Imagine having the power to lift 50 tons with the touch of a button, or controlling massive construction equipment with millimeter precision. This isn't science fiction – it's the incredible reality of hydraulic stations at work every day around the world!

From the towering cranes building tomorrow's skyscrapers to the precise robotic arms manufacturing life-saving medical devices, hydraulic power units (HPUs) are the unsung heroes powering our modern world. These remarkable machines transform simple mechanical energy into unstoppable hydraulic force, making the impossible possible.

A hydraulic station – also known as a hydraulic power unit, HPU system, or hydraulic pump station – is far more than just industrial equipment. It's the beating heart of countless industries, the force multiplier that lets humans move mountains, and the precision tool that shapes our future.

In this comprehensive guide, we'll unlock the secrets behind these engineering marvels – from fundamental principles to cutting-edge 2025 innovations. Whether you're an aspiring engineer, a curious student, or a professional looking to deepen your knowledge, you're about to discover how hydraulic stations are revolutionizing industries and creating possibilities that seemed impossible just decades ago.

What is a Hydraulic Station?

Basic Definition

A hydraulic station is a complete power system that pumps fluid (usually oil) under high pressure to operate hydraulic equipment. It's like having a powerful water pump, but instead of pumping water for your garden, it pumps special oil to power heavy machinery.

