Take Care of Your Fluid

- Use the exact fluid your manufacturer recommends

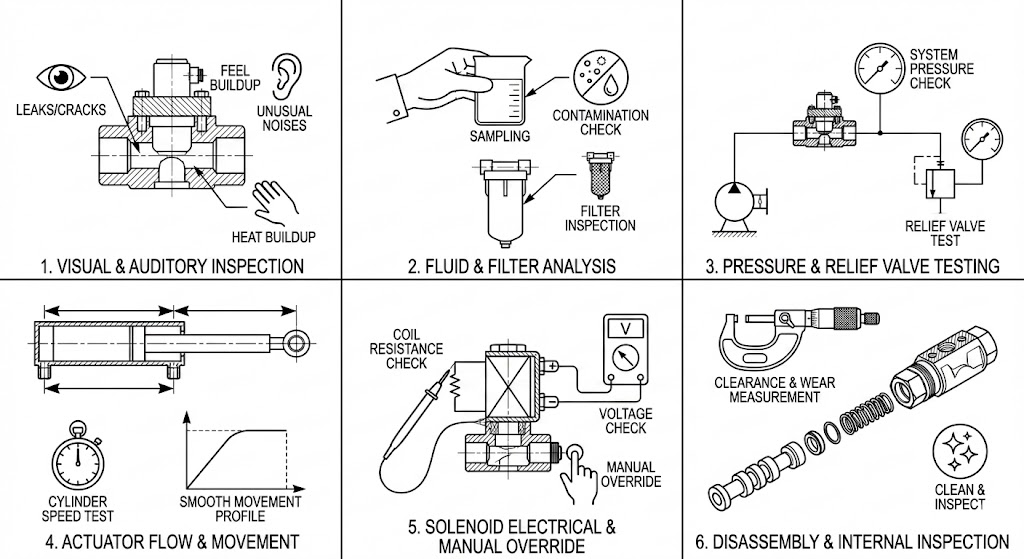

- Test fluid quality regularly

- Change filters based on pressure drop, not just time

- Clean your reservoir once a year

Regular Inspections

- Check for leaks every month

- Look for wear, corrosion, or damage

- Clean valve parts when they get dirty

- Keep detailed records of what you find

Proper Adjustments

- Follow manufacturer settings exactly

- Check relief valve settings regularly

- Make sure everything is calibrated correctly

- Get professional help for complex adjustments

Replace Parts Before They Fail

- Change seals and hoses based on usage hours

- Fix small problems before they become big ones

- Keep spare parts on hand for critical valves

- Plan maintenance during scheduled downtime

Train Your Team

- Make sure everyone knows how to operate equipment properly

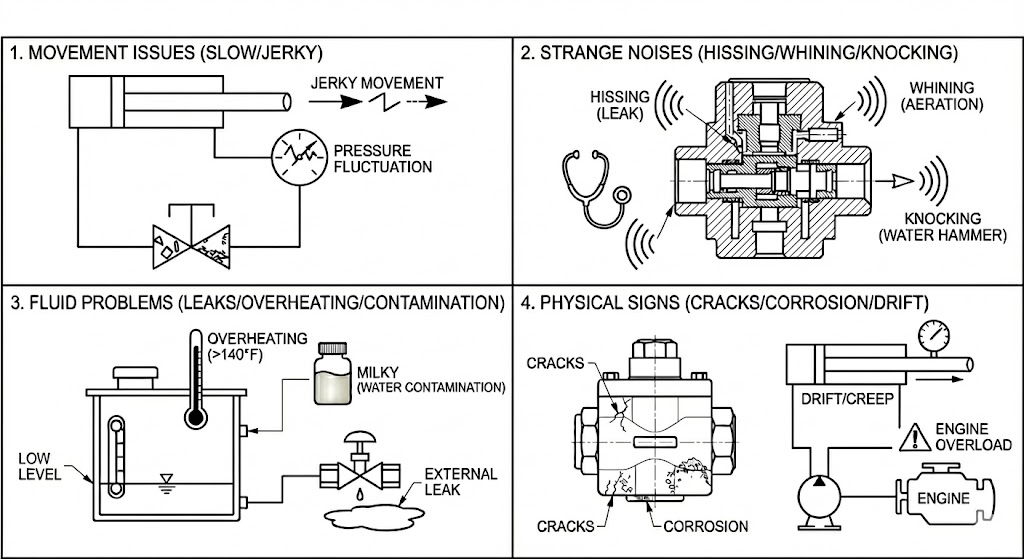

- Teach people to recognize warning signs

- Document problems and solutions

- Share knowledge across your team