When you're working with hydraulic systems, understanding each component matters. The Check Valve RVP 30 stands out as a reliable solution for controlling fluid flow in one direction. This hydraulic check valve, manufactured by HYDAC, has become a standard choice in industrial and mobile machinery applications.

What Is the Check Valve RVP 30?

The Check Valve RVP 30 is a manifold-mounted directional control valve designed for hydraulic oil systems. It allows fluid to flow freely from port B to port A while completely blocking any reverse flow. This one-way flow control is essential in many hydraulic applications where preventing backflow protects pumps and maintains system pressure.

The RVP 30 uses a spring-loaded poppet design made from hardened steel. When fluid pressure from the B port exceeds the spring force, the valve opens and lets fluid pass through. When pressure drops or tries to reverse direction, the spring pushes the poppet back against the seat, creating a metal-to-metal seal that prevents any leakage.

This check valve follows DIN ISO 1219 standards and is specifically designed for mounting directly onto hydraulic manifolds or mounting plates. The compact design saves space compared to inline check valves, making the RVP 30 ideal for systems where installation room is limited.

Technical Specifications That Matter

The Check Valve RVP 30 handles demanding conditions with specifications that meet industrial requirements. The valve operates at a maximum working pressure of 350 bar, which equals approximately 5000 psi. This pressure rating makes the RVP 30 suitable for high-pressure hydraulic circuits commonly found in heavy equipment.

Flow capacity reaches up to 600 liters per minute or about 150 gallons per minute. This high flow rate means the Check Valve RVP 30 can handle substantial fluid volumes without creating excessive pressure drop. The standard cracking pressure is 0.5 bar, though options exist for 0.05 to 4.5 bar depending on application needs. Lower cracking pressures allow the valve to open more easily, while higher settings provide better sealing against backflow.

The valve body is made from carbon steel with phosphate or zinc plating for corrosion resistance. The poppet itself uses hardened and polished steel for durability. Standard seals are FKM fluoroelastomer, which handles temperatures from negative 20 degrees Celsius to positive 80 degrees Celsius. Some versions extend the lower range to negative 30 degrees Celsius.

The RVP 30 weighs about 10.3 kilograms and connects through threaded ports sized for 1.5 inch NPTF, BSPP, or SAE O-ring fittings. The mounting pattern uses four bolts and can be installed in any orientation without affecting performance.

How the Check Valve RVP 30 Works in Real Applications

Understanding where the Check Valve RVP 30 fits helps clarify its value. One common application is pump protection. When a hydraulic pump shuts down, fluid can try to flow backward through the pump. This reverse flow can damage pump components or allow system pressure to drop suddenly. Installing the RVP 30 at the pump outlet prevents this backflow and protects the pump from damage.

Accumulator circuits also benefit from the Check Valve RVP 30. Accumulators store pressurized fluid for quick release when needed. The check valve maintains pressure in the accumulator by preventing fluid from flowing back into the main system when pressure drops. This keeps stored energy available for the next work cycle.

Mobile machinery like excavators and loaders use the RVP 30 throughout their hydraulic systems. These machines operate in harsh conditions with constant vibration and varying loads. The check valve's metal-to-metal seal maintains zero leakage even when components heat up during heavy use. This reliability reduces downtime by an estimated 20 to 30 percent compared to systems using lower-quality check valves.

Manufacturing production lines incorporate the Check Valve RVP 30 in presses, injection molding machines, and automated assembly equipment. The valve's quick response time and low pressure drop help these systems operate smoothly without wasting energy. The same principles apply in wind turbine pitch control systems and marine equipment where reliability cannot be compromised.

Pressure Drop Characteristics

Every valve creates some resistance to flow, which shows up as pressure drop. The Check Valve RVP 30 minimizes this energy loss through its streamlined internal design. At 100 liters per minute, pressure drop measures about 0.5 bar. This increases to approximately 1.2 bar at 200 liters per minute and reaches about 4.8 bar at the maximum flow rate of 600 liters per minute.

These pressure drop values are relatively low for a check valve of this size and capacity. Lower pressure drop means less energy wasted as heat and more efficient system operation. The relationship between flow rate and pressure drop is not linear, with pressure drop increasing more rapidly at higher flow rates due to turbulence and friction.

