When you're working with hydraulic systems or water pipelines, choosing the right check valve can make the difference between smooth operations and costly repairs. The galvanized check valve Type S has become a popular choice for many industrial applications, but understanding what makes it different from other options isn't always straightforward.

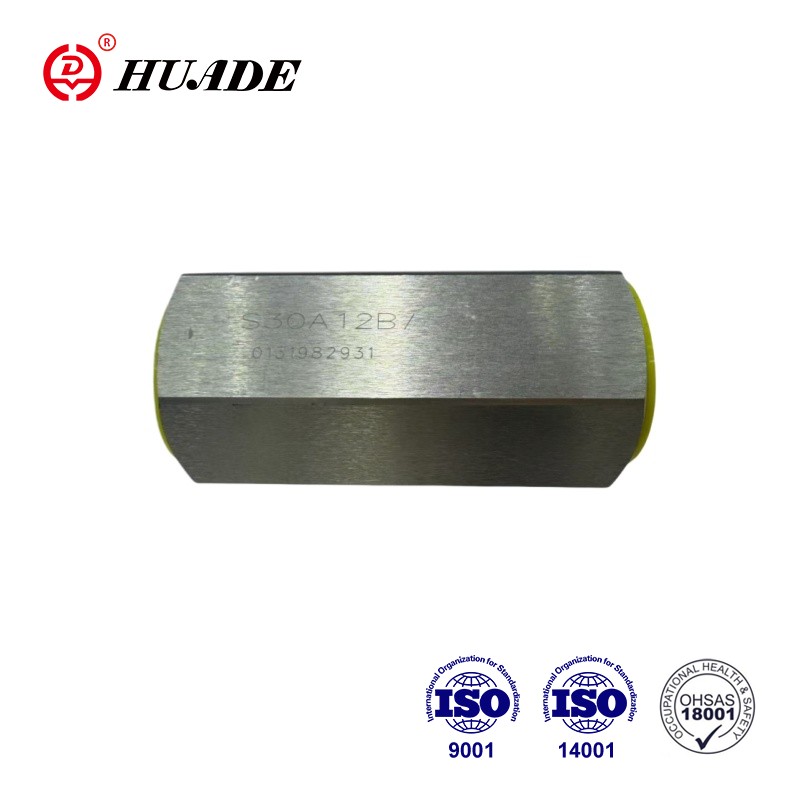

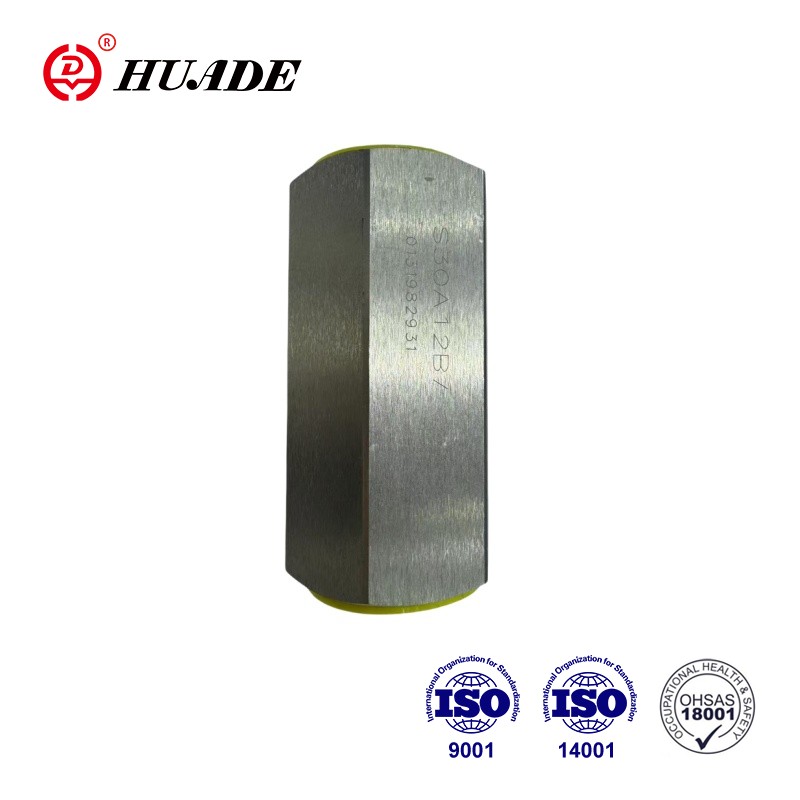

What Is a Galvanized Check Valve Type S?

