When working with hydraulic systems, controlling fluid flow in both directions becomes critical for safety and performance. The pilot operated check valve SV serves this exact purpose by allowing free flow in one direction while blocking reverse flow until commanded to open. This smart valve design has become essential in modern hydraulic applications where load holding and controlled release are necessary.

The pilot operated check valve SV differs from standard check valves through its unique control mechanism. While traditional check valves simply prevent backflow, the SV version adds a pilot control port that can override the blocking function when needed. This seemingly simple addition transforms the valve from a passive component into an active control element.

Understanding the Basic Design

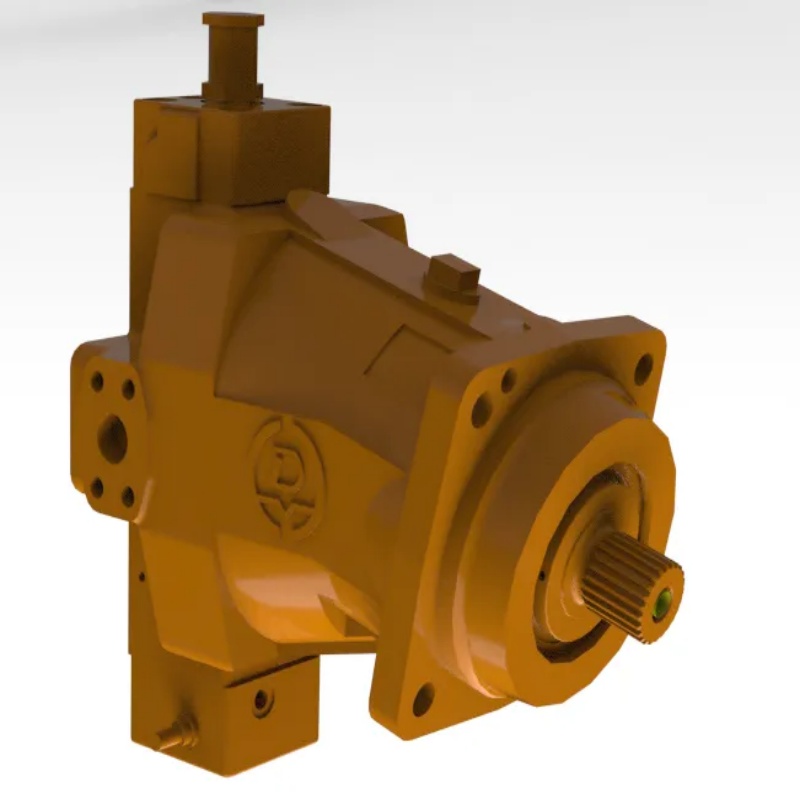

The pilot operated check valve SV consists of several key components working together. The main poppet valve handles the primary flow path from port A to port B. When fluid flows in this direction, pressure pushes the poppet open against a light spring, allowing nearly unrestricted passage. The pressure drop typically measures around 4 bar at 100 liters per minute for a standard NG10 size valve.

The reverse direction tells a different story. When pressure builds at port B trying to flow back toward port A, the poppet seats firmly against its sealing surface. The system pressure actually helps create this seal, with the compressed spring adding extra force. This design achieves leakage rates below 0.1 milliliters per minute even at maximum working pressure of 315 bar.

The pilot control mechanism uses port X to override the blocking function. When pilot pressure reaches the control piston, it generates sufficient force to push the main poppet off its seat despite the opposing load pressure. The required pilot pressure typically runs about 5 bar above the load pressure for reliable opening.

How Pressure Areas Determine Performance

The effectiveness of a pilot operated check valve SV depends heavily on the relationship between different pressure areas within the valve. Engineers designate these areas as A1 through A4, each serving a specific purpose in the force balance equation.

Area A1 represents the main poppet face exposed to load pressure. For a size 10 valve, this measures approximately 1.33 square centimeters. Area A2 shows the pilot poppet surface, typically one quarter the size of A1. The control piston area A3 must be large enough to overcome the combined forces from load pressure and spring tension, usually ranging from 2 to 3.8 square centimeters for smaller valves.

