When working with hydraulic systems, you need components that keep fluids flowing in the right direction. The Check Valve RVP 25 is a reliable device designed to do exactly that. This valve lets hydraulic oil flow freely in one direction while blocking any backward flow. It's a simple concept, but the Check Valve RVP 25 does this job extremely well in medium to high-pressure systems.

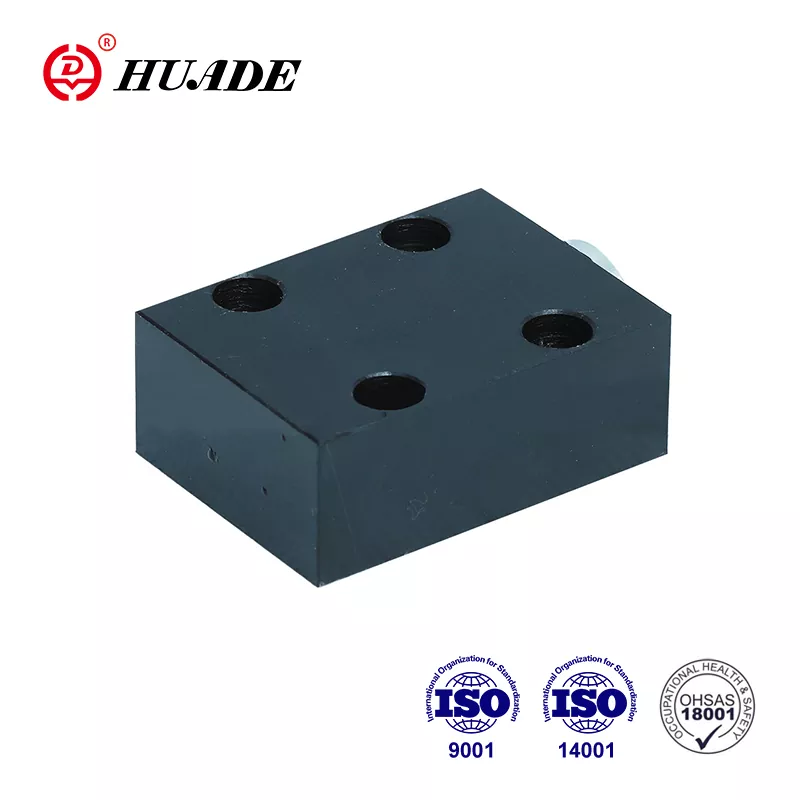

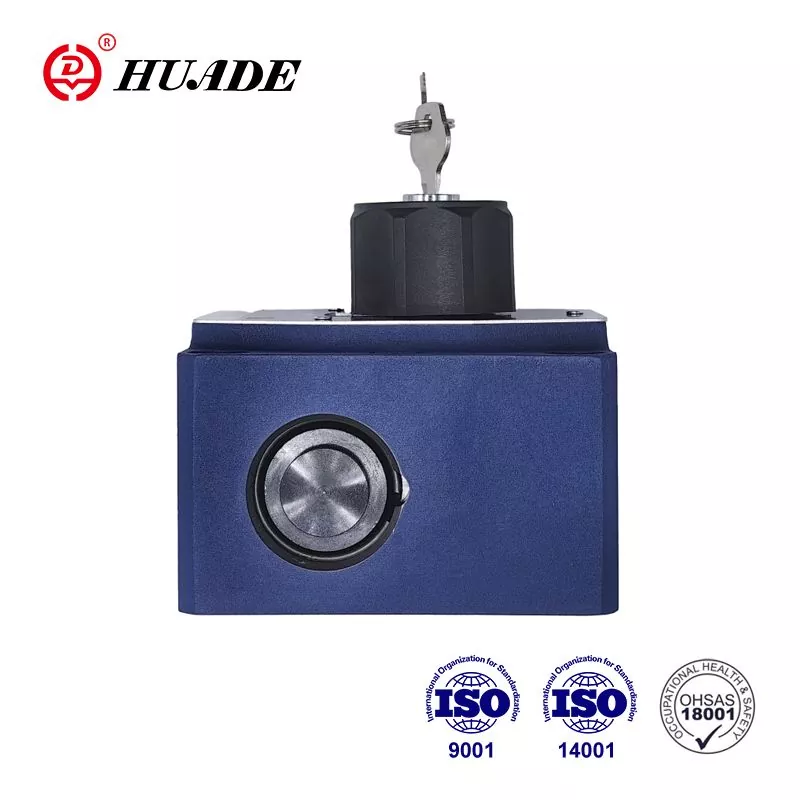

The RVP 25 belongs to a family of check valves made by well-known European manufacturers like HYDAC and MHA Zentgraf. You can also find compatible versions from companies like Huade and Hengli. These valves mount directly onto manifolds, which are metal blocks that organize hydraulic connections. This design saves space and makes installation cleaner than using individual pipe fittings.

The number "25" refers to the valve's nominal size, which is DN25 or roughly one inch in diameter. This size handles medium to large flow rates, typically between 150 and 550 liters per minute. That's enough for construction equipment, industrial machines, and automated systems. The Check Valve RVP 25 works best in applications where you need consistent one-way flow without frequent cycling.

How the Check Valve RVP 25 Actually Works

Inside the Check Valve RVP 25, you'll find a few basic parts working together. There's a valve body, a cone-shaped seat, a moving piston or ball, a spring, and rubber seals called O-rings. The design is straightforward, which makes it reliable.

When hydraulic fluid pushes through the valve in the correct direction, the pressure overcomes the spring force. This pushes the piston away from its seat, creating an opening for fluid to pass through. The pressure drop during this forward flow is relatively low, usually just a few bars even at high flow rates. This efficiency means your pump doesn't work harder than necessary.

When fluid tries to flow backward, the spring immediately pushes the piston back against the seat. The cone shape creates a tight seal, and the reverse pressure actually helps press the seal even tighter. This metal-to-metal contact stops almost all leakage. According to industry standards like DIN EN 12266, the Check Valve RVP 25 achieves what's called "zero leakage" classification, though some minimal seepage is normal in real-world conditions.