A galvanized check valve Type S is a one-way flow control device that prevents fluid from flowing backward in your piping system. The "galvanized" part means the valve body has a protective zinc coating applied through either hot-dip galvanizing or electroplating. This zinc layer acts as a shield against rust and corrosion, which is why you'll often see these valves in outdoor installations and water systems.

The "Type S" designation can mean different things depending on whether you're looking at hydraulic equipment or standard plumbing. In hydraulic applications, Type S typically refers to a spring-loaded poppet or plunger design that can handle pressures up to 450 bar (about 6,500 psi). For pipeline work, the S might indicate a swing check valve with socket weld connections or a specific manufacturer's series. This distinction matters because the two designs work quite differently.

How Does the Type S Mechanism Work?

The hydraulic version of a galvanized check valve Type S uses a spring-loaded plunger that slides along a center line. When fluid pressure pushes against the plunger hard enough, it compresses the spring and opens the valve. The moment the pressure drops or tries to reverse, the spring snaps the plunger back into its seat, creating a tight seal. This happens fast, which helps prevent water hammer (those loud banging sounds you sometimes hear in pipes).

The pipeline Type S, on the other hand, usually has a disc or flap that swings on a hinge. Gravity and forward flow push the disc open, and when flow stops, the disc falls back into place. This design handles larger pipe sizes well and doesn't mind solid particles in the water, but it closes more slowly than the plunger type. The choice between these two affects how your galvanized check valve Type S performs in real-world conditions.

Understanding the Galvanized Coating

The galvanizing process involves dipping steel parts into molten zinc at around 840°F. This creates multiple layers: an inner zinc-iron alloy layer that bonds tightly to the steel, and an outer pure zinc layer that takes the hit from environmental exposure. When this outer layer corrodes, it actually protects the steel underneath through a process called sacrificial protection.

Hot-dip galvanizing typically produces a coating thickness of 45 to 85 microns, which can last over 50 years in normal atmospheric conditions. The galvanized check valve Type S benefits from this long-lasting protection, especially when installed outdoors or in unheated buildings. However, the zinc coating does have temperature limits. Continuous exposure above 200°C (392°F) will damage the coating, and above 250°C, the zinc starts to peel away from the steel. This means your galvanized check valve Type S works best in systems handling cool to warm fluids, not steam or high-temperature hydraulic oil.

Pressure and Flow Specifications

A typical hydraulic galvanized check valve Type S can handle working pressures from 35 to 40 MPa depending on the port size. Smaller sizes (6mm to 15mm) usually rate for 40 MPa, while larger sizes (20mm to 30mm) might be limited to 35 MPa. The maximum flow rates range from 15 to 300 liters per minute, which covers most mobile hydraulic equipment and industrial machinery.

The cracking pressure (the minimum pressure needed to open the valve) is another important number. For most Type S designs, this ranges from 0 to 0.6 MPa. A lower cracking pressure means the valve opens more easily, which reduces energy loss in your system. However, too low a setting can cause the valve to flutter when flow fluctuates. Your galvanized check valve Type S should match your system's minimum operating pressure to avoid this problem.

Flow resistance in the Type S design is higher than a swing check valve because the fluid has to push the plunger straight up against spring tension. This creates a pressure drop similar to what you'd see in a globe valve. For high-flow applications where pressure drop matters a lot, you might want to calculate whether a Type S is the right choice or if a swing check would work better.

Temperature Considerations for Galvanized Valves

The temperature range for a galvanized check valve Type S typically runs from -20°C to 80°C for the fluid inside. The ambient temperature should stay between -20°C and 50°C. These limits come from both the zinc coating and the seal materials used inside the valve.

When temperatures climb above 200°C continuously, the zinc coating begins to break down. Short exposures up to 350°C might not cause immediate failure, but repeated cycling at high temperatures will definitely shorten the valve's life. If your system runs hot water above 180°F regularly, you should probably look at stainless steel options instead of a galvanized check valve Type S.

Cold temperatures are generally less problematic for the galvanized coating itself, but you need to watch out for ice formation in water systems. The valve body can crack if water inside freezes and expands. Proper winterization or using glycol mixtures helps prevent this issue in seasonal systems.

