The Bosch Rexroth 4WE 6 D directional control valve represents a fundamental component in modern hydraulic systems. This valve operates as an electrically controlled direction switcher that tells hydraulic fluid where to go and when to move. As a standard NG6 size valve, it fits into systems around the world thanks to international standards that make different brands work together. Engineers who need to compare suppliers, check prices, or understand technical details will find this valve offers both reliability and flexibility for medium to high-pressure applications.

Understanding the Basic Function and Design

The 4WE 6 D valve controls hydraulic fluid by switching it between four main ports labeled P, A, B, and T. Port P connects to the pump, ports A and B connect to actuators like cylinders, and port T returns fluid to the tank. The valve works like an electrical switch but for hydraulic oil instead of electricity. When you turn it on, fluid flows one direction. When you turn it off, the flow either stops or reverses depending on the valve design.

Inside the valve sits a metal spool that slides back and forth inside a precisely machined bore. An electromagnet called a solenoid pushes this spool when electricity flows through its coil. The 4WE 6 D uses what engineers call a "wet armature" design, which means the solenoid plunger sits directly in the hydraulic oil. This might sound strange, but it actually makes the valve last longer because there are no rubber seals that wear out around the moving parts. The oil also helps cool the solenoid and reduces noise during operation.

When the solenoid turns off, a return spring pushes the spool back to its starting position. This spring-return design provides a safety feature because the valve automatically returns to a known position if electrical power fails. The force from the spring must overcome both the friction of the moving parts and any pressure in the return line, which becomes important later when we discuss system design limits.

The valve body follows international mounting standards including ISO 4401-03, CETOP 3, and DIN 24340 Form A. These standards define the exact location of mounting holes and port connections. This standardization means the Rexroth 4WE 6 D can physically replace similar valves from Parker, Eaton, or other manufacturers without redesigning the mounting plate. For purchasing managers, this interchangeability creates supply chain flexibility since multiple vendors can provide compatible parts during shortages or price negotiations.

Pressure Ratings and Flow Capacity

The Rexroth 4WE 6 D directional control valve handles serious working pressures. The main ports P, A, and B can operate at pressures up to 350 bar, though most technical documents list the standard maximum at 315 bar. To put this in perspective, 315 bar equals about 4,570 pounds per square inch, which is roughly equivalent to the weight of a small car pressing on an area the size of a postage stamp.

Flow capacity depends on whether you choose a DC or AC solenoid. DC versions can handle up to 80 liters per minute, while AC versions typically max out at 60 liters per minute. The difference comes from the electromagnet design and how quickly it can move the spool. For reference, 80 liters per minute could fill a bathtub in about two minutes.

However, there is one critical pressure limit that catches many designers by surprise. The T port, which returns oil to the tank, cannot exceed 160 bar of pressure. This limitation exists because the return spring and solenoid force must reliably overcome the pressure pushing back from the return line. If return line pressure goes too high, the spool can vibrate, fail to shift properly, or even move when it should stay still. Systems that share return manifolds between multiple valves or use long return lines with restrictions need careful calculation to ensure T port pressure stays within limits.

The relationship between pressure drop and flow follows a predictable pattern. At maximum flow of 80 liters per minute, the valve typically creates about 2.5 bar of pressure loss. This energy converts to heat, which the hydraulic oil must carry away. Operating consistently above rated flow or pressure requires additional cooling capacity and may need special throttle components to maintain acceptable valve response.

Engineers selecting the 4WE 6 D for new designs should verify that system return line pressure stays well below the 160 bar limit with adequate safety margin. A good rule of thumb leaves at least 20-30 bar of cushion to handle pressure spikes during rapid valve switching or when multiple valves switch simultaneously.

Spool Configurations and Operational Variants

The letter and number symbols stamped on valve nameplates describe exactly how fluid flows through different positions. The "D" in 4WE 6 D indicates a specific spool design, typically a spring-centered four-way configuration. In the center position, this spool blocks both P to T and A to B. When energized, it connects P to A and B to T, which would extend a cylinder. When de-energized, the spring returns the spool to center, and the cylinder stops.