The force balance determines when the valve opens. Load pressure multiplied by the effective area difference between A1 and A2, plus spring force, must be overcome by pilot pressure acting on area A3. This mathematical relationship ensures predictable operation across varying load conditions.

Two Main Configuration Types

Pilot operated check valves come in SV and SL configurations, each suited to different circuit requirements. The SV type features internal drain routing where the pilot chamber vents back to port A. This compact design works well when port A connects to tank or low pressure, keeping the installation simple and minimizing external connections.

The SL configuration adds a separate external drain port Y. This arrangement proves necessary when port A carries significant pressure that would interfere with pilot operation. By routing control chamber drainage independently, the valve operates reliably even with preloaded or pressurized A ports. The annular area A4, smaller than A3, determines the effective control area in SL valves.

Choosing between SV and SL depends on your circuit design. If port A remains near atmospheric pressure, the simpler SV version usually suffices. When port A sees substantial pressure or connects to another pressurized component, the SL configuration prevents unwanted pilot interference.

The Decompression Feature

Standard pilot operated check valves can create significant pressure spikes when opening under high load. The sudden release of trapped pressure generates hydraulic shock that stresses components and creates noise. To address this issue, manufacturers developed the A-type decompression variant.

The decompression mechanism incorporates a small ball valve that opens slightly before the main poppet. This allows controlled pressure reduction in the control volume, typically limiting pressure drop to under 50 bar. For a size 10 valve, the control volume measures about 2.5 cubic centimeters, which must decompress before full opening occurs.

The decompression process adds a brief delay to valve response but significantly reduces system stress. Applications involving large cylinders or high inertia loads particularly benefit from this feature. The trade-off between response time and smooth operation requires careful consideration during system design.

Size Ranges and Flow Capacity

The pilot operated check valve SV series spans from size 06 through 32, following ISO 5781 standards. Each size designation roughly corresponds to the nominal port diameter in millimeters divided by approximately 1.6. This standardization helps engineers quickly estimate valve capacity and mounting requirements.

Size 06 and 10 valves handle flows up to 150 liters per minute, weighing between 0.8 and 1.8 kilograms. These compact units fit tight spaces while providing reliable load holding for small to medium cylinders. The modest control volume of 1.2 to 2.5 cubic centimeters allows quick response times.

Medium sizes 16 and 20 accommodate flows from 150 to 300 liters per minute. Physical dimensions increase accordingly, with size 20 valves weighing around 7.8 kilograms. The larger control volumes of 5 to 10.8 cubic centimeters require more pilot oil but handle proportionally larger flow forces.

Size 25 and 32 valves serve heavy-duty applications with flow capacities reaching 550 liters per minute. These substantial valves weigh 8 to 12 kilograms and demand robust mounting. Control volumes of 12 to 19.27 cubic centimeters ensure adequate pilot force even against maximum load pressure.

Installation Considerations

Proper mounting ensures long service life and reliable operation. The pilot operated check valve SV typically mounts to a subplate following ISO 5781 interface standards. The mounting surface requires a maximum roughness of 1 micrometer to prevent leakage paths around the sealing gasket.

Mounting bolts must be torqued correctly to achieve proper sealing without distorting the valve body. Standard specifications call for 75 newton-meters with a friction coefficient of 0.14. Size 10 valves use four M10 bolts of 50 millimeter length, while size 32 requires six M10 bolts at 85 millimeters long. Uneven torque distribution can warp the mounting surface and compromise seal integrity.

The orientation generally doesn't matter for pilot operated check valves since they rely on pressure forces rather than gravity. However, mounting position should allow easy access to adjustment features if present. Consider the location of pilot and drain ports when planning piping connections to minimize external line routing.

Hydraulic Fluid Requirements

The pilot operated check valve SV functions reliably with standard mineral-based hydraulic oils meeting HL or HLP specifications. Operating viscosity ranges from 2.8 to 500 square millimeters per second, though optimal performance occurs between 16 and 46 centistokes at 40 degrees Celsius. Lower viscosity reduces pressure drop but may increase leakage, while higher viscosity does the opposite.