Where Galvanized Check Valve Type S Works Best

Fire protection systems are a major application for galvanized check valves. The UL and FM certifications required for fire service check valves often specify galvanized cast iron or ductile iron construction. A Type S design in these systems prevents backflow from fire sprinkler risers and ensures water is always available when needed. The galvanized coating provides decades of protection even in damp valve rooms or outdoor installations.

Irrigation systems also benefit from galvanized check valve Type S installations. Agricultural pumping stations, golf course water systems, and municipal irrigation networks all use check valves to maintain prime in pump lines and prevent reverse flow. The zinc coating handles exposure to fertilizers and minerals in irrigation water better than bare steel, though not as well as stainless steel would.

Mobile hydraulic equipment like excavators, cranes, and agricultural machinery commonly use the high-pressure hydraulic version of a galvanized check valve Type S. These valves protect hydraulic pumps and motors from pressure spikes when the machine shuts down or when loads shift suddenly. The compact design fits into tight spaces, and the galvanized finish resists rust from exposure to rain and mud on job sites.

Municipal water distribution systems sometimes use larger galvanized swing check valves (which might be called Type S by certain manufacturers) at pump stations and pressure zone boundaries. These installations prevent water from flowing backward through pumps when they shut off, protecting the equipment and maintaining proper pressure zones in the distribution network.

Installation Best Practices

Installing a galvanized check valve Type S correctly starts with confirming the flow direction. Every check valve has an arrow molded or stamped on the body showing which way fluid should flow. Installing it backward means the valve stays closed all the time, blocking your system completely.

The valve can be installed in any orientation (horizontal, vertical, or angled), but vertical installation with upward flow is often preferred for the Type S design because gravity helps the plunger seat properly when closing. In horizontal runs, make sure there's adequate support on both sides of the valve to prevent pipe stress from transferring to the valve body.

Thread connections need proper sealant, but avoid getting tape or compound inside the valve where it could interfere with the moving parts. For threaded galvanized check valve Type S installations, use PTFE tape or a pipe dope compatible with your fluid. Don't overtighten threaded connections because this can crack the valve body, especially with cast iron construction.

Flanged connections require even bolt torque following a star pattern to ensure the gasket seats properly. The galvanized finish on flange faces should be smooth enough for gasket sealing, but rough galvanizing might need light sanding before assembly. Check your gasket material compatibility with both the fluid and the operating temperature of your galvanized check valve Type S.

Maintenance Requirements

Regular inspection keeps your galvanized check valve Type S working reliably. For the first six months after installation, monthly checks help catch any installation issues early. After that, quarterly inspections are usually sufficient for most applications. During inspections, look for signs of leaking around the valve body, unusual noises during operation, or changes in system pressure that might indicate valve problems.

The internal parts of a galvanized check valve Type S can get fouled with debris from the piping system. Installing a strainer or filter upstream (15-micron filtration is recommended for hydraulic applications) prevents solid particles from jamming the plunger or collecting under the valve seat. This simple addition can extend valve life significantly and reduce maintenance needs.

If you notice water hammer or loud closing sounds, the valve might be oversized for your flow rate or the cracking pressure might be set too low. Adjusting the spring preload (if your valve design allows it) or replacing the valve with a different size can solve these issues. Persistent leaking past the valve seat usually means debris is stuck on the sealing surface or the seat has worn out and needs replacement.

The external galvanized coating requires minimal maintenance, but if you see white rust (wet storage stain) forming on the surface, wipe it off and allow the valve to dry thoroughly. This white corrosion product is zinc oxide, and while it looks bad, it's actually protecting the steel underneath. True corrosion through to the base metal appears as red or brown rust and indicates the zinc coating has failed in that spot.

Comparing Material Options

When you're deciding between a galvanized check valve Type S and other materials, cost and corrosion resistance are the main factors. Galvanized steel sits in the middle ground: it costs about 40% less than stainless steel but provides much better corrosion protection than bare carbon steel or cast iron.

Stainless steel check valves (typically 316 or 304 grade) offer the best corrosion resistance, especially in saltwater or chemical environments. They handle higher temperatures without coating damage and last longer in harsh conditions. However, stainless steel costs 2.5 to 5 times more than a galvanized check valve Type S. For budget-conscious projects in freshwater or mild industrial settings, the galvanized option makes more financial sense.

Bronze check valves work well in residential plumbing and where higher temperatures are needed, but they're limited to lower pressures than a galvanized check valve Type S. The 450 bar capability of the Type S hydraulic design far exceeds what bronze can handle. Bronze also costs more per valve, though not as much as stainless steel.

