When you watch a bulldozer lift its blade or see a factory robot move with precision, there's a small but mighty component making it all possible: the directional control valve.

This guide will walk you through everything you need to know about these essential parts, from how they work to choosing the right one for your needs.

What Is a Directional Control Valve?

Think of a directional control valve (DCV) as a traffic controller for fluids. Just like a traffic light directs cars at an intersection, a DCV directs hydraulic oil or compressed air through different paths in a machine. These valves are the "brain" of fluid power systems, telling the fluid where to go and when.

Why Are They Called "Bang-Bang" Valves?

Many DCVs work like a light switch - they're either fully on or fully off. There's no in-between position, which is why people sometimes call them "bang-bang" valves. When they switch, they do it quickly and completely.

How Does a Directional Control Valve Work?

The Basic Parts

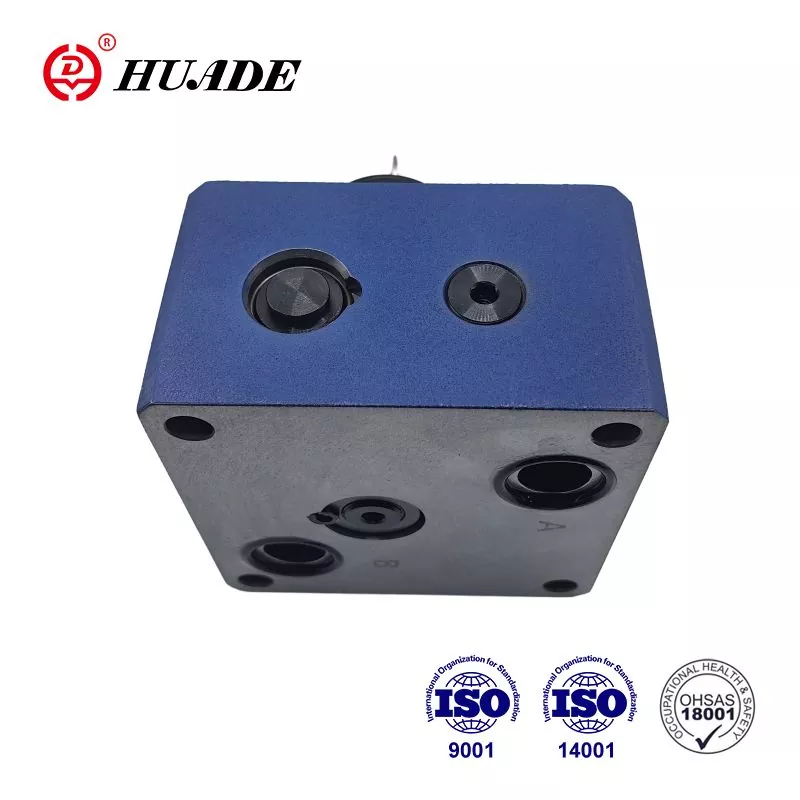

Every DCV has these main components:

Valve Body: This is like the house that holds everything together. It has channels inside where fluid can flow.

Spool or Poppet: This is the moving part that actually controls the flow. Think of it like a sliding door that opens and closes different pathways.

Ports: These are the connection points where pipes attach. They're usually labeled:

- P = Pressure (where fluid comes in)

- T = Tank (where fluid returns)

- A and B = Actuator ports (where fluid goes to do work)

Actuator: This is what moves the spool. It could be a handle you push, an electric coil, or fluid pressure.

How It Controls Flow

When the actuator moves the spool, it lines up different holes and channels inside the valve body. This creates new pathways for fluid to flow through. It's like rearranging puzzle pieces to create different paths.