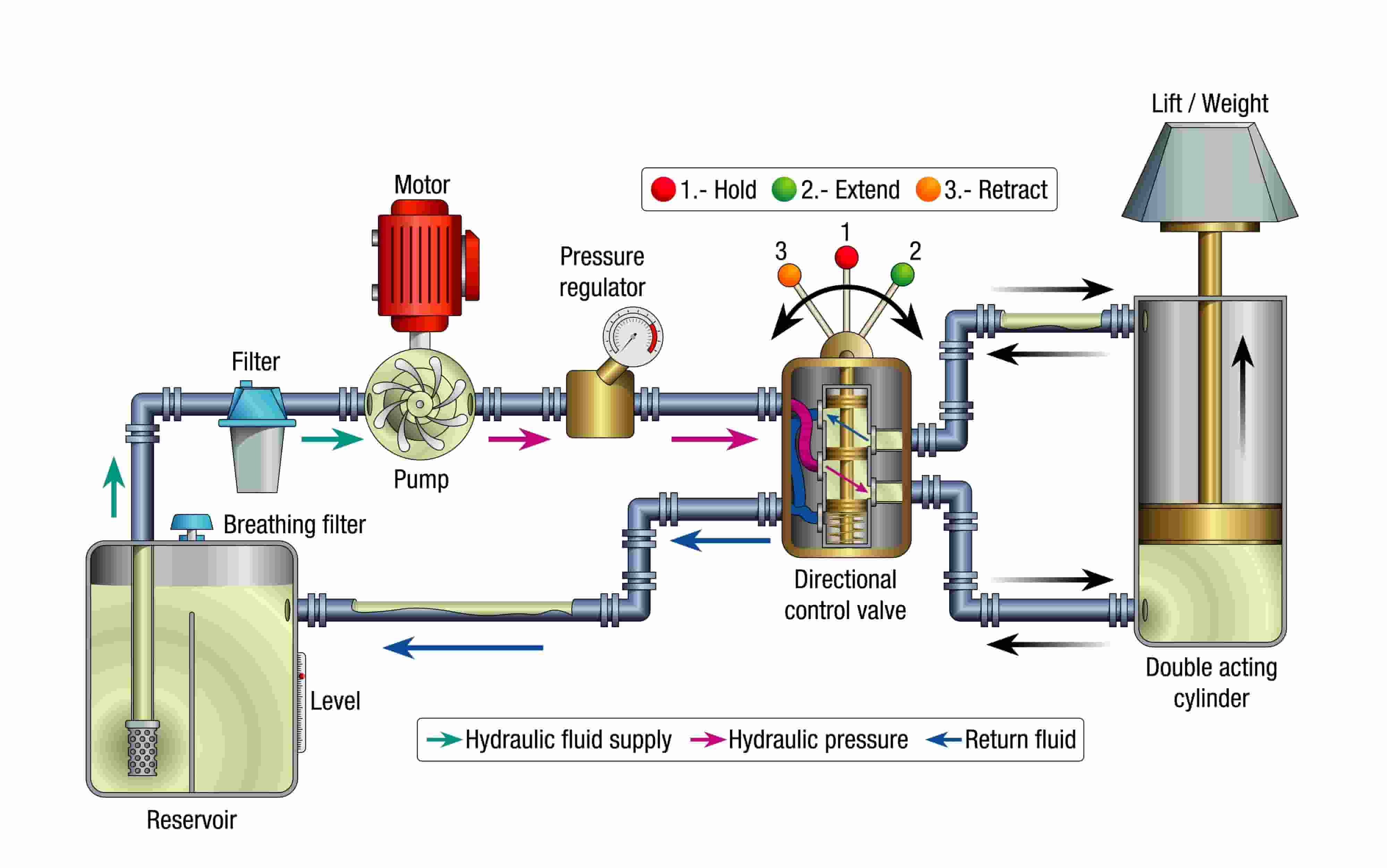

The hydraulic station includes several key parts working together:

- A pump to create pressure

- A motor to run the pump

- A tank to store hydraulic fluid

- Valves to control flow and pressure

- Filters to keep the fluid clean

What Makes Hydraulic Power Units Special?

Hydraulic pump stations are everywhere in modern industry because they offer something truly extraordinary – incredible power in a remarkably compact package. Here's why these HPU systems are revolutionizing how we work:

- High Power Output: A small hydraulic station can generate enough force to lift a car or move tons of material.

- Precise Control: Operators can control speed and force with amazing accuracy – perfect for delicate operations.

- Reliability: Well-maintained hydraulic stations can run for years without major problems.

- Versatility: One hydraulic station can power multiple pieces of equipment at the same time.

- Intelligence (2025 Feature): Modern systems now feature self-diagnostics, predictive maintenance, and remote monitoring capabilities.

