Have you ever wondered how heavy machinery like excavators and bulldozers get their incredible power? The secret often lies in something called an axial piston pump. But here's a question that puzzles many people: Do axial piston pumps actually create pressure?

The short answer is yes – but not in the way you might think. Let's dive into this fascinating world of hydraulic power and discover how these amazing machines work.

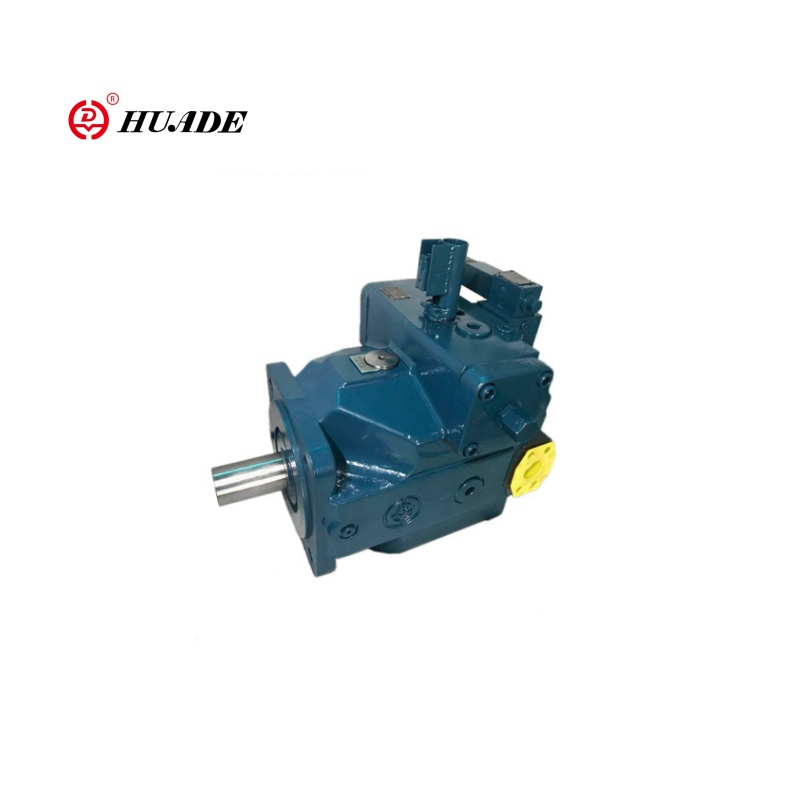

What Exactly Is an Axial Piston Pump?

Think of an axial piston pump as the heart of a hydraulic system. Just like your heart pumps blood through your body, this pump moves hydraulic fluid through machines to make them work.

For complete understanding, see how axial piston pumps work.

The name "axial piston" comes from how it's built:

- Axial means the pistons move back and forth along the same line as the main shaft

- Piston refers to the small cylinders that do the actual pumping work

These pumps are special because they can handle extremely high pressure – sometimes up to 6,500 PSI (pounds per square inch). That's like having the weight of four cars pressing down on every square inch!

[For piston pump comparison, see axial vs radial designs]

Do They Really Create Pressure?

Here's where it gets interesting. There's a common saying in engineering: "Pumps create flow, not pressure." While this sounds smart, it's only part of the story.

The truth is: Axial piston pumps create flow first, then pressure happens when that flow meets resistance.

Imagine squeezing a garden hose while water is flowing through it. The pump (your faucet) creates the flow, but when you squeeze the hose (creating resistance), pressure builds up. The same thing happens in hydraulic systems.

How This Works in Real Life

It pushes a fixed amount of hydraulic oil with each turn

This could be a heavy load, a closed valve, or friction in the system

The fluid has nowhere else to go, so pressure increases

This pressure is what lifts heavy objects or moves machinery

Inside an Axial Piston Pump

Let's break down the main components that make these pumps work:

1. Cylinder Block

This is like the main body that holds everything together. It spins around and has holes for the pistons.

2. Pistons

These are small cylinders that move back and forth. Most pumps have 7 or 9 pistons (always an odd number to make the flow smoother).

3. Swashplate

This angled plate is the clever part that turns spinning motion into back-and-forth piston movement. Think of it like a cam in a car engine.

4. Drive Shaft

This connects to a motor and makes everything spin.

5. Valve Plate

This controls where the fluid goes in and out, like traffic lights for hydraulic fluid.

The Pumping Process

The process is surprisingly simple:

Step 1: Suction Phase

- Pistons pull back, creating empty space

- Hydraulic fluid gets sucked in through the inlet

- It's like using a syringe to draw up medicine

Step 2: Discharge Phase

- Pistons push forward, squeezing the fluid

- Pressurized fluid shoots out through the outlet

- This creates the flow that can build up pressure

This happens thousands of times per minute, creating a steady stream of high-pressure fluid.

Two Types: Fixed vs. Variable Displacement

Axial piston pumps come in two main flavors.

- The swashplate angle never changes

- They always pump the same amount of fluid

- Simple and reliable, like a basic car engine

- The swashplate angle can be adjusted

- You can control how much fluid they pump

- More complex but much more flexible

- Like having a car with a continuously variable transmission

Real-World Applications

Axial piston pumps are everywhere, even if you don't see them:

Construction Equipment

- Excavators use them to lift tons of dirt

- Bulldozers push through tough terrain

- Cranes lift heavy materials to great heights

Industrial Machines

- Hydraulic presses shape metal parts

- CNC machines cut with incredible precision

- Injection molding machines make plastic products

Transportation

- Aircraft use them for landing gear and flight controls

- Ships rely on them for steering systems

- Even some car air conditioning systems use them

Agriculture

- Tractors use hydraulic power for attachments

- Harvesters operate complex cutting mechanisms

- Irrigation systems move water efficiently

The Pressure Capabilities: How Strong Are They?

