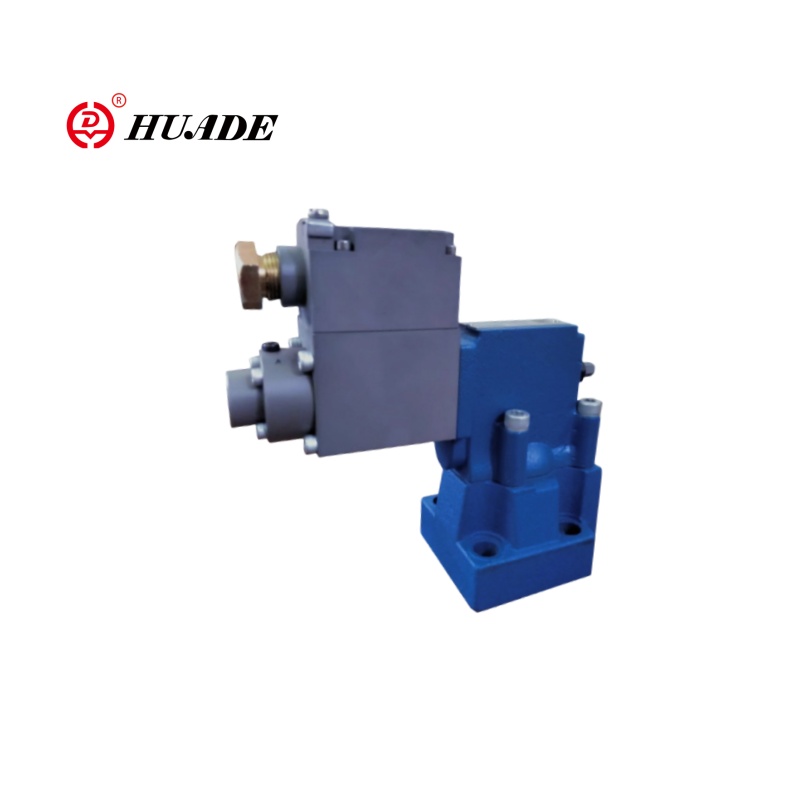

Alternative manufacturers like Huade and Hengli produce check valve sandwich plates compatible with ISO 4401 standards. These options can cost 30 to 50 percent less than genuine Bosch Rexroth units. The quality usually meets requirements for non-critical applications, but original Z1S valves offer proven reliability in demanding environments.

Getting the Most from Your Z1S Check Valve Sandwich Plate

The Z1S check valve sandwich plate delivers reliable one-way flow control when you match the valve to your application. Choosing the right cracking pressure, seal type, and size ensures optimal performance. Proper installation with correct torque and surface preparation prevents leaks. Maintaining clean fluid and staying within temperature limits extends service life.

This check valve sandwich plate works in systems ranging from 0.5 bar to 350 bar pressure and handles mineral oils or biodegradable fluids with appropriate seals. The compact sandwich mounting reduces space requirements while providing leak-free operation. Whether you're designing a new hydraulic system or upgrading an existing one, the Z1S check valve sandwich plate offers a proven solution for directional flow control.

For detailed specifications and ordering information, Bosch Rexroth provides comprehensive datasheets through their distributors. Taking time to review these documents helps you select the exact Z1S check valve sandwich plate variant your application requires.