Think of a proportional flow control valve as the "smart dimmer switch" of hydraulic systems. Just like a dimmer switch lets you control how bright a light gets, these valves let you control exactly how fast hydraulic oil flows through your system. [First understand what proportional valves are.]

Why this matters:

Traditional hydraulic valves are either fully open or fully closed - like a regular light switch. Proportional valves give you smooth, precise control - like that dimmer switch. This smooth control means:

- Less shock and vibration in your machinery

- More precise movement of hydraulic cylinders and motors

- Better energy efficiency

- Smoother operation overall

The Basic Concept

Here's how it works in simple terms:

Electrical Input

You send an electrical signal (usually 4-20 mA or 0-10V) to the valve

Proportional Response

The valve opens proportionally to that signal

Flow Control

More signal = more flow, less signal = less flow

Smooth Operation

Changes happen gradually, not suddenly

This proportional relationship is what makes these valves so valuable in modern hydraulic systems.

Why They Matter: The Evolution from Simple to Smart Control

The Old Way: Bang-Bang Control

In the past, most hydraulic systems used simple on/off valves (called "bang-bang" control). These valves had two settings:

- Fully Open: Maximum flow

- Fully Closed: No flow

Problems with bang-bang control:

- Sudden pressure spikes when valves opened or closed quickly

- Vibration and mechanical stress on equipment

- Difficulty achieving precise speeds or positions

- Energy waste from constant full-flow operation

The New Way: Proportional Control

Proportional valves changed everything by providing:

Smooth Acceleration

Instead of jerky start-stop motion, machinery moves smoothly from rest to full speed.

Precise Speed Control

You can set exact speeds for different parts of a machine cycle.

Energy Efficiency

The system only uses the flow it needs, when it needs it.

Better Product Quality

Smoother motion means better results in manufacturing processes.

Reduced Maintenance

Less shock and vibration means longer equipment life.

Real-World Impact

Consider an injection molding machine making plastic parts:

- Old system: The injection ram moved at full speed or stopped completely, causing defects and wasted material

- New system: The ram speed varies smoothly throughout the injection cycle, producing consistent, high-quality parts

This evolution from simple to smart control has made proportional valves essential in modern manufacturing.

How They Work: Inside the Technology

Understanding how proportional flow control valves work helps you choose and use them better. Let's break down the key components.

[Learn the complete working principle of proportional valves]

1. The Proportional Solenoid: The Brain

The proportional solenoid is like the valve's brain. Unlike regular solenoids that are either on or off, proportional solenoids can create different amounts of force based on the electrical signal they receive.

How it works:

- Receives electrical signal (current or voltage)

- Creates magnetic force proportional to that signal

- More signal = more magnetic force

- This force moves the valve's internal parts

Key features:

- Uses DC power for smooth operation

- Often uses PWM (pulse-width modulation) signals around 200 Hz

- May include "dither" - tiny vibrations that reduce friction

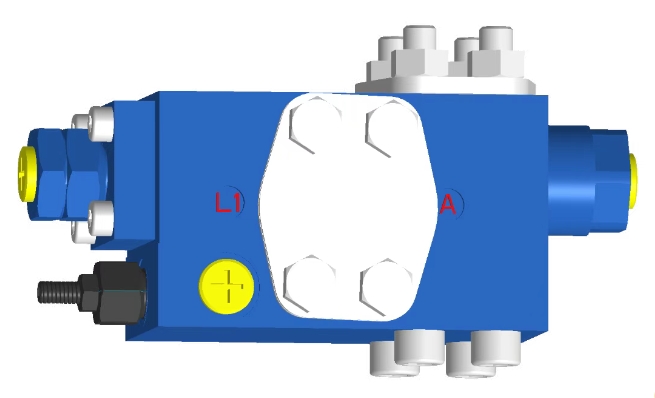

2. The Spool and Valve Body: The Flow Controller

Inside the valve body sits a precision-machined cylinder called a spool. This spool slides back and forth to control flow.

Spool Design Features

- Metering notches: Special shapes (V, U, or rectangular) cut into the spool that control how flow changes with spool position

- Overlap characteristics: How the spool edges align with ports affects valve response

Flow Characteristics

- Linear flow: Flow increases proportionally with spool movement

- Progressive flow: Flow increases more at larger openings, giving finer control at low flows

3. Pressure Compensation: Maintaining Consistent Flow

One of the most important features in quality proportional valves is pressure compensation. This system ensures that flow stays constant even when load pressure changes.

The problem without compensation: If you're lifting a heavy load, the back-pressure increases, reducing flow even if the valve opening stays the same.

The solution: A pressure compensator automatically adjusts the pressure drop across the main spool to keep it constant.