Different manufacturers use slightly different internal designs. HYDAC versions typically use a cone-shaped piston for precision control. Zentgraf models often use a ball design, which responds faster at lower pressures. Both approaches work well, but the cone design generally provides tighter tolerances. The Check Valve RVP 25 from either manufacturer handles mineral-based hydraulic oils with viscosity between 2.8 and 500 square millimeters per second. You'll want to keep your hydraulic fluid filtered to at least 20 microns to prevent contamination inside the valve.

Technical Specifications That Matter

Understanding the specifications of the Check Valve RVP 25 helps you choose the right valve for your system. The working pressure is one of the most important numbers. Most RVP 25 valves handle up to 350 bar, which equals about 5,000 pounds per square inch. Some versions from suppliers like Huade and Hengli are rated for 315 bar, which is still plenty for most applications. This pressure rating applies when you're using standard mineral oil at normal temperatures.

The maximum flow rate varies slightly between manufacturers. HYDAC rates their Check Valve RVP 25 at 150 gallons per minute or about 568 liters per minute. Zentgraf and compatible Chinese manufacturers claim flow rates between 400 and 550 liters per minute. The actual flow your system can handle depends on how much pressure drop you can accept. At higher flow rates, the pressure drop increases, which can affect overall system efficiency.

Opening pressure, also called cracking pressure, determines when the Check Valve RVP 25 starts to open. Standard versions open at about 7 psi or 0.5 bar. This is low enough that the valve doesn't create unnecessary resistance during normal operation. However, you can order versions with higher opening pressures, ranging from 25 psi up to 65 psi or 4.5 bar. Higher opening pressures work better in systems where you need to prevent any slight backflow, even under minimal reverse pressure. Keep in mind that manufacturers allow a tolerance of plus or minus 30 percent on these opening pressure values.