The Science Behind Hydraulic Stations

Pascal's Law – The Foundation

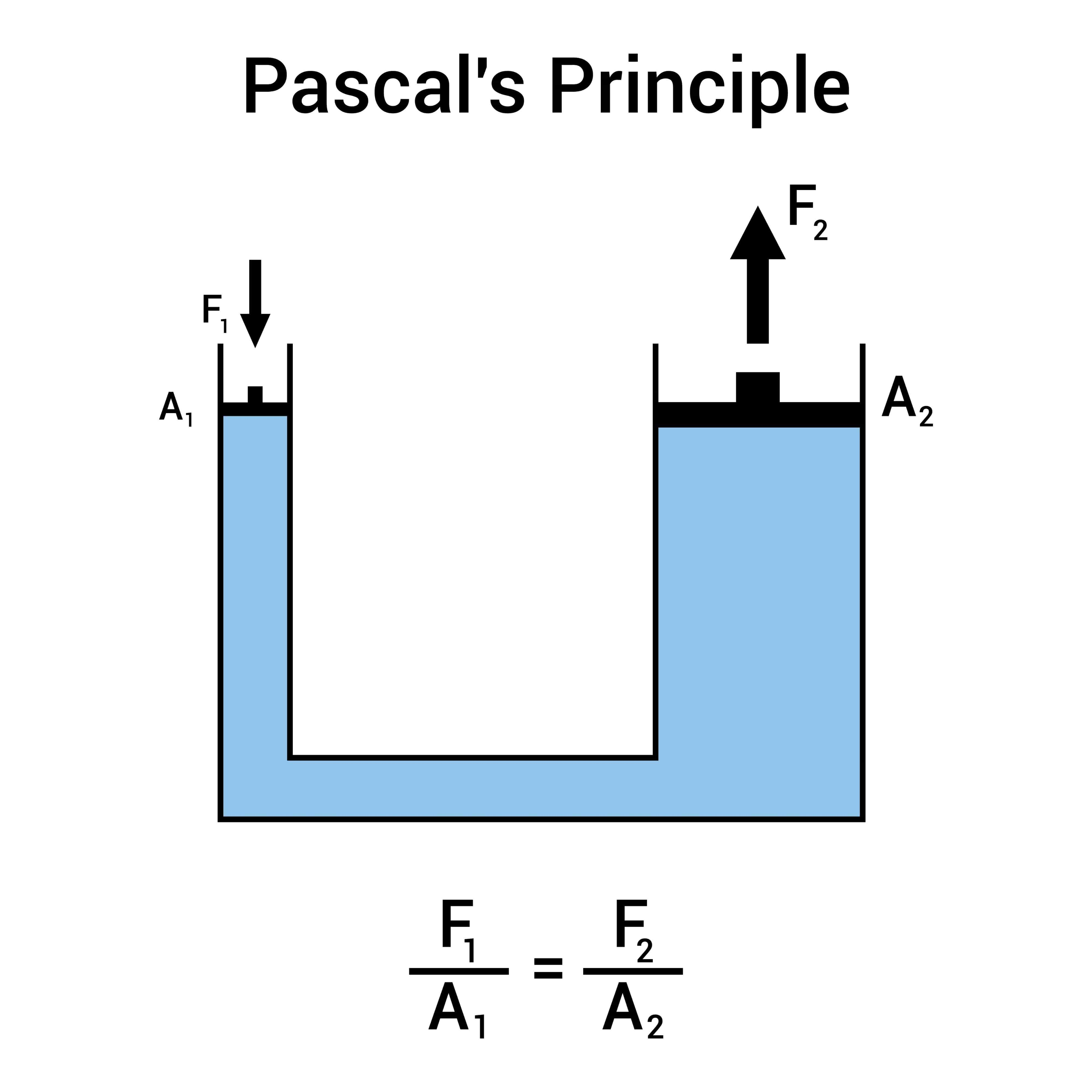

All hydraulic systems work because of Pascal's Law, discovered by French scientist Blaise Pascal in the 1600s. This law says that when you apply pressure to a confined fluid (like oil in a closed system), that pressure spreads equally in all directions.

Here's a simple way to understand it: Imagine you have a water balloon. When you squeeze one part, the pressure goes everywhere inside the balloon equally. Hydraulic systems use this principle to transfer power.

How Force Gets Multiplied

The real magic happens when hydraulic systems multiply force. Here's how:

If you have two connected cylinders – one small and one large – and you push down on the small one, the large one will push up with much more force. The trade-off is that the large cylinder moves a shorter distance.

This is why hydraulic jacks can lift heavy cars with just a small hand pump!

Hydraulic Fluid Properties

The fluid used in hydraulic systems isn't just any liquid. It has special properties:

- Non-compressible: Unlike air (which compresses easily), hydraulic oil doesn't compress much. This means all the pressure you create gets transferred directly to do work.

- Lubricating: The fluid also lubricates all the moving parts, reducing wear and tear.

- Heat Transfer: It helps carry heat away from hot components.

- Stable: Good hydraulic fluid doesn't break down easily under pressure and heat.

Key Components of a Hydraulic Station

Power Generation Components

Hydraulic Pump

The pump is the heart of any hydraulic station. It sucks hydraulic fluid from the tank and pushes it out under high pressure. There are three main types:

- Gear Pumps: Simple, reliable, and affordable. Good for basic applications.

- Vane Pumps: Quieter and more efficient. Used in medium-duty applications.

- Piston Pumps: Most powerful and precise. Used for heavy-duty and high-pressure work.

2025 Innovation: Modern pumps increasingly feature variable displacement with electronic control, allowing real-time optimization of flow and pressure based on actual load demands.

Electric Motor or Engine

This provides the mechanical power to run the pump. Most hydraulic stations use electric motors because they're easy to control, clean, and reliable. For portable units, gasoline or diesel engines are common.

2025 Advancement: Variable Frequency Drives (VFDs) are now standard in most industrial installations, allowing motors to run at optimal speeds and dramatically reducing energy consumption.

Hydraulic Tank (Reservoir)

The tank stores hydraulic fluid and serves several purposes: providing supply to the pump, allowing air bubbles to separate, cooling the fluid, and letting contaminants settle. Tank size typically equals 2-3 times the pump's flow rate per minute.

Control and Safety Components

- Pressure Relief Valve: A critical safety component. When pressure gets too high, this valve automatically opens to prevent damage.

- Directional Control Valves: These control where the fluid flows (extend, retract, or stop). Modern Electro-hydraulic proportional valves enable infinitely variable control.

- Flow Control Valves: Regulate how fast fluid flows, controlling speed.

- Filters: Remove dirt, metal particles, and water. Smart Filtration (2025): Modern filters include clog sensors that alert operators before flow restriction becomes problematic.