Temperature limits depend on seal materials. Standard nitrile rubber seals tolerate minus 30 to plus 80 degrees Celsius, suitable for most industrial environments. Applications involving high temperatures or synthetic fluids benefit from fluorocarbon seals, which handle minus 20 to plus 80 degrees while resisting aggressive media. Biodegradable fluids like HETG often require fluorocarbon seals as well.

Fluid cleanliness directly impacts valve life and reliability. The recommended contamination level of ISO 4406 20/18/15 means no more than 5000 particles per milliliter above 4 micrometers, 1300 above 6 micrometers, and 320 above 14 micrometers. Proper filtration per Bosch Rexroth standard RE 50070 maintains these limits and prevents premature wear.

Common Application Scenarios

Construction equipment represents one of the largest markets for pilot operated check valves. Excavator boom cylinders require reliable load holding to prevent arm drop when the operator releases controls. A pilot operated check valve SV installed in each cylinder port provides this safety function. When the operator actuates the control lever, pilot pressure from the directional valve opens the check valves, allowing controlled lowering.

Injection molding machines use these valves to secure mold clamping cylinders. The tremendous forces involved, often exceeding 100 kilonewtons, demand zero-leakage load holding. Two pilot operated check valves in a redundant configuration meet safety category 3 per EN ISO 13849 standards. If one valve fails, the second maintains load support until maintenance can address the issue.

Lifting equipment applications combine pilot operated check valves with flow control valves for smooth load descent. The check valve prevents uncontrolled dropping while a separate throttle valve meters the release rate. This arrangement satisfies ANSI B30.5 requirements for crane and hoist safety systems. The pilot signal comes from the operator's control valve, ensuring conscious action precedes any lowering motion.

Performance Characteristics

The pressure drop through a pilot operated check valve SV in the free flow direction varies with size and flow rate. A size 32 valve passing 400 liters per minute typically shows approximately 20 bar of pressure loss. This relatively low resistance makes the valve efficient during normal operation when frequently cycling loads up and down.

The pilot pressure ratio determines control characteristics. For valves without decompression, the pilot pressure must equal load pressure plus 2 to 5 bar to guarantee opening. Decompression versions show more variation, with a scatter band of plus or minus 10 bar depending on flow rate and valve condition. This variation reflects the staged opening process as the ball valve bleeds pressure before the main poppet moves.

Response time matters in applications requiring quick load release. The time lag between applying pilot pressure and achieving full flow depends on control volume and pilot flow capacity. Smaller valves respond in under 50 milliseconds, while larger units may require 100 to 200 milliseconds. Adding decompression increases these times slightly but remains acceptable for most industrial uses.

Cracking Pressure Options

The spring preload in a pilot operated check valve SV determines its cracking pressure in the free flow direction. Manufacturers typically offer four standard options: 1.5, 3, 6, and 10 bar for smaller sizes, or 2.5, 5, 7.5, and 10 bar for larger valves. This adjustable feature allows matching the valve to specific circuit requirements.

Lower cracking pressures minimize energy loss during normal operation but may allow slight back-leakage under high load. Applications prioritizing efficiency over absolute sealing performance often specify 1.5 or 2.5 bar settings. The reduced spring force also means less pilot pressure is needed to open the valve in reverse.

Higher cracking pressures improve sealing under extreme conditions and prevent unintended opening from pressure fluctuations. Heavy construction equipment and safety-critical applications frequently use 6 or 10 bar settings. The stronger spring force provides additional security against seal failure but increases both forward pressure drop and required pilot pressure.

Comparing to Alternative Valve Types

Simple check valves cost significantly less than pilot operated versions but lack reverse opening capability. Their leakage rates of 5 to 10 milliliters per minute under load prove unacceptable for applications requiring long-term position holding. The pilot operated check valve SV improves leakage performance by a factor of fifty while adding controlled release functionality.

Counterbalance valves offer similar load holding with integrated pressure relief and flow control. These valves work well for overrunning loads like vertical cylinders where gravity assists motion. However, they typically cost more than pilot operated check valves and introduce additional pressure drop in both directions. The pilot operated check valve SV excels when free flow in one direction is important.

Double pilot operated check valves provide redundant load holding for safety-critical applications. Each valve can independently support the full load, meeting higher safety categories. The increased cost and complexity only make sense where regulations or risk assessment demands redundancy. Single pilot operated check valves suffice for most industrial applications when properly sized and maintained.

Sizing and Selection Process

Determining the correct pilot operated check valve SV size begins with flow requirements. Calculate the maximum flow rate through the valve in both directions, including any simultaneous operations. Select a valve size that handles this flow with acceptable pressure drop, typically under 20 bar for the free flow direction.

Verify that working pressure stays within the valve's 315 bar maximum rating. Include safety factors and consider pressure spikes from rapid valve closure or pump deadheading. The pilot pressure source must reliably deliver at least 5 bar above maximum load pressure to ensure consistent opening performance.

Choose between SV and SL configurations based on port A conditions. If this port connects to tank or remains unpressurized, the simpler SV design works well. When port A carries significant pressure or feeds other components, specify the SL version with external drain. Route the Y port to tank through adequately sized piping.

Decide whether decompression is necessary by evaluating potential pressure shock. Systems with large trapped volumes or sensitive components benefit from the A-type version. The slight response delay rarely causes problems in typical industrial cycles. Standard versions without decompression cost less and respond faster for applications where shock loading isn't a concern.

Reading Ordering Codes

Manufacturers use systematic designation codes to specify pilot operated check valve configurations. A typical code like SV 10 PA1-4X breaks down into distinct elements. The first letters indicate valve type, SV for internal drain or SL for external. The number following shows the size designation, in this case 10.

The next position reveals mounting style, with P indicating subplate and G meaning threaded ports. The letter A appears when decompression is included, otherwise this position is blank. The number represents cracking pressure selection from 1 through 4, corresponding to increasing spring preload options.

The suffix 4X identifies the current series generation, indicating design improvements and updated specifications. A trailing slash often precedes additional options like seal material, with V designating fluorocarbon instead of standard nitrile. Understanding these codes helps communicate requirements precisely with suppliers and ensures receiving the correct configuration.

Maintenance Requirements

Regular inspection keeps pilot operated check valves functioning reliably. Every 5000 operating hours, check hydraulic fluid contamination levels and replace filter elements if cleanliness exceeds ISO 4406 20/18/15. Degraded fluid quality accelerates seal wear and allows abrasive particles to damage seating surfaces.

External leakage around the valve body usually indicates seal degradation requiring replacement. Internal leakage shows as gradual load drift when the valve should hold position. Remove and disassemble the valve to inspect the poppet seating surface for wear or contamination embedment. Light polishing can restore sealing on minor damage, but deep scoring requires poppet replacement.

Pilot control issues manifest as sluggish opening or failure to release loads. Verify adequate pilot pressure reaches port X using a pressure gauge during operation. Low pressure may result from undersized pilot lines, excessive length, or restrictions. Inspect the pilot poppet and control piston for contamination or damage that could cause binding.

Troubleshooting Common Problems

When a pilot operated check valve SV leaks in the blocking direction, several causes deserve investigation. Contamination particles lodged between the poppet and seat prevent complete closure. Flushing the system with clean oil sometimes dislodges debris, but disassembly and thorough cleaning may be necessary. Verify fluid filtration meets specifications to prevent recurrence.

Poppet seat wear from repeated impact or cavitation damage creates leakage paths that cleaning cannot fix. Examine the seating surfaces during maintenance for signs of erosion or mechanical damage. Seat replacement components are available for most valves, though extensive damage may require complete valve replacement. Installing decompression-type valves reduces impact forces that cause premature wear.

Valves that won't open despite adequate pilot pressure often suffer from contamination binding the control piston. Sludge formation from fluid degradation or ingested dirt can restrict piston movement. Complete disassembly with solvent cleaning usually restores function. Consider improving fluid filtration and shortening change intervals to prevent contamination buildup.