Temperature range is another practical consideration. The Check Valve RVP 25 operates safely from negative 20 degrees Celsius to positive 100 degrees Celsius. That's negative 4 degrees Fahrenheit to 212 degrees Fahrenheit. These limits come from the rubber O-rings, which are typically made from FPM or NBR materials. FPM handles higher temperatures better, while NBR costs less and works fine in moderate conditions.

The valve body itself is made from carbon steel, often with a phosphate coating to resist corrosion. The moving piston or ball uses hardened steel to withstand millions of cycles without wearing down. Some manufacturers offer zinc plating as an alternative surface treatment. These material choices make the Check Valve RVP 25 durable in dirty industrial environments.

Connection options include NPT threads, SAE O-ring ports, and BSPP threads. However, most users install the Check Valve RVP 25 directly onto a manifold using bolts rather than threaded connections. This mounting style is cleaner and more reliable for systems with multiple valves.

Physical Dimensions and Installation Requirements

Getting the dimensions right matters when you're integrating the Check Valve RVP 25 into your hydraulic manifold. The valve measures approximately 172 millimeters long, 79.5 millimeters high, and varies in width depending on the specific model. That's about 6.8 inches long and 3.1 inches tall. The mounting face where the valve bolts to the manifold is 165 millimeters long and 120 millimeters wide on HYDAC versions.

The ports where fluid enters and exits are spaced 100 millimeters apart from center to center. This is a standard spacing used across many hydraulic components, which makes it easier to design manifolds that accommodate multiple valves. The port diameter itself is 28 millimeters, suitable for one-inch fittings.

You'll need to drill mounting holes in your manifold to accept the Check Valve RVP 25. These holes should be 11.5 millimeters in diameter, spaced 60 millimeters apart. Most installations use four to six M10 bolts, which are 10 millimeters in diameter. The recommended torque for these bolts is 70 Newton-meters, which ensures a tight seal without damaging the valve body or manifold. Over-tightening can crack the housing or deform the sealing surface.

Before you install the Check Valve RVP 25, check that your manifold mounting surface is flat and smooth. The surface roughness should be better than 0.8 micrometers, and the flatness should be within 0.01 millimeters per 100 millimeters of length. These tight tolerances prevent leaks around the O-ring seal. A standard O-ring size for the RVP 25 is 32 millimeters by 3 millimeters cross-section.

When you're ready to install, apply a thin layer of compatible hydraulic oil or grease to the O-ring. This lubrication helps the O-ring seat properly without twisting or pinching. Place the Check Valve RVP 25 onto the manifold and hand-start all the mounting bolts. Then tighten them gradually in a crisscross pattern, similar to how you'd tighten wheel lug nuts on a car. This even tightening prevents warping the valve body.

The Check Valve RVP 25 can be installed in any orientation. You can mount it horizontally, vertically, or at an angle. Just make sure the flow direction matches the arrow marked on the valve body. The arrow shows the free-flow direction, where fluid should enter at port P1 and exit at port P2. Installing the valve backward will prevent all flow, which could damage your pump or other components.

Weight is another consideration if you're designing a mobile system. The Check Valve RVP 25 weighs approximately 5.8 kilograms, which is about 12.8 pounds. This includes the valve body and standard mounting hardware. Larger versions with different port configurations might weigh slightly more.

Comparing Different Manufacturers and Suppliers

Several companies manufacture the Check Valve RVP 25 or compatible equivalents. Understanding the differences helps you make a smart purchasing decision based on your budget and performance needs.

HYDAC is probably the most recognized name in hydraulic check valves. Their Check Valve RVP 25 offers the widest range of opening pressure options, from 7 psi up to 65 psi. HYDAC valves undergo rigorous testing and come with ISO 9001 certification. You'll find HYDAC products through distributors like ValinOnline and Motion Industries across North America and Europe. The downside is cost. HYDAC Check Valve RVP 25 units typically run between 300 and 500 US dollars depending on configuration. However, availability is excellent, and you can usually get replacement parts quickly.