Bare steel or cast iron check valves cost less upfront but require painting or other protection in corrosive environments. The maintenance costs and shorter service life usually offset any initial savings. A galvanized check valve Type S provides better long-term value in most situations where extreme corrosion resistance isn't required.

Common Problems and Solutions

Chattering or flutter happens when the valve rapidly opens and closes due to pressure fluctuations near the cracking pressure threshold. This problem often occurs when a galvanized check valve Type S is oversized for the actual flow rate. The solution is either installing a smaller valve or increasing the cracking pressure setting if your valve design allows adjustment. In some cases, adding a small orifice or flow restriction downstream can stabilize the flow pattern.

Water hammer manifests as loud banging noises when the valve closes suddenly. The Type S plunger design generally handles this better than swing checks because the spring-loaded closure happens quickly and smoothly. If water hammer still occurs, you might need a different valve with slower closing characteristics or the addition of a water hammer arrestor in the system. Proper pipe support also helps minimize the noise and stress from pressure surges.

Leaking past the valve seat allows reverse flow, which defeats the whole purpose of having a check valve. Small amounts of leakage (under 0.25 cm³/min or about 5 drops per minute) fall within acceptable specifications for most galvanized check valve Type S designs. Excessive leaking usually means debris has lodged in the seat, the sealing surfaces have worn out, or the spring has weakened. Cleaning or replacing internal components fixes most leakage problems.

External leaking around the body or connections indicates gasket failure or cracked housing. Tightening bolts might stop minor weeping, but if the leak persists, you'll need to disassemble the valve, inspect the sealing surfaces, and replace gaskets. Cracks in the valve body require complete valve replacement because the structural integrity is compromised.

Market Options and Suppliers

Several major manufacturers produce galvanized check valve Type S designs for different markets. Bosch Rexroth, Parker Hannifin, and PONAR Wadowice offer precision hydraulic versions with the high-pressure capabilities and compact sizes needed for mobile equipment and industrial machinery. These companies provide detailed technical data and can help with proper valve selection for demanding hydraulic applications.

For water and plumbing applications, companies like Watts (including their Ames brand), Mueller, and various Chinese manufacturers (FCV, Dervos, Neway) produce galvanized check valves that might be designated as Type S or similar series codes. These valves typically meet ANSI/AWWA standards for water service and come with appropriate certifications for fire protection or potable water use when required.

Pricing varies widely based on size, pressure rating, and certifications. Small hydraulic galvanized check valve Type S units (6mm to 15mm ports) might cost under $100, while certified fire service models in 4-inch size run around $800 to $900. Large 12-inch flanged units can exceed $5,000, especially with UL or FM listings. The certification costs and testing requirements add significantly to the price compared to non-certified industrial valves.

When sourcing a galvanized check valve Type S, consider whether you need a distributor with local inventory for quick delivery or if you can order direct from manufacturers for better pricing on larger quantities. Technical support quality matters too, especially for hydraulic applications where proper selection affects system performance and equipment protection.

Making the Right Choice

Choosing a galvanized check valve Type S makes sense when you need good corrosion protection at a reasonable price in systems operating below 200°C with moderate chemical exposure. The high-pressure capability of the hydraulic Type S design suits mobile equipment and industrial machinery where space is tight and pressure spikes are common. For water systems, the galvanized coating provides decades of service in applications from irrigation to fire protection.

However, a galvanized check valve Type S isn't always the best option. High-temperature systems above 180°F continuous operation should use stainless steel. Saltwater or highly corrosive chemical applications also benefit from upgrading to stainless steel despite the higher cost. Very large pipe sizes (over 12 inches) might work better with epoxy-coated or stainless steel swing checks rather than galvanized Type S designs.

The key factors in your decision should be operating pressure, temperature range, fluid compatibility, and environmental exposure. Match the valve's specifications to your actual system requirements rather than over-specifying for conditions that won't occur. A properly selected galvanized check valve Type S will provide years of reliable service with minimal maintenance, protecting your pumps and equipment while keeping your project within budget.

Understanding what Type S means in your specific context (hydraulic plunger vs. pipeline swing check) helps ensure you get the right valve for your application. When in doubt, consult with the manufacturer or a qualified distributor who can review your system parameters and recommend the appropriate valve configuration. Taking time to make the right choice now prevents expensive mistakes and downtime later.