Types of Directional Control Valves

By How They Move (Internal Design)

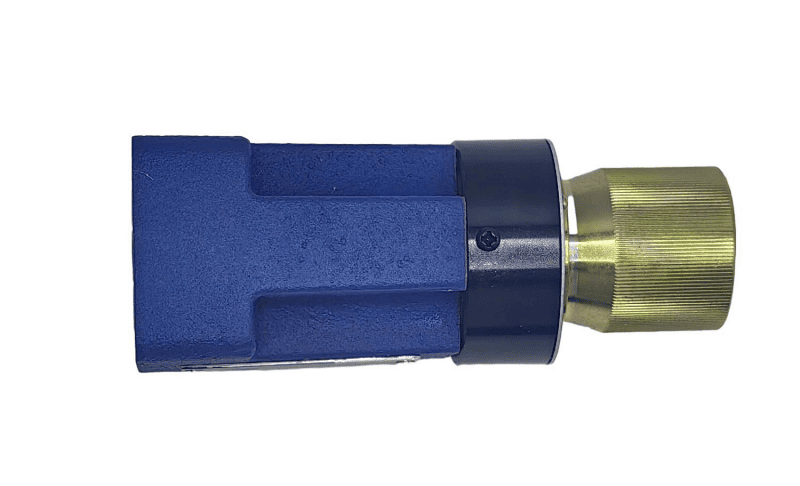

Spool Valves

These use a cylindrical piece (the spool) that slides back and forth. They're like a sliding puzzle where moving one piece opens some paths and closes others. They're versatile but allow a tiny bit of leakage.

Poppet Valves

These use a ball, cone, or disc that lifts off a seat to allow flow or presses down to stop it. Think of a cork in a bottle - when you remove it, liquid flows out. These valves seal very tightly with almost no leakage.

Rotary Valves

Instead of sliding, these rotate to line up different passages. They're like turning a key in a lock to open different doors.

By How They're Operated

Manual Valves

You operate these by hand using a lever, button, or pedal. They're simple and reliable, like a manual car transmission.

Solenoid Valves

These are operated electrically. When you send an electrical signal, a magnetic coil moves the valve. It's like having a remote control for your valve.

Pilot-Operated Valves

These use fluid pressure to move the valve. They're useful when you need a lot of force to move a big valve, like using power steering in a car.

By Number of Positions and Ports

The naming system might seem confusing at first, but it's actually simple:

- 2/2 Valve: 2 ports, 2 positions (like an on/off switch)

- 3/2 Valve: 3 ports, 2 positions (common for single-acting cylinders)

- 4/2 Valve: 4 ports, 2 positions (standard for double-acting cylinders)

- 4/3 Valve: 4 ports, 3 positions (includes a neutral middle position)

Center Positions (For 3-Position Valves)

- Open Center: All ports connect together - like opening all the doors in a house

- Closed Center: All ports are blocked - like closing all the doors

- Tandem Center: Pressure connects to tank, but actuator ports are blocked

- Float Center: Actuator ports connect to tank, but pressure is blocked

Choosing the Right Valve: Key Specifications

Flow Rating (Cv)

This tells you how much fluid the valve can handle. It's measured as gallons per minute (GPM) at 1 PSI pressure drop. Think of it like the diameter of a garden hose - bigger numbers mean more flow capacity.

Pressure Rating

This is the maximum pressure the valve can handle safely. It's usually marked as PN (like PN350 for 350 bar) or in PSI. Don't exceed this limit, or the valve could fail.

Response Time

For solenoid valves, this is how fast they can switch positions, usually measured in milliseconds. Faster response times are better for applications that need quick movements.

Leakage Class

This rates how well the valve seals:

- Class IV: Some leakage (0.01% of rated flow)

- Class V: Low leakage

- Class VI: Bubble-tight (almost no leakage)

From Simple to Smart: Types of Control

On/Off Valves (Standard DCVs)

These are the basic "bang-bang" valves we talked about. They're either fully open or fully closed. They're perfect for simple tasks like clamping a part or extending a cylinder completely.

Proportional Valves

These are like dimmer switches for fluid flow. Instead of just on/off, they can be partially open to control flow rate. This gives you smooth, variable speed control. They're great for applications like crane operation where you want smooth movements.

Servo Valves

These are the precision instruments of the valve world. They provide extremely accurate control and can respond to feedback to maintain exact positions or flows. They're used in high-end applications like flight simulators and CNC machines.

Real-World Applications

Construction Equipment

- Excavators: Use multiple 4/3 valves to control the boom, arm, bucket, and rotation. Pilot-operated proportional valves give the operator smooth control.