Rexroth offers many different spool symbols beyond just D type. Some connect all ports to tank in center position for free-floating actuators. Others block all ports to hold a load. The choice depends on what you need the machine to do when the valve sits in neutral. A press might need a load-holding center, while a material handling system might benefit from a float center that lets actuators move freely during setup.

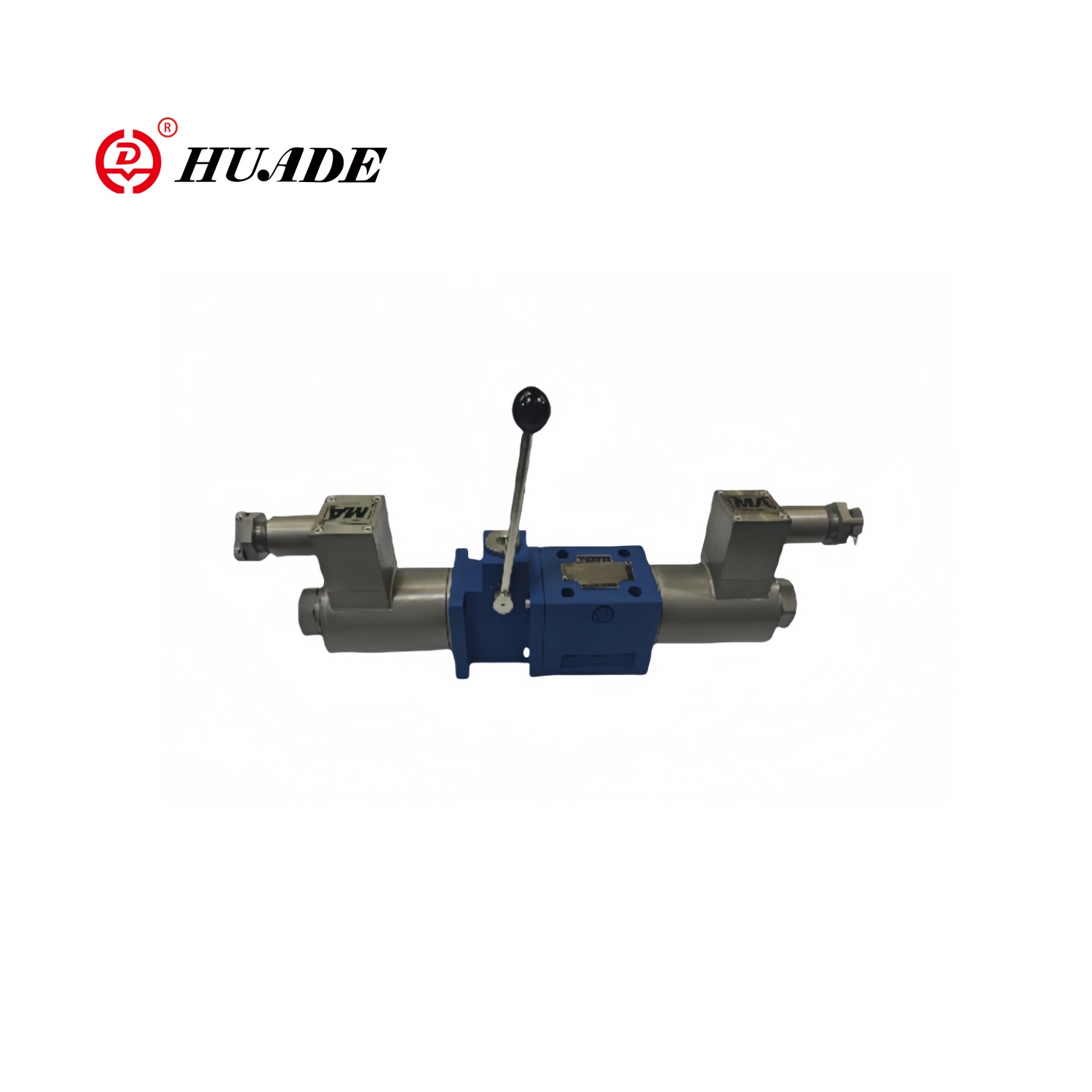

The valve body includes a manual override mechanism usually marked with a small button or knob. During startup or emergencies, technicians can push this override to mechanically shift the spool without electrical power. This feature proves essential when commissioning new systems or troubleshooting problems, since you can verify mechanical function independently from electrical controls.

Some 4WE 6 D models include an "OF" suffix indicating a detent design. These versions have no return spring but instead use mechanical balls or pins that lock the spool in whichever position it was last commanded. A brief electrical pulse shifts the spool, then the detent holds it there without continuous power. This design saves energy and reduces heat but requires extra attention to return line pressure stability since there is no spring force helping to hold the spool in position.

For applications where rapid valve shifting creates pressure shocks, soft-switching variants use precisely shaped grooves and orifices machined into the spool. These features gradually open and close flow paths rather than snapping instantly between positions. The result reduces water hammer effects that can damage pipes and fittings over time. Standard response time runs 10 to 20 milliseconds depending on solenoid type and system pressure.

Electrical Specifications and Environmental Limits

The solenoid coils on the 4WE 6 D directional control valve are built for continuous duty, meaning they can stay energized indefinitely without overheating. At rated voltage, coil temperature rise stays below 30 degrees Kelvin, and expected life exceeds 10 million switching cycles. This durability makes the valve suitable for high-cycle automation where valves might switch several times per second for extended periods.