System designers can use these pressure drop figures to calculate total system losses and size pumps appropriately. The Check Valve RVP 30 contributes minimally to overall system inefficiency, which matters when optimizing energy consumption in large industrial installations.

Comparing the RVP 30 to Alternatives

The hydraulic valve market offers many check valve options. The Check Valve RVP 30 competes primarily on reliability and performance rather than price. Bosch Rexroth produces similar valves rated for comparable pressure and flow, sometimes with electronic monitoring capabilities that appeal to automated systems. Parker Hannifin offers check valves that are slightly lighter and easier to integrate into compact designs.

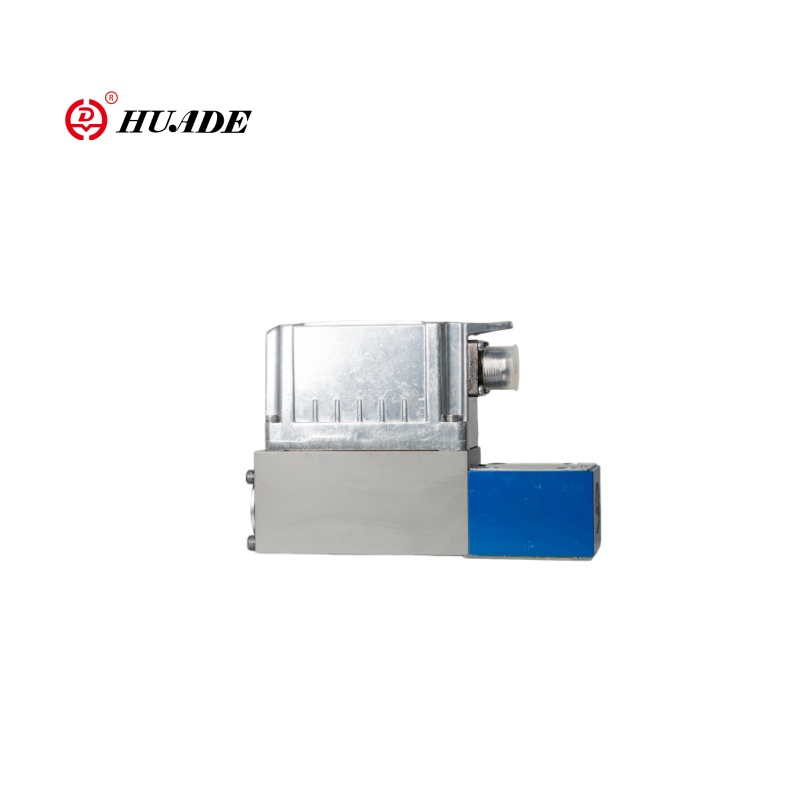

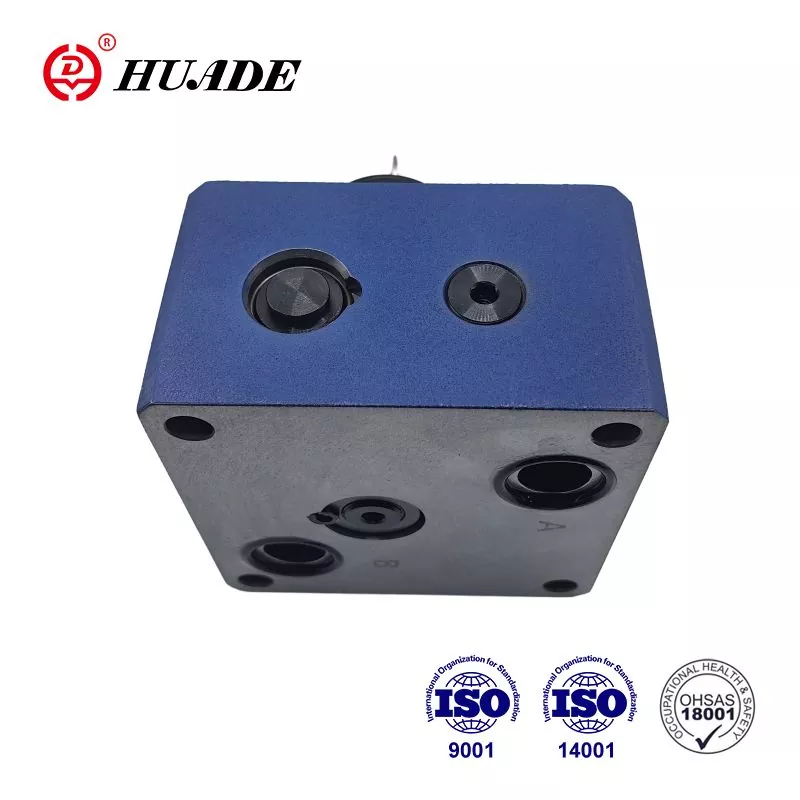

Chinese manufacturers like Huade produce check valves matching the RVP 30 specifications at prices 30 to 50 percent lower. These alternatives meet ISO certification standards and work well in applications where budget constraints matter more than brand heritage. The trade-off typically involves less comprehensive technical support and potentially shorter service life under extreme conditions.

Eaton Vickers check valves provide good compatibility with SAE standard components and maintain wide availability through distribution networks. The Check Valve RVP 30 distinguishes itself through HYDAC's engineering precision and the 150-year Mean Time To Failure calculation. This longevity projection comes from extensive testing and field data from thousands of installations.

For applications requiring absolute reliability, such as offshore oil platforms or critical manufacturing processes, the RVP 30 justifies its premium pricing. For general industrial use with regular maintenance access, less expensive alternatives may provide adequate performance.

Installation Guidelines

Proper installation ensures the Check Valve RVP 30 performs as designed. The mounting surface must be flat within 0.01 millimeters per 100 millimeters and smooth to a surface finish of 0.8 micrometers or better. These specifications prevent leakage around the valve body and ensure even load distribution across mounting bolts.

Thread type must match the system connections, whether NPTF, BSPP, or SAE. Using the wrong thread standard can cause cross-threading or improper sealing. Apply thread sealant appropriate for hydraulic systems, avoiding products that can contaminate the fluid or degrade under pressure.

Mounting bolts should be grade 10.9 or equivalent and tightened in a cross pattern to the torque values specified in the HYDAC installation manual. Uneven tightening can warp the mounting surface and create leak paths. The Check Valve RVP 30 can be installed in any orientation since it uses spring pressure rather than gravity for sealing.