Advanced Monitoring and Control Systems

- Pressure Gauges and Sensors: Modern systems combine gauges with digital transducers for real-time monitoring and safety triggers.

- Temperature Monitoring: Advanced systems offer multi-point sensing and predictive alerts for thermal issues.

- Electronic Controllers and PLCs: Most industrial stations now feature Industry 4.0-ready controllers with cloud integration for remote monitoring and optimization.

Modern Innovations in Hydraulic Technology (2025)

[Image of electro-hydraulic servo system schematic]Electro-Hydraulic Servo Systems

Electro-hydraulic servo systems represent the cutting edge of hydraulic control technology, combining the power of hydraulics with the precision of electronic control.

What are Servo Hydraulic Systems?

An electro-hydraulic servo system uses electronic feedback control to achieve extremely precise positioning, force control, and motion profiles. Unlike conventional hydraulic systems with simple on/off valves, servo systems continuously adjust valve position thousands of times per second to achieve exact performance.

Benefits of Servo Hydraulic Technology

- Extreme Precision: Position accuracy within micrometers.

- Programmable Performance: Store and recall complex motion profiles.

- Energy Efficiency: Only uses hydraulic power when actually performing work.

- Better Product Quality: Consistent, repeatable performance improves manufacturing outcomes.

IoT and Smart Monitoring Systems

The integration of Internet of Things (IoT) technology is transforming hydraulic stations from passive equipment into intelligent, self-aware systems.

- Real-Time Condition Monitoring: Continuously tracks fluid condition, component health (vibration, response times), and operating parameters.

- Predictive Maintenance: Machine learning algorithms analyze sensor data to predict component failures days or weeks in advance, reducing unplanned downtime by 50-70%.

- Integration: Connects to ERP and production systems for automated maintenance scheduling.

Variable Frequency Drive (VFD) Technology

Variable Frequency Drives are revolutionizing efficiency by allowing precise control of electric motor speed.

How it works: Instead of running at constant speed and dumping excess flow (wasting energy), VFDs adjust the motor speed to match the actual hydraulic demand.

Energy Savings:

- Injection molding machines: 30-60% reduction

- Hydraulic presses: 40-70% reduction

- General industrial equipment: 20-50% reduction

Hybrid Hydraulic-Electric Systems

The newest frontier in 2025 is the emergence of hybrid systems combining hydraulic power with electric drive technology. This includes Electro-Hydraulic Actuators (EHA) and Energy Recovery Systems that capture energy during deceleration.

How Hydraulic Stations Work: Step-by-Step Process

[Image of hydraulic system flow circuit diagram]Understanding how a hydraulic station works is easier when you follow the fluid through its complete journey:

- Fluid Intake: The pump draws fluid from the tank through a suction strainer.

- Pressurization: The pump compresses the fluid and pushes it into the system at high pressure (500 to 10,000+ PSI). 2025 Feature: Variable displacement pumps automatically adjust output to match demand.

- Flow Control: Valves direct the fluid where it's needed, acting like traffic controllers. Proportional valves allow for smooth, variable control.

- Work Performance: Pressurized fluid reaches actuators (cylinders/motors) where hydraulic energy converts back to mechanical energy.

- Return Flow: Fluid flows back to the tank through return filters to catch contamination.

- Conditioning: Back in the tank, the fluid cools down, releases air bubbles, and settles before the next cycle.

Open vs. Closed Loop Systems

- Open Loop: Fluid returns directly to the tank. Benefits: Better cooling, simpler design, lower cost.

- Closed Loop: Fluid circulates directly between pump and actuators. Benefits: More compact, higher efficiency, faster response.

Types of Hydraulic Stations

By Pump Configuration

- Fixed Displacement: Simple, reliable, low cost. Good for constant-speed applications.

- Variable Displacement: Better energy efficiency and control. Modern standard for industrial apps.

By Power Source

- Electric: Most common in factories. Precise, clean, easy to automate.

- Engine-Driven: Gasoline or diesel. Portable and independent, perfect for outdoor work.

By Portability

- Stationary: Permanently installed, larger, serves multiple machines.

- Portable: Wheeled or hand-carried, self-contained, for field service.

By Pressure Rating

- Low Pressure (<1,000 PSI): Basic applications, simpler maintenance.

- Medium Pressure (1,000-3,000 PSI): Standard industrial use.

