When hydraulic systems need reliable flow control without leakage, the check valve sandwich plate Z2S 22 stands out as a proven solution. This Bosch Rexroth component has been supporting industrial equipment for years, and understanding how it works can help you make better decisions for your hydraulic setup.

What Makes the Z2S 22 Different

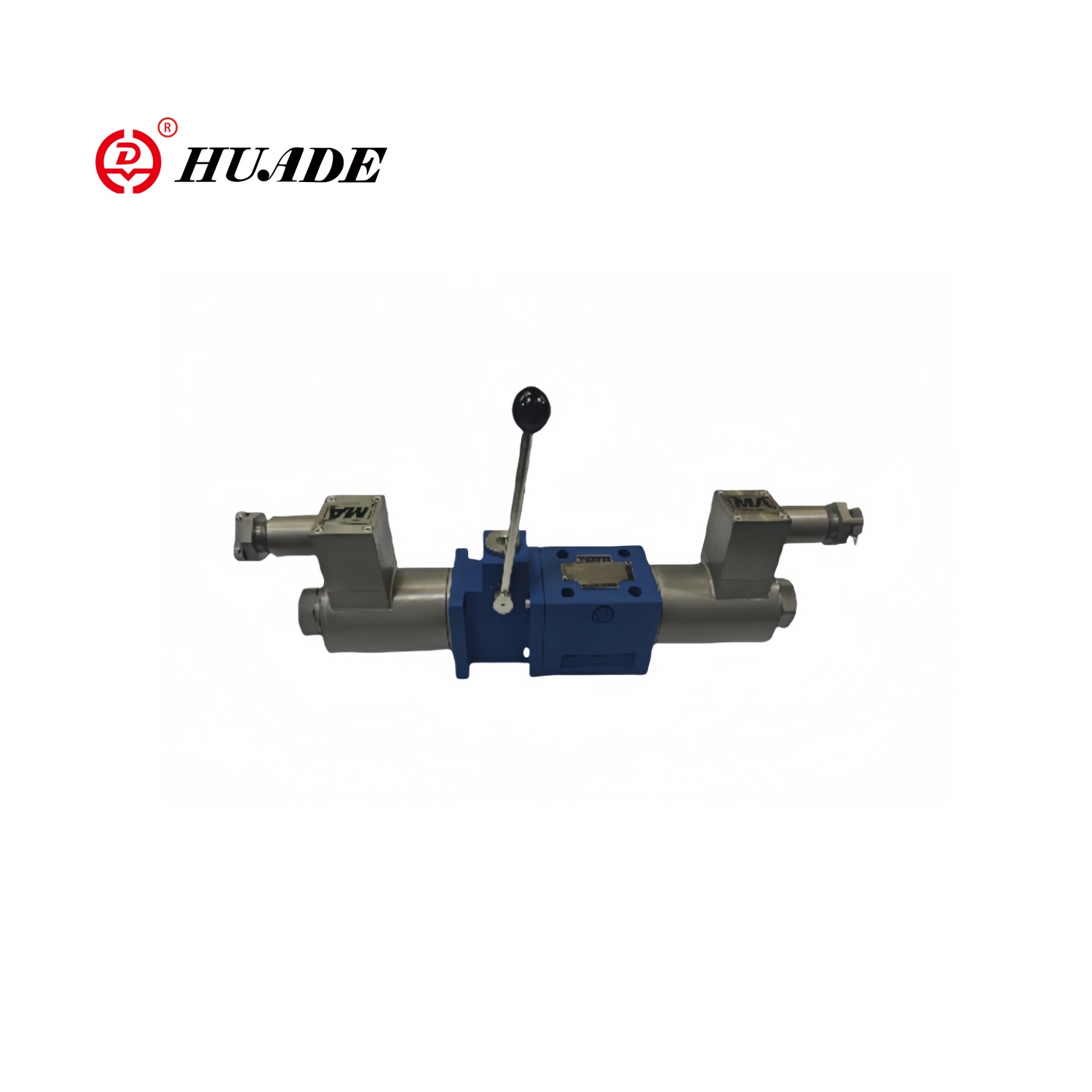

The Z2S 22 check valve sandwich plate operates as a pilot-operated check valve designed for NG25 size systems. Unlike basic spring-loaded check valves, this sandwich plate uses a two-stage design that provides better control when releasing pressure. The valve allows free flow in one direction while blocking reverse flow, and it can be opened from the blocked side when pilot pressure is applied to the X port.

The sandwich plate design means you can stack it vertically between other hydraulic components. This saves space in crowded machine installations. The Z2S 22 follows ISO 4401-08-08-0-05 port patterns, making it compatible with standard hydraulic manifolds used across different equipment types.

What sets this check valve apart is the pre-opening feature in most versions. When the pilot valve opens, the pressure releases gradually through a dampening system instead of all at once. This prevents the shock waves and noise that damage seals and create maintenance headaches in hydraulic systems.

Technical Specifications That Matter

The Z2S 22 check valve sandwich plate handles maximum working pressure up to 315 bar and flow rates reaching 450 liters per minute. These numbers come from tests using HLP46 mineral oil at 40 degrees Celsius. The valve body weighs between 12 and 13 kilograms, with dimensions of 212mm length, 117mm width, and 100mm height.

Cracking pressure options range from 3 bar to 10 bar, marked by codes 1 through 4 in the part number. Higher cracking pressure means stronger reverse blocking but requires more pilot pressure to open. The valve works with hydraulic oil temperatures from negative 30 to positive 80 degrees Celsius when using NBR seals, which covers most industrial environments.

Port connections include P, A, B, T, X, and Y positions. The A and B ports connect to actuators, while the X port receives pilot pressure to release the check function. Installation requires six M12 bolts torqued to 70 Nm, and the mounting surface needs a roughness rating of Rz 4 or smoother to prevent leaks.

The check valve sandwich plate Z2S 22 maintains zero leakage in the blocking direction during normal operation. This matters for applications like holding vertical cylinders in position overnight or during maintenance stops. Even after months of downtime, the valve should maintain its seal without drift.

How the Z2S 22 Actually Works

Flow moves freely from A1 to A2 or B1 to B2 through the valve when pressure pushes in the open direction. A simple flap valve opens under flow pressure, creating minimal resistance. Pressure drop curves show nearly linear behavior, meaning flow increases predictably as pressure rises.

In the reverse direction, the flap valve seats firmly against the valve body, creating the blocking seal. The valve uses a ball seat design with area A2 and a poppet with area A1. When pilot pressure enters through port X, it acts on control spool area A3. The area ratio between A3 and A2 runs about 1 to 12.5, which means you need relatively low pilot pressure to open the main valve.

The pre-opening mechanism starts working before full pilot pressure arrives. As the control spool begins moving, a small opening appears that lets pressure equalize gradually. This cushioned opening prevents the sudden pressure drop that causes water hammer effects in hydraulic lines. The dampening action protects pump seals, hose connections, and cylinder rod seals from shock loads.

Special versions change this basic operation. The SO40 variant adds an external G1/4 port for pilot control, useful when you need remote valve operation. The SO60 version vents the control spool to the T port, improving release precision in certain circuit designs.

Where the Z2S 22 Check Valve Works Best

Industrial automation systems use the check valve sandwich plate Z2S 22 extensively. Injection molding machines rely on these valves to hold mold platens steady during cooling cycles. Press brakes use them to maintain ram position when hydraulic pumps shut down between bending operations. Robotic arms need the valve to prevent load drift when holding position.

Material handling equipment like forklifts and scissor lifts benefit from the zero-leakage design. A standard spring check valve might allow enough seepage to lower a platform slowly over hours. The Z2S 22 sandwich plate eliminates this problem, maintaining position indefinitely without pump operation.

Wind turbine pitch control systems operate in challenging conditions with temperature swings and contamination risks. The check valve sandwich plate handles these environments when paired with proper filtration. Energy sector applications demand reliability because valve failure during turbine operation can damage expensive gearboxes.

The compact sandwich design matters most in mobile equipment where space comes at a premium. Excavators, cranes, and agricultural machinery pack multiple functions into limited areas. Stacking the Z2S 22 check valve between directional valves and other sandwich plates reduces manifold size compared to traditional pipe-mounted check valves.

Comparing Valve Options

Standard spring-loaded check valves cost less than the Z2S 22, typically ranging from 200 to 500 dollars. They work fine for simple applications but lack pilot control and often show minor leakage. Response speed is slower because the spring must compress before flow begins.

Dual-disc wafer check valves handle larger flows, sometimes exceeding 500 liters per minute. They weigh less than sandwich plates and work well in low-pressure piping systems under 250 bar. However, disc valves can stick closed if contamination gets between the disc and seat. Corrosion resistance is also lower in standard designs.

The check valve sandwich plate Z2S 22 typically costs between 1000 and 1500 dollars depending on the configuration and supplier. This higher price reflects the pilot operation capability, zero-leakage design, and integration benefits. Maintenance costs may be lower over the valve's lifetime because the sandwich design protects internal components from external damage.

Performance comparisons show the Z2S 22 maintaining consistent flow up to 450 liters per minute at 315 bar, while many spring checks start showing pressure drop increases above 300 liters per minute. The pilot-operated design also responds faster to control signals than spring-loaded types because it doesn't fight spring force during opening.

Installation Requirements You Should Know

Mount the check valve sandwich plate Z2S 22 in any orientation, though vertical stacking is most common. Clean both mating surfaces thoroughly before assembly. Any dirt, burrs, or old gasket material can create leak paths that compromise the zero-leakage design.

Apply the provided seal rings to each port before positioning the valve. The seals sit in grooves machined into the sandwich plate face. Make sure seals are properly seated and not twisted, which can cause them to extrude under pressure.

Bolt patterns use six M12 cap screws in a standard ISO pattern. Tighten screws in a star pattern to 70 Nm torque. Overtightening can distort the valve body and cause internal parts to bind. Undertightening allows external leakage and potential pressure loss.

For SO40 versions with external pilot ports, connect the G1/4 fittings to your pilot pressure source. Make sure pilot pressure exceeds cracking pressure by at least 50 percent to ensure complete opening. Insufficient pilot pressure causes partial opening and restricted flow.

Check system cleanliness before startup. The Z2S 22 check valve sandwich plate requires hydraulic oil meeting ISO 4406 cleanliness code 20/18/15 or better. This means fewer than 5000 particles larger than 4 microns per milliliter of fluid. Contamination causes 80 percent of valve failures according to industry maintenance data.

Maintenance and Troubleshooting

Regular filter changes protect the check valve sandwich plate from contamination damage. Change filters at intervals recommended for your hydraulic oil type. Mineral oils like HLP46 run longer between changes than biodegradable fluids, which may need twice as frequent service.

Inspect the valve during system maintenance shutdowns. Look for external oil seepage around the sandwich plate faces, which indicates seal wear or mounting bolt looseness. Internal leakage shows up as actuator drift over time, though this is rare with proper installation.

If the valve develops drift problems, check pilot pressure first. Insufficient pilot pressure may not fully open the valve, causing restricted flow and incomplete position release. Measure actual pressure at the X port under load conditions, not just static pressure.

Noise or shock during valve opening points to missing or damaged pre-opening components. Some older Z2S 22 models lack this feature, and retrofitting to the SO55 version eliminates the problem. Sudden pressure drops create hammering that eventually damages seals and connections throughout the system.

Failed opening usually traces to contamination blocking the pilot control spool. Flushing the system and installing proper filtration fixes most cases. Persistent problems may require valve disassembly and inspection of the ball seat and poppet surfaces for scoring or embedded particles.

Store spare check valve sandwich plates in dry areas away from temperature extremes. Keep protective caps on ports to prevent contamination during storage. Stock replacement seals for NBR or FKM depending on your system requirements, as seal deterioration from shelf aging can occur over several years.

Ordering and Part Number Details

The Z2S 22 check valve sandwich plate uses a structured part number system. Start with Z2S 22, then add the channel designation. A dash mark means dual channel for both A and B sides. The letter A or B alone specifies single channel operation on that side only.

Next comes the cracking pressure code from 1 to 4, representing 3, 5, 7.5, or 10 bar respectively. Higher numbers provide stronger reverse blocking but need more pilot pressure. Then 5X appears in all standard models, followed by optional surface treatment codes like J50 for passivation.

Special versions add codes like SO40 for external pilot ports or SO60 for spool-to-tank venting. The letter V at the end specifies FKM seals instead of standard NBR for high-temperature or aggressive fluid compatibility. A complete example might read Z2S 22 A 2 5X V SO40.

Installation kits with seals and gaskets order separately. Check the Bosch Rexroth catalog for compatible kits matching your valve version. Using wrong seal materials causes rapid failure, especially with fire-resistant hydraulics or biodegradable oils.

Finding Reliable Suppliers

Bosch Rexroth sells directly through their online store and regional distributors. Official channels guarantee genuine parts and proper technical support. Data sheets download from their site using document number R900432915.

BuyRexroth operates as a major distributor with online ordering and immediate shipping for common configurations. Their pricing runs around 1426 dollars for standard Z2S 22 check valve sandwich plates with typical delivery in one to three business days.

Secondary markets on eBay offer used and surplus valves from 500 to 1000 dollars. Buying used makes sense for replacement parts in older equipment, but inspect carefully for damage or wear. Missing or damaged seals may not be obvious in photos.

Industrial suppliers like Hydraulics Online and Pha-Auto carry the Z2S 22 along with complete hydraulic systems. They provide local technical support and can help with installation questions. Bulk purchasers might negotiate better pricing through direct contact with regional Bosch Rexroth representatives.

Chinese manufacturers offer alternatives at lower costs through platforms like Made-in-China. While these may work for less critical applications, the quality and performance characteristics differ from genuine Bosch Rexroth products. Expect variations in pressure ratings, seal materials, and dimensional tolerances.

Fluid Compatibility Considerations

Mineral hydraulic oils like HL and HLP work perfectly with standard NBR seals in the check valve sandwich plate Z2S 22. These remain the most common fluids in industrial hydraulics because of their stable performance and reasonable cost.

Fire-resistant fluids require special attention. HFDU and HFDR types limit maximum pressure to 210 bar instead of the standard 315 bar rating. Operating temperatures should not exceed 60 degrees Celsius with these fluids. Service life may decrease by 30 to 100 percent compared to mineral oil operation.

Biodegradable hydraulics like HETG and HEES work with the Z2S 22 but need more frequent maintenance intervals. These fluids absorb moisture more readily and break down faster than mineral oils. Change filters more often and monitor system cleanliness closely.

Synthetic fluids often require FKM seals instead of standard NBR. The V code in the part number specifies this seal material. Check compatibility tables before selecting a valve for synthetic or exotic fluid systems. Using wrong seal materials causes rapid swelling or hardening that leads to leakage or binding.

Water-glycol fluids may work depending on the specific formulation. Consult Bosch Rexroth technical support with your fluid specifications before ordering. Some water-based fluids attack standard seal materials or corrode internal components.

Performance in Different Environments

Temperature extremes affect check valve sandwich plate Z2S 22 performance. Cold starts below negative 20 degrees require NBR seals, while FKM handles higher temperatures up to 80 degrees ambient. Fluid viscosity changes with temperature, affecting flow characteristics and response time.

Dirty environments demand excellent filtration. Construction and mining equipment face constant contamination from dust, water, and debris. Installing filtration meeting ISO 4406 20/18/15 prevents most contamination problems, but extreme conditions might need even finer filtration.

High-vibration applications benefit from the sandwich plate mounting style. Threaded check valves can loosen over time from vibration, while bolted sandwich plates stay secure. Use thread-locking compound on mounting bolts in severe vibration environments.

Coastal and marine settings expose hydraulic components to salt air and moisture. The optional J50 passivation treatment provides better corrosion resistance for the valve body exterior. Internal components remain protected by hydraulic oil, but moisture contamination becomes a bigger concern near water.

Altitude affects hydraulic performance through pressure and temperature relationships. High-elevation equipment may need different cracking pressure settings because atmospheric pressure differs. Consult with hydraulic engineers for installations above 2000 meters.

Future Developments in Hydraulic Valve Technology

Electronic monitoring integration represents the next step for components like the check valve sandwich plate Z2S 22. Sensors embedded in sandwich plates could report actual flow rates, pressure drops, and internal wear conditions. Predictive maintenance becomes possible when systems detect performance degradation before failure occurs.

Improved seal materials continue advancing. New polymer compounds offer better chemical resistance and longer service life across wider temperature ranges. These materials cost more initially but reduce maintenance downtime and replacement frequency.

Additive manufacturing may change how hydraulic components are produced. 3D printed valve bodies could optimize internal flow paths beyond what machining allows. Complex internal geometries might improve performance while reducing weight and material usage.

Smart hydraulics systems will adjust valve parameters automatically based on operating conditions. A check valve could vary its cracking pressure to match load requirements, improving energy efficiency. Pilot pressures might be modulated for optimal opening speeds under different flow conditions.

The Z2S 22 check valve sandwich plate represents mature technology that reliably serves current industrial needs. While improvements will come gradually, the basic design principles of pilot-operated check valves will likely remain relevant for many years across hydraulic applications worldwide.