Upstream filtration is critical for valve longevity. The system should filter particles down to 20 micrometers or smaller to meet the ISO 4406 cleanliness level of 21/19/16 specified for the RVP 30. Contamination is the leading cause of check valve failure, with particles preventing the poppet from sealing properly or scoring the sealing surfaces.

After installation, bleed all air from the system before applying full pressure. Trapped air can cause erratic valve operation and excessive noise. Test the check valve by pressurizing from both directions to confirm it opens freely in the forward direction and seals completely against reverse flow.

Maintenance and Troubleshooting

The Check Valve RVP 30 requires minimal maintenance when operated within specifications. Inspection intervals of 1000 to 2000 operating hours are typical for industrial applications. During inspection, check for external leakage around the valve body and mounting surface. Any visible leakage indicates seal wear or improper installation.

Testing cracking pressure periodically verifies the spring has not weakened or the poppet has not worn. If cracking pressure has increased significantly, internal contamination may be preventing full valve opening. If cracking pressure has decreased, spring fatigue or seal degradation may be occurring.

The most common problem with the Check Valve RVP 30 is poppet sticking, where the valve fails to open or close properly. This usually results from contamination lodging between the poppet and seat. Flushing the system with clean hydraulic fluid often resolves minor sticking. Severe contamination requires valve disassembly and cleaning or seal kit replacement.

HYDAC provides seal kits specifically for the RVP 30, including all O-rings and backup rings. Replacing seals typically takes less than an hour with basic hand tools. The seal kit part number for FKM seals is SEAL KIT 30FKM. Always use genuine HYDAC seal kits or verified equivalents to maintain valve performance.

Operating the Check Valve RVP 30 beyond its temperature range can damage seals and cause leakage. FKM seals handle most mineral oil hydraulics applications, but incompatible fluids like certain synthetic oils may require NBR seals instead. Always verify fluid compatibility before installation.

Where to Buy the Check Valve RVP 30

Purchasing options for the Check Valve RVP 30 include authorized distributors and online suppliers. The HYDAC official website provides direct ordering for the RVP-30-01.X model designation with delivery in 2 to 4 weeks globally. This ensures authentic components with full manufacturer warranty and technical support access.