Available voltages include both DC options at 12, 24, 96, and 205 volts, plus AC options at 110 and 230 volts. The coils tolerate voltage variations of plus or minus 10 percent from nominal, which helps the valve work reliably even when power supplies fluctuate. Electrical connection follows EN 175301-803 standard for three-pole connectors. When properly mated, connectors achieve IP65 protection rating, meaning they resist dust and water jets from any direction.

One practical feature that maintenance technicians appreciate is the removable, rotatable coil. You can unplug the electrical connector, remove the solenoid coil, rotate it 360 degrees to any position that makes wiring easier, and reinstall it without breaking into the hydraulic circuit. This flexibility simplifies installation in tight spaces and allows optimizing wire routing after the valve mounts in the system.

Operating temperature range for standard seals runs from negative 30 to positive 80 degrees Celsius. The hydraulic fluid itself must maintain viscosity between 10 and 500 square millimeters per second, though optimal performance occurs around 25. The valve weighs approximately 1.46 kilograms, light enough for easy handling during installation but heavy enough to feel substantial and well-made.

An important safety consideration involves fluid ignition temperature. The hottest surface on the solenoid can reach 150 degrees Celsius during continuous operation. The hydraulic oil must have an ignition temperature at least 50 degrees higher than this, meaning minimum 200 degrees Celsius ignition point. Most mineral hydraulic oils easily meet this requirement, but synthetic fluids or unusual formulations need verification before use.

Hydraulic Fluid Requirements and System Protection

Long-term reliability of the Rexroth 4WE 6 D directional control valve depends heavily on hydraulic fluid quality. The precise clearances between the sliding spool and valve body bore measure only a few micrometers. Contamination particles larger than these clearances cause rapid wear and eventual failure through two distinct mechanisms.

First, particles get caught between the spool and bore causing what technicians call "stiction." The spool sticks in place and refuses to shift when commanded. This might appear intermittent at first as particles wedge temporarily then work free, but the problem inevitably worsens as more particles accumulate. Second, particles act like grinding paste that gradually wears away the precision surfaces. As clearances open up, internal leakage increases. This leakage not only wastes pump power but generates heat that degrades the oil and accelerates seal wear throughout the system.