Different axial piston pumps can handle different pressure levels:

- Medium-pressure models: Up to 3,600 PSI

- High-pressure models: 5,000 to 6,500 PSI

- Specialized pumps: Some can go even higher

To put this in perspective, a typical car tire has about 30-35 PSI. These pumps can create pressure that's 100-200 times stronger!

Why Pressure Matters

Pressure is what gives hydraulic systems their incredible strength. Here's why:

Force Multiplication

Using Pascal's principle (named after a smart French guy), hydraulic systems can multiply force. A small force on a small piston can create a huge force on a large piston.

Precise Control

High pressure allows for very precise movements, which is why hydraulic systems are used in aircraft controls and surgical equipment.

Compact Power

Hydraulic systems can deliver enormous power from relatively small components, making them perfect for mobile equipment.

Common Problems and Solutions

Like any machine, axial piston pumps can have issues:

Pressure Pulsation

Problem: The flow isn't perfectly smooth, creating vibrations

Solution: Use an odd number of pistons and special valve designs

Internal Leakage

Problem: Fluid leaks inside the pump, reducing efficiency

Solution: Regular maintenance and quality hydraulic fluid

Overheating

Problem: High pressure creates heat, which can damage seals

Solution: Proper cooling systems and pressure relief valves

Maintenance Tips: Keeping Your Pump Happy

To keep an axial piston pump working well:

- Keep the fluid clean - Dirty oil is the enemy of hydraulic systems

- Change filters regularly - Think of them as the pump's air filters

- Monitor pressure and temperature - Too much of either can cause problems

- Check for leaks - External leaks waste fluid; internal leaks reduce efficiency

- Follow maintenance schedules - Regular check-ups prevent big problems

Comparing Axial Piston Pumps to Other Types

Gear pumps: Simpler, cheaper, but limited pressure

Axial piston: More complex, expensive, but much higher pressure capability

Vane pumps: Quieter, smoother flow, but not as strong

Axial piston: Louder, but can handle extreme pressures

Centrifugal: Great for moving lots of water at low pressure

Axial piston: Perfect for high-pressure, precise applications

The Future of Axial Piston Pumps

Technology keeps improving these pumps:

Smart Controls

New pumps can automatically adjust their output based on what the system needs, saving energy and improving performance.

Better Materials

Advanced materials make pumps last longer and handle higher pressures.

Digital Monitoring

Sensors can predict when maintenance is needed, preventing unexpected breakdowns.

Energy Efficiency: Why It Matters

Modern axial piston pumps are incredibly efficient:

- Volumetric efficiency: Up to 96% of the fluid actually gets pumped

- Mechanical efficiency: Very little energy is wasted as heat

- Variable displacement: Only pumps what's needed, saving energy

This efficiency is important because:

- It saves money on electricity

- It reduces heat generation

- It's better for the environment

Choosing the Right Pump

When selecting an axial piston pump, consider:

Pressure Requirements

How much pressure does your system actually need? Don't oversize – it wastes energy and money.

Flow Rate

How much fluid needs to move per minute? This determines the pump size.

Control Type

Do you need fixed output or variable control? Variable costs more but offers flexibility.

Environment

Will it work indoors or outdoors? In clean or dirty conditions? Temperature extremes?

Budget

Balance upfront cost with long-term operating costs and reliability.

Safety Considerations

- Never work on pressurized systems

- Always use proper safety equipment

- Be trained before operating hydraulic machinery

- Respect the power – hydraulic fluid under pressure can cut through skin

Understanding System Integration

Axial piston pumps don't work alone. They're part of a complete hydraulic system that includes:

Reservoir

Stores hydraulic fluid and allows it to cool

Filters

Keep the fluid clean and protect system components

Valves

Control flow direction, pressure, and speed

Actuators

Convert hydraulic power back into mechanical work (cylinders, motors)

Cooling System

Manages heat generated by the system

Troubleshooting Common Issues

Low Pressure Output

- Check for internal leakage

- Verify pump displacement setting

- Look for external leaks

- Check relief valve setting

Excessive Noise

- Check fluid level and quality

- Look for air in the system

- Verify proper mounting

- Check for worn components

Overheating

- Check cooling system

- Verify proper fluid viscosity

- Look for excessive pressure

- Check for blocked filters

The Bottom Line

So, do axial piston pumps create pressure? Absolutely! While they primarily create flow, this flow becomes pressure when it meets resistance in the hydraulic system. This pressure is what gives hydraulic equipment its incredible power and precision.

These pumps are engineering marvels that have revolutionized countless industries. From the excavator digging your foundation to the aircraft landing safely at the airport, axial piston pumps are working behind the scenes to make our modern world possible.

Understanding how they work helps us appreciate the incredible engineering that goes into everyday machines. The next time you see a piece of heavy equipment working, you'll know there's probably an axial piston pump inside, quietly creating the pressure needed to move mountains – literally!

Key Takeaways

- Axial piston pumps create flow, which becomes pressure when it meets resistance

- They can handle extremely high pressures (up to 6,500+ PSI)

- They're used in construction, aerospace, industrial, and agricultural equipment

- Proper maintenance is crucial for long life and reliable operation

- Variable displacement pumps offer better energy efficiency and control

- They're more complex than other pump types but offer superior performance for high-pressure applications

Whether you're a student learning about hydraulics, a technician maintaining equipment, or just someone curious about how powerful machines work, understanding axial piston pumps opens up a fascinating world of engineering and technology.