Industrial suppliers like MROstop and Motion Industries stock the Check Valve RVP 30 with pricing around 600 to 850 US dollars for standard configurations. These distributors often maintain inventory for immediate shipment, which helps when replacement valves are needed quickly to minimize downtime.

Online marketplaces including eBay list new RVP 30 valves from various sellers. Prices range from approximately 593 to 857 dollars depending on seller and specific model configuration. Buyer protection programs reduce the risk when purchasing through these channels, though verifying seller reputation remains important.

For customers considering cost alternatives, Alibaba connects buyers with manufacturers like Huade who produce RVP 30 compatible check valves. Prices typically run 30 to 50 percent below HYDAC originals with minimum order quantities of 1 to 10 pieces. Delivery times of 1 to 2 weeks and one-year warranties are standard. SSL payment encryption protects transactions.

When comparing sources, consider total cost including shipping, warranty terms, and technical support availability. The Check Valve RVP 30 from authorized channels includes documentation, CAD files for system design, and access to HYDAC engineers for application questions. These services add value beyond the component itself.

Economic Considerations

The Check Valve RVP 30 represents a moderate investment within a complete hydraulic system. Typical pricing of 500 to 800 euros positions it as a premium component compared to economy alternatives. This cost is justified by the valve's long service life and zero leakage performance, which reduces fluid waste and prevents contamination.

Return on investment comes primarily from reduced downtime and maintenance costs. Systems using the RVP 30 experience fewer unplanned shutdowns due to valve failure. The metal-to-metal seal eliminates gradual leakage that can contaminate systems and damage downstream components. Over a typical installation life of 5 to 10 years, these savings often exceed the initial price difference versus cheaper check valves.

Energy efficiency also contributes to economic value. The low pressure drop characteristics of the Check Valve RVP 30 mean less pump power is wasted pushing fluid through the valve. In large systems operating continuously, this energy savings can amount to thousands of dollars annually.

Maintenance costs stay low because the RVP 30 uses standard seal kits and requires only basic tools for service. Replacement parts remain available from HYDAC and distributors even for valves installed decades ago. This long-term parts availability protects the investment in equipment and reduces obsolescence risk.

Future Trends and Digital Integration

The hydraulic component industry is gradually incorporating sensors and digital monitoring. While the current Check Valve RVP 30 is a purely mechanical device, future versions may include pressure sensors or flow monitors integrated into the valve body. These additions would enable predictive maintenance by detecting performance degradation before complete failure occurs.

Industry 4.0 initiatives push for greater connectivity between hydraulic components and control systems. A smart version of the RVP 30 could communicate its status to a central monitoring system, alerting operators when maintenance is due or when operating conditions exceed design limits. This development aligns with the broader trend toward condition-based maintenance rather than time-based service intervals.

Despite these technological possibilities, the fundamental design of the Check Valve RVP 30 will likely remain unchanged. The spring-loaded poppet mechanism has proven itself over decades of service across countless applications. Any digital enhancements would supplement rather than replace the core mechanical function.

Making the Right Choice

Selecting the Check Valve RVP 30 depends on matching valve capabilities to system requirements. For applications requiring maximum pressure ratings up to 350 bar and flow rates up to 600 liters per minute, the RVP 30 provides proven performance. The zero leakage seal is critical in systems where even small amounts of reverse flow cause problems.

Budget considerations matter for every project. The Check Valve RVP 30 costs more than basic alternatives but less than electronically controlled valves with similar specifications. This positions it in the middle ground where performance and reliability justify premium pricing without reaching luxury levels.

Technical support and documentation availability favor the RVP 30 for complex systems where integration challenges may arise. HYDAC provides engineering assistance and detailed specifications that help system designers optimize component selection. This support proves valuable when troubleshooting unexpected issues or pushing performance boundaries.

The Check Valve RVP 30 has earned its reputation through consistent performance in demanding applications. Understanding its specifications, proper installation procedures, and maintenance requirements helps users get maximum value from this hydraulic component. Whether protecting expensive pumps, maintaining accumulator pressure, or controlling flow in mobile equipment, the RVP 30 delivers reliable one-way flow control that keeps hydraulic systems operating smoothly.