MHA Zentgraf produces Check Valve RVP 25 models primarily for the European market. Their valves use a ball-type design instead of a cone piston, which some engineers prefer for lower opening pressures. Zentgraf valves are compact and work well in tight spaces. They meet DIN standards and offer customization options. Pricing falls between 200 and 400 dollars. You can find Zentgraf valves through DirectIndustry and sometimes on eBay, though availability outside Europe can be limited.

Chinese manufacturers like Huade and Hengli make compatible versions of the Check Valve RVP 25 at much lower prices. Huade markets their valves as Rexroth-compatible, which means they'll physically fit in places designed for Rexroth components. Prices start around 42 dollars FOB from China, though you'll need to account for shipping and import duties. Minimum order quantities are often just one piece, making Huade attractive for small projects or repairs. Hengli offers similar pricing and adds options like enhanced corrosion resistance through special coatings.

Quality differences do exist between premium and budget brands. HYDAC and Zentgraf valves typically have tighter manufacturing tolerances, which means more consistent opening pressures and longer service life. Chinese-made Check Valve RVP 25 units work fine for many applications, but you might see more variation from valve to valve. If you're building a critical system where failure could be dangerous or expensive, paying extra for a HYDAC or Zentgraf valve makes sense. For general industrial equipment with less demanding requirements, Huade or Hengli valves provide good value.

All these manufacturers offer ISO 9001 certification, which means they follow quality management standards. Some also carry environmental certifications like ISO 14001 and safety certifications like ISO 45001. When ordering, verify that your supplier can provide material certificates and test reports if you need them for regulatory compliance.

Real-World Applications of the Check Valve RVP 25

The Check Valve RVP 25 appears in many types of hydraulic equipment across different industries. Understanding these applications helps you see where this valve fits into real systems.

Construction and earthmoving equipment uses the Check Valve RVP 25 extensively. Excavators, for example, have hydraulic arms that need to hold their position when the operator stops moving the controls. A Check Valve RVP 25 installed at the cylinder prevents oil from flowing backward, which would let the arm drop. This load-holding function keeps operators safe and allows precise control. Similar applications appear in bulldozers, cranes, and forklifts.

Manufacturing machinery benefits from Check Valve RVP 25 installations in several ways. CNC machining centers use hydraulic clamps to hold workpieces steady during cutting operations. Check valves ensure the clamps stay tight even if pump pressure fluctuates. Injection molding machines pump hot plastic into molds under high pressure. The Check Valve RVP 25 prevents plastic from flowing backward through the injection circuit, which would waste material and slow production.

Metal processing equipment like presses and shears generates enormous forces through hydraulic cylinders. These systems need reliable check valves to prevent uncontrolled movement when the operator releases the controls. The Check Valve RVP 25 handles the high pressures and flow rates typical in metalworking applications. Its low pressure drop means the system remains efficient even during rapid cycles.

Agricultural equipment including tractors and harvesters incorporates hydraulic systems for implements and steering. The Check Valve RVP 25 protects hydraulic pumps from reverse rotation damage that could occur when the tractor engine shuts off. The valve also helps maintain pressure in lift circuits, preventing implements from slowly drifting down when parked on slopes.

Automated production lines often use hydraulic power for repetitive tasks like stamping, pressing, and material handling. The Check Valve RVP 25 fits into manifold blocks that control multiple cylinders from a central location. This organized approach reduces piping, saves space, and simplifies troubleshooting. Flow rates up to 550 liters per minute make the RVP 25 suitable even for fast production equipment.

One specific example involves a robotic assembly system where the Check Valve RVP 25 works alongside pressure relief valves in a compact manifold. The robot arm moves quickly and precisely, requiring flow rates around 600 liters per minute. By installing the Check Valve RVP 25, the engineers achieved 15 percent better system efficiency compared to their previous setup. The low pressure drop meant the pump used less energy, reducing operating costs.