- Bulldozers: Use DCVs to control blade angle and height, as well as track drive systems.

Manufacturing

- CNC Machines: Use solenoid DCVs for tool clamping and proportional valves for precise positioning.

- Assembly Lines: Pneumatic DCVs operate grippers, lifters, and sorting mechanisms.

Agriculture

- Tractors: Multi-spool valve blocks control implements like plows and mowers.

- Harvesters: DCVs control header height and cleaning fan speed.

Aerospace

- Aircraft Landing Gear: Servo valves provide precise, reliable control for extension and retraction.

- Flight Controls: High-performance servo valves enable fly-by-wire systems.

Market Overview: Who Makes What

The global directional control valve market is worth about $8-10 billion and growing at 5-11% per year. Key players include:

- Bosch Rexroth: Known for robust hydraulic valves and Industry 4.0 integration

- Parker Hannifin: Offers broad ranges for both hydraulic and pneumatic applications

- Eaton/Danfoss: Strong in mobile hydraulics with smart valve technologies

- SMC: Leading pneumatic valve manufacturer with compact, high-flow designs

- Festo: Innovative pneumatic solutions including valve islands and digital platforms

- Moog: High-precision servo valves for demanding applications

The Future: Smart Valves and Industry 4.0

Smart Features

Modern valves are getting smarter with built-in sensors that monitor:

- Temperature

- Number of cycles

- Position feedback

- Flow rates

- Contamination levels

Digital Integration

New valves can communicate using protocols like:

- IO-Link

- EtherNet/IP

- Profibus

- Modbus

This allows them to send diagnostic data to central control systems, enabling predictive maintenance.

Predictive Maintenance

Instead of waiting for valves to fail, smart systems can predict when maintenance is needed based on real-time data. This reduces unexpected downtime and saves money.

Troubleshooting Common Problems

Valve Won't Actuate

Possible Causes: No electrical signal, burned coil, low pilot pressure

Solutions: Check voltage, test manual override, verify pilot air/oil supply

Slow or Jerky Movement

Possible Causes: Internal leakage, contaminated fluid, wrong valve size

Solutions: Test for leakage, change fluid and filters, verify valve sizing

Actuator Drifts

Possible Causes: Wrong center position, worn spool, external leakage

Solutions: Check valve configuration, test for internal wear, inspect connections

External Leakage

Possible Causes: Worn seals, loose bolts, cracked body

Solutions: Replace seals, check bolt torque, inspect for damage

Noise or Overheating

Possible Causes: Cavitation, valve too small, pressure too high

Solutions: Check fluid level, verify valve sizing, adjust relief valve setting

Maintenance Best Practices

Regular Inspections

- Check for external leaks

- Look for corrosion or damage

- Verify all connections are tight

- Test manual overrides

Fluid Maintenance

- Sample fluid regularly for contamination

- Change filters on schedule

- Keep system temperature under 140°F (60°C)

- Maintain proper fluid levels

Preventive Actions

- Cycle valves periodically to prevent sticking

- Keep spare parts inventory

- Train operators on proper use

- Document maintenance history

Making the Right Choice

When selecting a directional control valve, consider these factors:

Function Needed: How many ports and positions do you need?

Pressure and Flow: What are your system requirements?

Fluid Type: Hydraulic oil, air, water, or specialty fluids?

Control Method: Manual, electric, or pilot operation?

Environment: Temperature, dust, hazardous areas?

Budget: Initial cost vs. long-term reliability

Conclusion

Directional control valves are the unsung heroes of modern machinery. From the excavator at a construction site to the robot on an assembly line, these valves make controlled motion possible. As technology advances, valves are becoming smarter and more integrated with digital systems, but their fundamental job remains the same: controlling the flow of fluid to create useful work.

Whether you're designing a new system, troubleshooting an existing one, or simply trying to understand how things work, understanding directional control valves opens the door to comprehending the fluid power systems that surround us every day.

The key to success with DCVs is matching the right valve type to your specific application needs, maintaining them properly, and staying current with evolving technologies. With this foundation, you'll be well-equipped to make informed decisions about these critical components.