Safety Considerations

The pilot operated check valve SV serves critical safety functions in many applications. Failure could result in uncontrolled load descent, equipment damage, or operator injury. Safety-critical circuits should incorporate redundant valves or backup systems per applicable standards like EN ISO 13849 for machinery safety.

Regular functional testing verifies proper operation under actual load conditions. This involves cycling the load while monitoring for drift or unexpected movement. Document test results and investigate any anomalies before returning equipment to service. Replace valves showing degraded performance before complete failure occurs.

Pilot pressure loss presents a significant hazard since it could allow unintended load release. Design circuits to ensure pilot pressure remains available during all normal operations. Consider using separate pilot pressure sources independent of the main system for added reliability. Install pressure switches to alert operators when pilot pressure falls below safe minimums.

Economic Considerations

The pilot operated check valve SV costs approximately two to three times more than simple check valves but delivers substantially better performance. This price premium buys precise control, minimal leakage, and extended service life. For applications requiring reliable load holding, the increased cost represents sound investment compared to alternatives.

Larger valve sizes show greater price differences. A size 32 valve with decompression and external drain can exceed ten times the cost of a basic same-size check valve. However, the pilot operated design may eliminate the need for additional components like counterbalance valves or separate locking mechanisms. Evaluate total system cost rather than individual component prices.

Energy efficiency impacts operating costs over the valve's lifetime. The low pressure drop in free flow direction reduces power consumption compared to many alternatives. A 5 bar reduction in system pressure at 100 liters per minute saves approximately 100 watts continuously. These savings accumulate substantially in frequently cycling applications.

Environmental Adaptability

Modern pilot operated check valves accommodate biodegradable hydraulic fluids gaining popularity for environmental protection. Fluids meeting HETG specifications (vegetable oil-based) require fluorocarbon seals instead of standard nitrile. This compatibility allows environmentally conscious operations without sacrificing performance or reliability.

Temperature extremes affect valve operation through fluid viscosity changes and seal material properties. Cold environments increase viscosity, raising pressure drops and potentially slowing response. Fluorocarbon seals tolerate lower temperatures better than nitrile for cold-weather applications. High temperatures reduce viscosity and accelerate seal degradation, demanding shorter service intervals.

Corrosive environments may require special surface treatments beyond standard zinc plating. Marine applications often specify additional corrosion protection through hard anodizing or specialized coatings. Discuss environmental conditions with manufacturers when selecting valves for harsh service to ensure adequate protection and expected life.

Future Developments

Sensor integration represents an emerging trend for pilot operated check valves. Built-in pressure transducers could monitor load pressure, pilot pressure, and leakage in real-time. This data enables predictive maintenance by identifying degradation before complete failure. Wireless connectivity would allow remote monitoring of critical valves throughout large installations.

Smart valves with embedded microprocessors might adjust characteristics automatically based on operating conditions. Variable cracking pressure adapted to load weight could optimize efficiency while maintaining safety. Self-diagnostic capabilities would alert maintenance personnel to developing problems and guide troubleshooting procedures.

Materials science advances promise improved sealing performance and extended service life. New polymer compounds offer better wear resistance and broader chemical compatibility. Specialized coatings reduce friction and prevent particle adhesion. These developments will enhance reliability while potentially reducing valve size for given flow capacities.

Conclusion

The pilot operated check valve SV provides essential control for hydraulic systems requiring reliable load holding and controlled release. Its unique design combines the blocking capability of check valves with the controllability of directional valves. Understanding the operating principles, proper sizing, and maintenance requirements ensures successful application.

Selecting the appropriate configuration demands careful analysis of system requirements including flow rate, pressure levels, and circuit design. The choice between standard SV and external drain SL versions depends on port A conditions. Decompression features benefit applications sensitive to pressure shock. Material options accommodate various fluids and environmental conditions.

Regular maintenance and inspection preserve performance throughout the valve's service life. Monitoring fluid quality, checking for leakage, and verifying pilot function catch problems early. Safety-critical applications demand particular attention to testing and documentation. With proper application and care, pilot operated check valves deliver years of reliable service protecting equipment and personnel.