Stationary hydraulic power units in factories often incorporate Check Valve RVP 25 units at pump outlets. This prevents system pressure from backflowing through the pump when it stops, which could cause damage. The valve also allows smoother starts because the pump doesn't have to overcome system pressure immediately. This application is simple but critical for reliability.

Maintenance and Troubleshooting Your Check Valve RVP 25

Regular maintenance keeps your Check Valve RVP 25 working properly for years. The good news is that these valves need minimal attention if installed correctly and operated within their design limits.

Start with a visual inspection every six to twelve months, depending on how hard your system works. Look for any oil leaking around the valve body or mounting surface. A few drops might indicate a worn O-ring that needs replacement. Heavy leaking could mean the mounting bolts have loosened or the manifold surface is damaged. Check that all mounting bolts remain tight at the specified 70 Newton-meter torque.

Testing the opening pressure tells you if the internal spring is still working correctly. You'll need a test bench with adjustable pressure and flow controls. Connect the Check Valve RVP 25 to the test bench and gradually increase pressure in the forward direction. Note the pressure at which flow begins. Compare this to the valve's specification. If the opening pressure has increased significantly, the valve might have contamination holding the piston off its seat. If opening pressure has decreased, the spring may be weakening from fatigue or corrosion.

Internal cleaning becomes necessary if you notice that the Check Valve RVP 25 is sticking or responding slowly. Remove the valve from the manifold and disassemble it carefully. Some valves require special tools to avoid damaging internal parts. Clean all components with a solvent that's compatible with your hydraulic fluid. Mineral spirits work well for mineral oil systems. Inspect the cone seat and piston for wear or scratches. Even small imperfections can cause leakage. Check the spring for corrosion or permanent deformation.

Replace the O-rings during any major service. These rubber seals lose flexibility over time, especially if exposed to temperature extremes or incompatible fluids. Use genuine replacement O-rings that match the original material. FPM O-rings cost more than NBR but last longer in hot conditions. Apply a thin coat of hydraulic fluid to new O-rings during assembly.

The valve cartridge inside the Check Valve RVP 25 is replaceable on most models. If you find significant wear or damage, ordering a new cartridge is often more economical than trying to repair individual components. Make sure replacement parts come from the original manufacturer or a verified compatible source. Generic parts might not meet the same tolerance specifications.

Store spare Check Valve RVP 25 units in a clean, dry location. Seal the ports with plastic caps to prevent contamination. Extreme temperature storage can damage O-rings, so keep spares in a climate-controlled area if possible. Check stored valves annually and replace any O-rings that show signs of deterioration.

Important Operating Considerations

Several factors affect how well the Check Valve RVP 25 performs in your specific system. Understanding these considerations helps you avoid problems.

Cycle frequency matters more than most people realize. The Check Valve RVP 25 handles occasional cycling very well, but it's not designed for rapid, continuous operation. Manufacturers typically specify a maximum cycle life of 10,000 operations for standard versions. If your application cycles more frequently, the spring and sealing surfaces will wear faster. Consider a pilot-operated check valve for high-cycle applications instead.

Fluid viscosity changes the pressure drop through the Check Valve RVP 25. The specifications assume mineral oil with viscosity around 335 SUS, which is typical for industrial hydraulics. Thicker fluids create higher pressure drops, which reduces system efficiency and generates more heat. Thinner fluids might not lubricate internal parts adequately, causing faster wear. Stick to the specified viscosity range of 2.8 to 500 square millimeters per second for best results.

Contamination is a major enemy of all hydraulic valves, including the Check Valve RVP 25. The tight clearances inside the valve can't tolerate dirt or metal particles. Always filter your hydraulic fluid to at least 20 microns, and preferably 10 microns or finer. Install the filter upstream of the Check Valve RVP 25 to catch contamination before it reaches the valve. Change filters regularly according to the manufacturer's schedule.