Benefits:

- Flow depends only on valve signal, not on load

- Predictable system behavior

- Easier programming and control

4. Feedback Systems: Ensuring Accuracy

Higher-end proportional valves include feedback systems that monitor the actual spool position and compare it to the desired position.

| Valve Type | Feedback | Accuracy | Cost | Applications |

|---|---|---|---|---|

| Open-loop valves | No feedback | Moderate | Lower | Basic applications |

| Closed-loop valves | LVDT sensors | High | Higher | Precision applications |

Types of Proportional Flow Control Valves

Proportional valves come in several configurations. Understanding these types helps you choose the right one for your application.

By Drive Mechanism

Direct-Acting Valves

The solenoid directly moves the spool

- Fast response (5-10 milliseconds)

- Compact size

- Simple design

Limitations: Limited to smaller flows (<50 L/min) and pressures (<210 bar)

Best for: Small systems, medical devices, pilot stages for larger valves

Pilot-Operated Valves (Two-Stage)

A small pilot valve controls oil flow to move the main spool

- Can handle high flows (up to 1600 L/min)

- High pressures (up to 350 bar)

Limitations: Slower response (~100 ms)

Best for: Heavy machinery, large industrial systems, high-power applications

By Function

Flow Control Valves

- Primary job is controlling flow rate

- Usually 2-way or 3-way configurations

- Often include pressure compensation

- Control actuator speed

Directional Control Valves

- Control both flow and direction

- Typically 4-way, 3-position valves

- Replace multiple simple valves

- Control cylinder or motor direction and speed

Pressure Control Valves

- Control system pressure rather than flow

- Include relief valves and pressure reducing valves

- Maintain safe operating pressures

Proportional vs. Other Valve Types

Understanding how proportional valves compare to other technologies helps you make better decisions.

Proportional vs. On/Off Valves

| Feature | On/Off Valves | Proportional Valves |

|---|---|---|

| Control Type | Binary (open/closed) | Continuous (variable) |

| Flow Control | Full flow or no flow | Any flow from 0-100% |

| System Shock | High (sudden changes) | Low (smooth transitions) |

| Energy Use | Often wasteful | Efficient (match demand) |

| Complexity | Simple circuits | More complex electronics |

| Cost | Low initial cost | Higher initial cost |

Proportional vs. Servo Valves

| Feature | Proportional Valves | Servo Valves |

|---|---|---|

| Accuracy | Good (±2-5%) | Excellent (±0.5%) |

| Response Speed | Moderate (2-50 Hz) | Very fast (>100 Hz) |

| Cost | Moderate | High (10-20x more) |

| Contamination Tolerance | High | Low (needs very clean oil) |

| Complexity | Moderate | High |

| Maintenance | Standard | Specialized |

When to Choose Each Type

Choose On/Off Valves when:

- You only need simple open/closed control

- Cost is the primary concern

- The application can tolerate shock and vibration

- Precise control isn't required

Choose Proportional Valves when:

- You need variable speed or position control

- Smooth operation is important

- Energy efficiency matters

- Moderate precision is sufficient

-

Working in typical industrial environments

For hydraulic specifics, see hydraulic proportional valves guide

Choose Servo Valves when:

- Ultra-high precision is required

- Very fast response is needed

- Cost is secondary to performance

- You can maintain very clean hydraulic fluid

- Application demands it (aerospace, testing)

Key Performance Metrics You Need to Know

When selecting a proportional valve, several performance metrics determine how well it will work in your application.

Flow and Pressure Ratings

Maximum Flow Rate

- Usually specified at a standard pressure drop (like 5 bar or 70 psi)

- Typical ranges: 7-1000 L/min (2-260 GPM)

- Choose based on your actuator speed requirements

Maximum Pressure

- Safe operating pressure limit

- Typical ranges: 280-400 bar (4000-5800 psi)

- Must exceed your system's maximum pressure

Pressure Drop

- Pressure lost across the valve at rated flow

- Lower is better for efficiency

- Typical: 5-35 bar (70-500 psi) at rated flow

Accuracy and Repeatability

Hysteresis

Output difference when approaching the same point from different directions

- Typical: 2-5% of full scale

- Lower is better for precision applications

Linearity

How closely the valve's flow follows the input signal

- Typical: ±2% of full scale

- Linear valves are easier to control

Repeatability

Consistency when returning to the same input signal

- Typical: ±1-3% of full scale

- Important for consistent production

Deadband

Range of input signal that produces no output

- Typical: 2-5% of full signal range

- Caused by spool overlap, necessary for sealing

Performance Comparison Table

| Valve Type | Flow Range | Pressure | Response Time | Hysteresis | Contamination Tolerance | Relative Cost |

|---|---|---|---|---|---|---|

| Basic Proportional | 7-100 L/min | Up to 280 bar | 20-100 ms | 3-5% | High | 2-4x |

| Closed-Loop Proportional | 7-1000 L/min | Up to 350 bar | 10-50 ms | 1-2% | High | 4-8x |

| Servo-Proportional | 10-500 L/min | Up to 350 bar | 5-20 ms | <1% | Moderate | 8-15x |