A water flow control valve is a mechanical device installed in pipelines to regulate fluid flow rate by adjusting the opening of the flow passage. In industrial water systems, municipal supply networks, and building services, these valves function as the final control elements that translate control signals into physical changes in flow parameters. When a valve restricts flow, it creates a pressure drop that directly correlates with the flow rate reduction, following the fundamental hydraulic principle where pressure loss increases proportionally with velocity squared.

Core Functions and Operating Principles

Water flow control valves serve three primary functions in hydraulic systems: regulating flow rate via variable resistance, maintaining system pressure, and enabling automated control.

The valve's ability to control flow depends on its flow coefficient ($C_v$), representing the flow rate in US gallons per minute of water at 60°F that produces a 1 psi pressure drop. The mathematical relationship follows:

$$ C_v = Q \sqrt{\frac{SG}{\Delta P}} $$Where $Q$ is flow rate in GPM, $SG$ is specific gravity (water = 1.0), and $\Delta P$ is pressure drop in psi. For metric calculations ($K_v$), the conversion factor is $C_v \approx 1.156 \times K_v$. Mixing unit systems can lead to sizing errors of 15-20%.

Main Types of Water Flow Control Valves

Globe Valves for Precision ControlGlobe valves represent the industry standard for throttling. The internal Z-shaped flow path dissipates energy effectively, making them excellent for high pressure drop applications. Linear plugs provide proportional flow relationships, while equal percentage plugs compensate for non-linear heat transfer in HVAC systems.

Ball Valves for Quick ShutoffBall valves use a spherical closure element. Standard designs are for isolation, but V-port ball valves incorporate a V-shaped cutout enabling throttling with rangeability up to 300:1. They excel in slurry service where particulates would damage conventional seats.

Butterfly and Gate ValvesButterfly valves offer economical solutions for large diameters (>DN150) but perform best for coarse adjustment. Gate valves are strictly for full-bore isolation; throttling with them causes severe vibration and seat erosion.

| Valve Type | Motion | Function | Pressure Drop | Best Applications |

|---|---|---|---|---|

| Globe | Linear | Throttling | High | Steam control, precise regulation |

| Gate | Linear | Isolation | Very Low | Main line shutoff, pump isolation |

| Ball | Rotary (90°) | Shutoff / V-port Throttling | Low | Quick isolation, slurry service |

| Butterfly | Rotary (90°) | Shutoff / Coarse control | Medium | Large water mains, HVAC |

Material Selection for Water Service

Water chemistry (chlorine, pH, dissolved oxygen) drives corrosion mechanisms.

-

Brass/Bronze: Used in small valves (

- Cast Iron: Backbone of municipal infrastructure. Requires Fusion-Bonded Epoxy (FBE) coatings to prevent rusting.

- Stainless Steel (316/Duplex): Essential for corrosive conditions. 316 SS handles chlorides >200 mg/L. Super Duplex is required for seawater (PREN > 40).

Actuator Systems and Control Integration

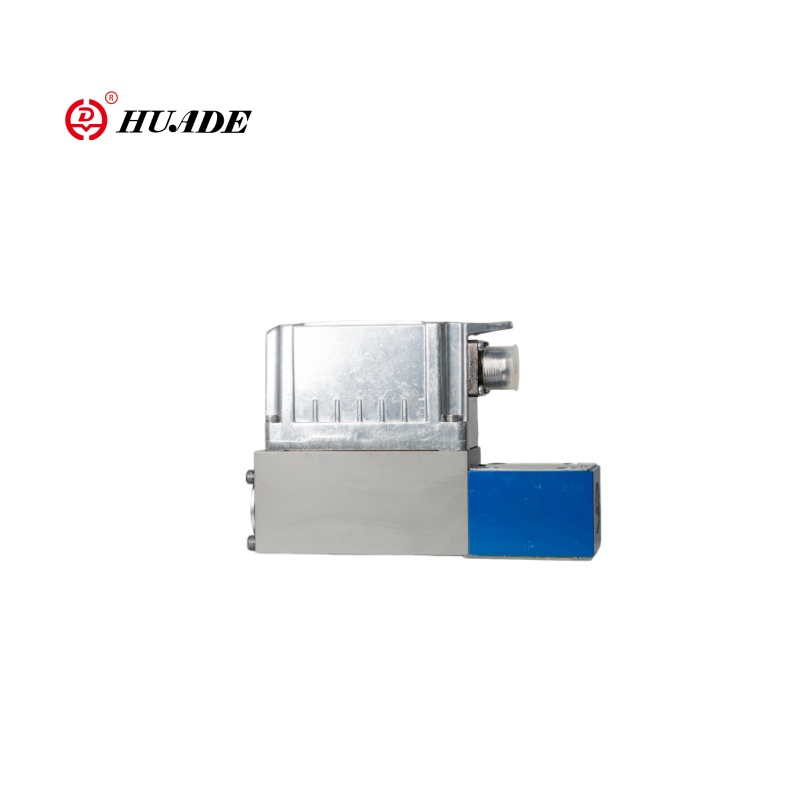

Pneumatic Actuators: Dominate process control due to speed (1-3s stroke) and inherent fail-safe capabilities (spring-return).

Electric Actuators: Offer precise positioning (0.1-1%) but are slower (15-60s) and require battery backups for fail-safe operation.

Smart Positioners: Digital devices that enable condition-based maintenance by monitoring valve friction and deadband.

Cavitation and Flashing Phenomena

Pressure drop can cause water to vaporize, creating severe damage. Flashing occurs when downstream pressure remains below vapor pressure, causing sonic velocity flow. Cavitation occurs when bubbles form and then violently collapse as pressure recovers, generating shockwaves that erode steel.

The cavitation index ($\sigma$) quantifies risk: $$ \sigma = \frac{P_2 - P_v}{P_1 - P_2} $$ When $\sigma$ falls below critical values (1.5-3.0), cavitation is likely. Multi-stage trim designs prevent this by breaking large pressure drops into smaller, safe steps.

Critical Application: Pressure Independent Control Valves (PICV)

PICVs solve the problem of hydraulic interaction in variable flow HVAC systems. They integrate a differential pressure regulator and a flow control valve in one body.

100% Valve Authority: The internal regulator maintains constant differential pressure across the control element. Flow depends only on stem position, regardless of system pressure fluctuations.

Energy Savings: Eliminates overflow in low-load zones, typically reducing pumping energy by 20-30% compared to traditional balancing.

Sizing and Maintenance

Sizing: Use the $C_v$ formula. A valve operating at 70-80% open during normal conditions is ideal. Divide required $C_v$ by 0.75 for proper sizing.

Valve Authority ($N$): Should be between 0.3 and 0.5. Low authority (<0.25) turns a modulating valve into an on/off switch.

Valve signature analysis monitors stem friction and response time. Increasing friction suggests packing issues; deadband growth indicates linkage wear.

| Component | Material | Expected Life | Maintenance Indicator |

|---|---|---|---|

| Valve Body | Ductile Iron | 40-50 years | External corrosion |

| Trim | 316 SS | 10-15 years | Increasing leakage |

| Packing | Graphite | 3-5 years | Stem leakage |

| Actuator Diaphragm | Nitrile | 5-8 years | Loss of fail-safe force |

Future Outlook: The convergence of hydraulic engineering with digital twins and AI is transforming valves from simple mechanical devices into intelligent network nodes, enabling self-optimizing water distribution systems.