Temperature extremes affect both performance and lifespan. While the Check Valve RVP 25 operates from negative 20 to positive 100 degrees Celsius, staying toward the middle of this range is better. Very cold temperatures make seals stiff and can increase opening pressure. Very hot temperatures soften seals and accelerate wear. If your system runs consistently hot, consider upgrading to FPM O-rings or adding a heat exchanger to your hydraulic circuit.

Installation orientation doesn't affect the Check Valve RVP 25 mechanically, but it can matter for maintenance access. Mount the valve where you can reach the mounting bolts for future service. If possible, orient it so any trapped air bubbles can escape naturally. While the valve works in any position, mounting it with ports horizontal makes bleeding air easier during initial startup.

System pressure spikes can damage any hydraulic component, including check valves. Make sure your system includes adequate pressure relief valves sized for your pump's flow rate. The Check Valve RVP 25 is rated for 350 bar continuous pressure, but repeated spikes above this rating will shorten its life. Consider installing pressure dampeners or accumulators if your system experiences frequent pressure surges.

Selecting the Right Check Valve RVP 25 for Your System

Choosing the correct valve specification requires matching the valve capabilities to your system requirements. Start by identifying your system's maximum operating pressure. Add a safety margin of at least 20 percent to account for pressure spikes. If your system normally runs at 280 bar, the 350 bar rating of the Check Valve RVP 25 provides adequate margin. For higher pressures, you'd need a different valve series.

Flow rate calculation comes next. Determine the maximum flow through the circuit where you'll install the Check Valve RVP 25. Compare this to the valve's flow rating, typically 150 to 550 liters per minute depending on manufacturer. Don't forget to check the pressure drop curves. Higher flow rates cause larger pressure drops, which waste energy and generate heat. If your required flow creates more than 10 bar pressure drop, consider a larger valve size or two valves in parallel.

Opening pressure selection depends on your specific application. For most uses, the standard 0.5 bar opening pressure works well. This low setting minimizes resistance during normal operation. However, you might need higher opening pressure in certain situations. If you're trying to hold a load vertically, higher opening pressure provides better security against drift. If you need to prevent any backflow whatsoever, even slight backpressure, choose a 4.5 bar opening pressure. Remember that higher opening pressures also increase the forward pressure drop.

Port configuration must match your manifold or piping. The Check Valve RVP 25 comes with various port options including NPT threads, SAE O-ring ports, and BSPP threads. For manifold mounting, verify that the port spacing and mounting hole pattern match your manifold design. Most manufacturers provide CAD models you can import into your design software to verify fit. Download these models before finalizing your purchase.

Material compatibility is crucial for long valve life. The standard Check Valve RVP 25 works with mineral-based hydraulic oils and phosphate ester fluids. If you're using water-glycol mixtures, synthetic fluids, or biodegradable oils, verify compatibility with both the valve body and seals. Some manufacturers offer special seal materials for unusual fluids. When in doubt, contact the manufacturer's technical support for guidance.

Budget considerations affect your choice of brand. If cost is your primary concern and your application isn't critical, the Huade or Hengli versions of the Check Valve RVP 25 offer substantial savings. For demanding applications where reliability is paramount, HYDAC or Zentgraf valves justify their higher cost through better consistency and support. Consider the total cost of ownership, including potential downtime if a valve fails, not just the initial purchase price.

Lead time and availability matter for project planning. HYDAC valves are readily available in North America and Europe, often shipping within days. Chinese manufacturers might require several weeks for delivery, especially if you need customization. Plan your ordering accordingly to avoid project delays.

How the Check Valve RVP 25 Compares to Other Options

Understanding alternatives helps you confirm that the Check Valve RVP 25 is the right choice for your application. Several other valve types provide one-way flow control, each with different strengths.

Standard inline check valves like the RV series use the same basic principle as the RVP 25 but connect with threaded ports instead of bolting to a manifold. The RV series works fine for simple piping systems, but the Check Valve RVP 25 saves considerable space in manifold designs. You can package multiple RVP 25 valves in a compact block instead of running pipes to individual RV valves. This reduces leak points and makes the system more organized. However, if you're retrofitting an existing pipe system, RV valves might be easier to install than redesigning for manifold mounting.

