Let's explore everything you need to know about piston pumps in simple terms.

What is a Piston Pump?

A piston pump is a machine that moves liquids from one place to another. Think of it like a bicycle pump, but instead of pushing air, it pushes water, oil, or other fluids.

These pumps work by using a piston (a moving part) inside a cylinder. When the piston moves up and down, it creates pressure that pushes the liquid where you want it to go.

Piston pumps are popular because they can:

- Handle thick liquids like honey or paint

- Create very high pressure

- Work with liquids that have small pieces in them

- Give you exact control over how much liquid moves

The Two Main Types of Piston Pumps

1. Lift Pump

A lift pump is the simpler of the two types. It uses air pressure from the atmosphere to help move water up from underground.

How Does a Lift Pump Work?

Here's what happens step by step:

- Up Movement: The piston moves up, creating empty space below it

- Water Enters: Air pressure pushes water through a valve at the bottom

- Down Movement: The piston moves down, and water flows through a valve in the piston

- Water Exits: On the next up movement, water gets pushed out through the top

Lift Pump Features:

- Can only lift water about 33 feet (10 meters) high

- Works best for shallow wells

- Simple design that's easy to fix

- Usually operated by hand or simple motors

Where Do We Use Lift Pumps?

- Hand-operated water pumps in rural areas

- Shallow water wells

- Simple water systems in homes

- Emergency water supplies

Pros and Cons of Lift Pumps:

Good Points:

- Cheap to buy and maintain

- Easy to understand and fix

- Works without electricity (hand pumps)

- Reliable for basic water needs

Bad Points:

- Limited to shallow depths

- Can't create high pressure

- May stop working if air gets in the system

- Not suitable for heavy-duty jobs

2. Force Pump

A force pump is more powerful and can push liquids to much higher pressures and distances.

How Does a Force Pump Work?

Here's the process:

- Up Movement: The piston moves up, creating suction that pulls liquid through an inlet valve

- Down Movement: The inlet valve closes, and the piston pushes liquid out through an outlet valve with force

Force Pump Features:

- Can create very high pressure (thousands of times more than lift pumps)

- Works with motors for automatic operation

- Can push liquids long distances

- More complex design with multiple parts

Where Do We Use Force Pumps?

- Car hydraulic systems (brakes, steering)

- Pressure washers for cleaning

- Chemical plants for moving dangerous liquids

- Fire trucks for fighting fires

- Industrial machines

- Oil and gas operations

Pros and Cons of Force Pumps:

Good Points:

- Creates very high pressure

- Can pump liquids long distances

- Works with many different types of liquids

- Very precise control

- Can handle thick, sticky liquids

Bad Points:

- More expensive to buy and maintain

- More complex parts that can break

- May create uneven flow (pulsing)

- Needs more power to operate

Quick Comparison: Lift Pump vs Force Pump

| Feature | Lift Pump | Force Pump |

|---|---|---|

| How it works | Uses air pressure to suck water up | Actively pushes liquid with force |

| Maximum height | About 33 feet (10 meters) | Hundreds or thousands of feet |

| Pressure created | Low pressure | Very high pressure |

| Cost | Cheaper | More expensive |

| Maintenance | Simple and easy | More complex |

| Best uses | Water wells, simple jobs | Industrial work, high-pressure jobs |

Other Ways to Group Piston Pumps

While lift and force pumps are the two main types, engineers also group piston pumps in other ways:

By Piston Arrangement

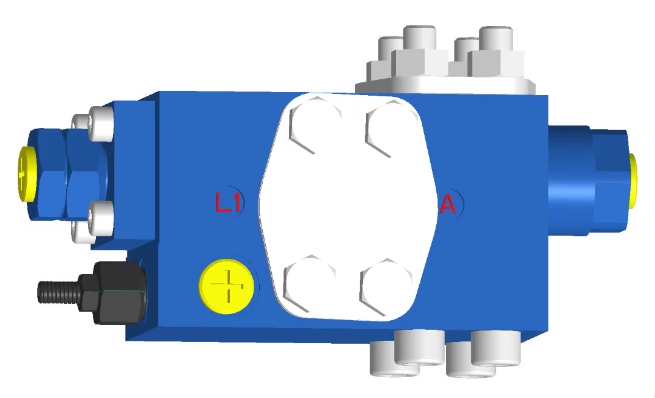

Axial Piston Pumps: The pistons line up like soldiers in a row. These are compact and work well in cars and airplanes.