- High Pressure (>3,000 PSI): Max power in min space. Heavy-duty work.

Applications Across Industries

Construction and Heavy Equipment

- Excavators: Controlling boom, arm, bucket, and tracks.

- Cranes: Providing smooth lifting control with safety load monitoring.

- Concrete Pumps: Pushing concrete through long hoses.

Manufacturing and Industrial

- Machine Tools: Press brakes, hydraulic presses, injection molding.

- Material Handling: Forklifts, conveyor positioning, robotic systems.

Agriculture and Farming

- Tractors: Power steering, implement control, loaders.

- Harvesting: Combines and balers use hydraulics for crop processing.

Automotive and Transportation

- Vehicle Lifts: Essential for repair shops.

- Garbage Trucks: Compacting mechanisms.

- Dump Trucks: Raising and lowering beds.

Marine, Offshore & Aerospace

- Marine: Steering systems, deck cranes, anchor windlasses.

- Offshore: Drilling rigs and pipe handling (often with remote monitoring).

- Aircraft: Landing gear, flight controls, brakes (highly redundant systems).

Performance Factors and Advantages

Key Performance Metrics

- Flow Rate (GPM/LPM): Determines speed.

- Operating Pressure (PSI/Bar): Determines force.

- Power (HP): Calculated based on flow and pressure.

- Efficiency: Typically 70-85%. VFDs can push this higher.

Advantages of Hydraulic Stations

- High Power-to-Weight Ratio: More power per pound than most sources.

- Precise Control & Smooth Operation: Vibration-free, accurate motion.

- Linear Motion: Simple straight-line force without complex linkages.

- Instant Reversibility: Change direction without stopping.

- Overload Protection: Relief valves prevent breakage.

- Energy Efficiency (2025): VFDs and load-sensing allow hydraulics to rival electric systems.

Maintenance and Troubleshooting

Preventive Maintenance

- Fluid Management: Test contamination quarterly. Change based on condition, not just time.

- Filter Maintenance: Check differential pressure. Use smart alerts.

- Component Inspection: Monitor pumps for noise, check valves for leaks, inspect hoses.

Common Problems and Solutions

Overheating: Undersized cooling or dirty fluid. Solution: Clean fluid, check coolers.

Contamination: Poor filtration or damaged seals. Solution: Upgrade filtration, add water removal.

Noise/Vibration: Cavitation (air in fluid) or worn pump. Solution: Bleed air, secure mounting.

Slow Operation: Worn pump or clogged filters. Solution: Rebuild pump, change filters.

Safety Considerations

- Pressure Hazards: Always depressurize before maintenance.

- Fluid Hazards: Watch for injection injuries and burns.

- Smart Features: Modern systems have automatic emergency stops.

Future Trends and Conclusion

Future Trends

- Digitalization & AI: Predictive analytics and Digital Twins for simulation.

- Sustainability: Biodegradable fluids, energy recovery, and carbon-neutral systems.

- Miniaturization: Compact high-pressure systems and integrated units.

- Connectivity: 5G integration and Edge computing.

- Advanced Materials: Smart self-healing seals and composite components.

Conclusion

Hydraulic stations remain essential to modern industry, and far from being outdated technology, they are evolving rapidly to meet 21st-century demands. The integration of electro-hydraulic servo control, IoT monitoring, variable frequency drives, and other smart technologies is creating a new generation of hydraulic systems that combine traditional power advantages with modern efficiency and intelligence.

Whether you're operating a small portable unit for field service or managing a facility with dozens of large stationary hydraulic stations, understanding both fundamental principles and cutting-edge innovations is essential for maximizing performance, efficiency, and reliability.

Key Takeaways for 2025

- Electro-hydraulic servo systems deliver unprecedented precision

- IoT monitoring enables predictive maintenance and reduces downtime

- VFD technology dramatically reduces energy consumption

- Hybrid systems combine hydraulic power with electric efficiency

- Sustainability and energy efficiency are now core design priorities

Further Resources

Industry Organizations:

- National Fluid Power Association (NFPA)

- International Fluid Power Society (IFPS)

- European Fluid Power Committee (CETOP)

Technical Standards:

- ISO 4413 (Hydraulic fluid power systems)

- ISO 11171 (Calibration of contamination sensors)

- IEC 61131 (Programmable controller standards)

Publications: