The short answer is technically yes, but practically no—at least not with standard ball valves. While you can physically rotate a ball valve handle to restrict flow, doing so creates serious mechanical risks that most engineers learn to avoid. However, specialized V-port ball valves are specifically designed for flow control and perform this task exceptionally well. This distinction matters because using the wrong valve type can lead to premature failure, system noise, and costly downtime.

Why Standard Ball Valves Fail at Flow Control

Standard ball valves are quarter-turn devices designed for on-off service. Their internal geometry creates a "quick-opening" characteristic where 80-90% of max flow occurs within the first 20-30% of travel. This high process gain makes precise throttling nearly impossible, leading to actuator hunting and instability.

The Pressure Recovery Problem

Ball valves have high pressure recovery ($F_L$), which increases cavitation risk. The cavitation index ($\sigma$) predicts this:

$$ \sigma = \frac{P_{upstream} - P_{vapor}}{P_{upstream} - P_{downstream}} $$When $\sigma$ drops below 2.5, incipient cavitation begins. Standard ball valves reach this threshold much faster than globe valves.

| Parameter | Standard Ball Valve | Globe Valve | Engineering Impact |

|---|---|---|---|

| Pressure Recovery Factor ($F_L$) | 0.85 - 0.95 | 0.60 - 0.80 | Higher $F_L$ = Greater cavitation risk |

| Critical Throttling Range | 0-20% open | 10-90% open | Ball valve has minimal usable control range |

| Trim Options | Single-stage only | Multi-stage cages | Globe valves handle high pressure drops better |

"Wire drawing" occurs when high-velocity fluid cuts grooves into sealing surfaces. Soft seats (PTFE/PEEK) cannot withstand throttling pressure differentials above 50 psi. A chemical plant case study showed soft-seat failure in steam service after just three weeks. Rule: Never use soft-seat ball valves for continuous throttling.

Floating vs Trunnion Mounted: Structure Matters

- Floating Ball: Relies on inlet pressure to push ball against seat. Creates high, unpredictable friction torque during throttling, causing stick-slip and poor control.

- Trunnion Mounted: Fixed ball supported by shafts. Spring-loaded seats create seal. Torque is consistent and proportional, mandatory for throttling applications above ANSI Class 600 or NPS 4.

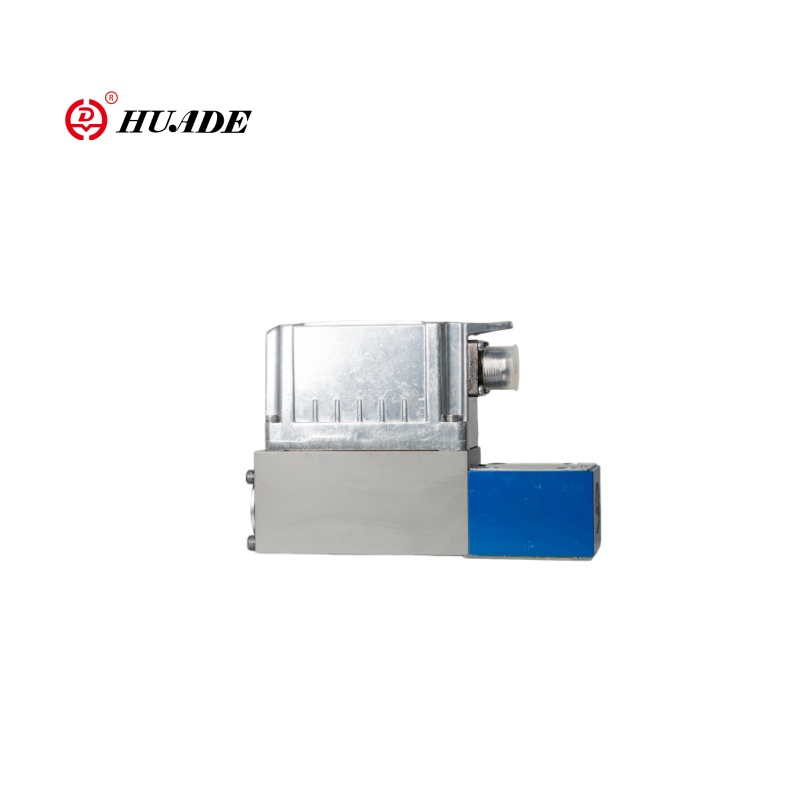

V-Port Ball Valves: Purpose-Built for Control

V-port valves feature a V-shaped notch (15°, 30°, 60°, etc.) that transforms performance. This geometry provides an equal percentage flow characteristic and rangeability up to 300:1.

| Metric | Standard Ball Valve | V-Port Ball Valve (60°) | Globe Valve |

|---|---|---|---|

| Flow Characteristic | Quick-opening | Equal percentage | Linear/Equal % |

| Rangeability | 10:1 | 300:1 | 50:1 |

| Shearing Action | Poor | Excellent | None |

V-port valves offer a unique shearing action. The sharp V-notch acts like scissors against the seat, cutting through fibers and slurries that would clog globe valves. This makes them superior for pulp, paper, and wastewater applications.

Material Selection for Throttling Service

Soft Seats: Limited to low pressure drop (< 50 psi) and moderate temps.

Metal Seats: The workhorse. Stellite or Tungsten Carbide coatings (HVOF) are essential for high-velocity, erosive, or cavitating service.

Critical Safety Warnings

A 2001 industrial fatality occurred when an operator throttled high-pressure oxygen with a standard ball valve. The resulting supersonic velocity (>300 ft/s) ignited metal components. Never use standard ball valves to throttle pure oxygen. Oxygen valves require specific materials (Monel) and velocity limits (< 30 ft/s).

Throttling ball valves generate high noise (10-20 dBA higher than labyrinth valves). Levels above 110 dBA cause vibration fatigue, cracking welds and loosening positioners.

Economic Reality

While standard ball valves are cheap initially, throttling service kills them in 6-12 months. V-port valves cost 1.5-3x more but offer lower TCO than globe valves and significantly lower weight.

The Verdict: Use standard ball valves for isolation. Use V-port trunnion valves for control. Using a standard valve for throttling is a false economy that leads to maintenance headaches and potential safety risks.