Pilot-operated check valves offer an additional control port that allows you to open the valve even against reverse pressure. This feature is useful when you need to retract a cylinder that's been locked by a check valve. The Check Valve RVP 25 doesn't have this pilot function, making it simpler and less expensive. If you definitely need pilot operation, you'll want a different valve type. But for basic one-way flow control, the simpler Check Valve RVP 25 is more reliable because it has fewer parts to fail.

Ball-type check valves from manufacturers like Zentgraf respond very quickly because the ball has less mass than a cone piston. This fast response works well in systems with rapid pressure changes. However, cone designs like those used in HYDAC Check Valve RVP 25 units typically seal better because the cone provides more contact area with the seat. The cone design also handles high pressures more reliably over millions of cycles. Your choice between ball and cone depends on whether you need faster response or better sealing.

Proportional valves provide variable flow control instead of simple on-off operation. These are completely different from check valves and serve a different purpose. Don't confuse the two. Proportional valves cost much more and require electronic controls. The Check Valve RVP 25 is a passive device that works automatically based on pressure difference. This simplicity makes it extremely reliable and suitable for basic flow control tasks.

Spring-loaded relief valves look similar to check valves but serve a different function. Relief valves protect systems from overpressure by opening when pressure exceeds a set limit. The Check Valve RVP 25 operates based on flow direction, not pressure level. Many systems use both types of valves together. The Check Valve RVP 25 prevents backflow while relief valves handle pressure spikes.

Future Trends and Technology Integration

Hydraulic technology continues to evolve, and the Check Valve RVP 25 is adapting along with the industry. Some manufacturers are now offering check valves with integrated sensors that monitor flow, pressure, and temperature. These smart valves connect to industrial Internet of Things networks, allowing real-time system monitoring. While sensor integration isn't common yet in the RVP 25 specifically, it represents where the technology is heading. Predictive maintenance becomes possible when you can track valve performance remotely.

Material science improvements are making hydraulic components last longer in harsh environments. New seal materials resist higher temperatures and aggressive fluids better than traditional rubber. Surface treatments on valve bodies provide better corrosion resistance without adding much cost. As these technologies mature, we can expect Check Valve RVP 25 units to handle increasingly demanding applications.

Miniaturization is another trend affecting hydraulic valves. As mobile equipment becomes more compact, there's pressure to shrink hydraulic components while maintaining performance. The manifold-mounted design of the Check Valve RVP 25 already addresses this need better than traditional inline valves. Future versions might pack even more functionality into smaller packages through advanced manufacturing techniques like additive manufacturing.

Final Thoughts on the Check Valve RVP 25

The Check Valve RVP 25 represents a mature, reliable solution for one-way flow control in medium-pressure hydraulic systems. Its straightforward design provides consistent performance across a wide range of applications, from construction equipment to automated manufacturing. The valve's ability to handle up to 350 bar pressure and 550 liters per minute flow makes it suitable for demanding industrial use.

Choosing between manufacturers comes down to balancing cost against quality requirements. HYDAC offers premium performance and widest availability. Zentgraf provides European engineering with good customization. Huade and Hengli deliver functional performance at budget prices. All these options give you flexibility to match valve choice to project requirements.

Proper installation and maintenance ensure long service life. Mount the Check Valve RVP 25 on a flat, clean manifold surface with correctly torqued bolts. Keep hydraulic fluid clean and within the specified temperature range. Check opening pressure periodically and replace O-rings during major service intervals.

For detailed specifications and CAD models, visit manufacturer websites like HYDAC's official site or engineering platforms like DirectIndustry. If you're ready to purchase, suppliers like ValinOnline, Motion Industries, and Made-in-China offer various pricing options. Whether you're designing a new system or replacing a worn valve, the Check Valve RVP 25 provides proven performance you can count on.