Radial Piston Pumps: The pistons spread out like spokes on a bicycle wheel. These are very strong and last a long time.

[Compare axial vs radial piston pumps]

By Working Style

Single-Acting Pumps: Only pump liquid in one direction of piston movement. Like breathing in but not breathing out.

Double-Acting Pumps: Pump liquid in both directions of piston movement. Like breathing in and breathing out - more efficient.

By Number of Cylinders

Single Cylinder: One piston doing all the work. Simple but creates uneven flow.

Multiple Cylinders: Several pistons working together. Creates smoother flow and moves more liquid.

What Makes Piston Pumps Special?

Piston pumps have some unique advantages:

High Pressure Power

They can create much higher pressure than other types of pumps. This makes them perfect for jobs that need a lot of force, like hydraulic car lifts or industrial cleaning.

Handle Tough Liquids

Piston pumps can move liquids that other pumps can't handle, such as:

- Thick paint or glue

- Liquids with small pieces in them

- Very hot or very cold liquids

- Dangerous chemicals

Precise Control

You can control exactly how much liquid moves and when. This is important in factories where exact amounts matter.

Keep Working Under Pressure

Even when there's a lot of resistance, piston pumps keep pushing liquid through the system.

Challenges with Piston Pumps

Like all machines, piston pumps have some downsides:

Cost

They cost more to buy and maintain than simpler pumps. The complex parts need regular attention.

Size and Weight

Piston pumps are usually bigger and heavier than other pump types because they need strong parts to handle high pressure.

Uneven Flow

The liquid doesn't flow smoothly - it pulses with each piston stroke. Sometimes engineers add special tanks to smooth out this pulsing.

Lower Volume

Compared to some other pump types, piston pumps move smaller amounts of liquid at one time.

Choosing the Right Materials

The materials used to build piston pumps are very important. Different liquids need different materials:

- Stainless Steel: Great for liquids that cause rust or corrosion. Used in food and chemical industries.

- Ceramic: Very hard material that resists wear from rough liquids with particles.

- Plastic (Polypropylene): Cheap and works well with many chemicals, but not as strong as metal.

- Bronze: Resists saltwater corrosion, good for marine applications.

- Special Alloys: For extremely harsh conditions with dangerous chemicals.

Industries That Use Piston Pumps

Piston pumps work in many different industries:

Agriculture

Farmers use them to spray fertilizers and pesticides with exact amounts on crops.

Construction

Construction workers use high-pressure pumps for cleaning concrete and moving thick materials like paint.

Manufacturing

Factories use piston pumps to move precise amounts of glue, paint, or other materials in production.

Transportation

Cars, trucks, and airplanes use hydraulic piston pumps for brakes, steering, and other control systems.

Energy Production

Power plants use piston pumps to move water and other fluids in their systems.

Mining

Mining companies use strong piston pumps to move muddy water and other tough materials.

The Future of Piston Pumps

Modern piston pumps are getting better all the time. New designs include:

- Computer controls for exact operation

- Better materials that last longer

- Designs that create less pulsing

- More energy-efficient motors

- Self-monitoring systems that warn when maintenance is needed

Making Your Choice: Lift Pump or Force Pump?

When deciding between a lift pump and force pump, consider these questions:

Choose a Lift Pump if:

- You need to pump water from a shallow well (less than 30 feet deep)

- You want a simple, low-cost solution

- You don't need high pressure

- You prefer easy maintenance

Choose a Force Pump if:

- You need high pressure

- You're pumping liquids long distances

- You're working with thick or difficult liquids

- You need precise control

- You're doing industrial or commercial work

Conclusion

Understanding the two types of piston pumps - lift pumps and force pumps - helps you choose the right tool for your job. Lift pumps are simple and perfect for basic water pumping from shallow sources. Force pumps are powerful workhorses that handle demanding industrial applications.

Both types have their place in our modern world. From the simple hand pump bringing water to a rural home to the high-tech hydraulic systems in spacecraft, piston pumps keep our world moving.

Whether you're a homeowner looking to install a well pump, an engineer designing industrial systems, or just curious about how these machines work, knowing the basics of piston pumps helps you make better decisions and understand the technology around us.