Rexroth specifies maximum contamination level as ISO 4406 Class 20/18/15. This classification means no more than 5,000 particles larger than 4 microns per milliliter of oil, no more than 1,300 particles larger than 6 microns, and no more than 320 particles larger than 14 microns. Achieving this cleanliness requires effective filtration with a beta ratio of at least 75 at 25 microns.

In practical terms, the filtration system often costs more over the valve's lifetime than the valve itself. Filter elements need regular replacement, and oil analysis testing confirms contamination stays within limits. Penny-pinching on filtration leads to expensive valve replacements and unexpected downtime. Engineers designing new systems should budget for high-quality filters and plan for filter maintenance as a critical rather than optional task.

The standard fluid is mineral hydraulic oil meeting DIN 51524 parts 1, 2, and 3. The valve also works with certain synthetic fluids and water-glycol mixes if you specify appropriate seal materials. Standard nitrile rubber seals work fine with petroleum oils, but high-temperature applications need fluoroelastomer seals, and water-based fluids require special compounds marked MH or MT.

Role as Pilot Valve and Leakage Characteristics

The 4WE 6 D valve frequently serves as a pilot stage controlling larger directional valves. In this application, the small 4WE 6 D switches pilot pressure that moves a much larger spool in a main stage valve. The main valve might handle 600 liters per minute or more, far beyond the 4WE 6 D's direct capacity, but uses the 4WE 6 D's reliable switching to make control decisions.

When used as a pilot valve, the 4WE 6 D's performance directly affects safety and response of the entire high-flow system. Any instability in the pilot valve T port or excessive internal leakage in the pilot valve creates errors in main stage positioning. This makes fluid cleanliness and T port pressure stability even more critical in pilot valve applications. The small pilot valve essentially becomes the brain that controls a much more powerful body, so keeping that brain healthy requires extra attention.

All spool-type valves have some internal leakage by design. The clearance between spool and bore must allow smooth movement, which means it cannot seal perfectly like a poppet valve. New valves leak very little, typically less than 0.5 liters per minute at full pressure. As the valve accumulates operating hours and wear increases clearances, leakage gradually increases. This is normal and expected.

System designers must account for this internal leakage, especially in applications holding loads. A cylinder using a 4WE 6 D to maintain position will slowly drift as oil leaks internally through the valve. For static holding, adding a pilot-operated check valve or using a load-holding spool design becomes necessary. Monitoring leakage rate over time also provides early warning of wear. When leakage exceeds manufacturer limits, replacing the valve before complete failure prevents unexpected breakdowns.

Comparing Competitive Options and Cross-Reference Strategy

The NG6 standardization means several major manufacturers offer interchangeable alternatives to the Rexroth 4WE 6 D directional control valve. Understanding competitive options helps buyers negotiate better prices and maintain supply chain flexibility.

Parker Hannifin produces the D1VW series, which directly competes with the 4WE 6 D. These valves meet the same NFPA D03 and CETOP 3 mounting standards with similar pressure ratings around 345 bar and flow capacity to 80 liters per minute. Parker emphasizes precision manufacturing and energy efficiency, offering numerous electrical variants including AC rectified coils and soft-switching spool designs.

Eaton Vickers manufactures the DG4V-3 series, known for rugged construction suitable for heavy-duty applications. Cross-reference tables confirm specific Rexroth models like the 4WE 6 D with OF detent have direct Vickers equivalents such as DG4V-3-2N. The Vickers brand carries a strong reputation in high-pressure systems, though prices often run slightly higher than other options.

The critical detail when cross-referencing involves T port pressure ratings. While main working pressure capabilities stay similar across brands, return port limits vary significantly. Standard Rexroth 4WE 6 D allows 160 bar at the T port. Parker D1VW with AC solenoids only permits 103 bar return pressure, but DC or AC rectified versions increase this to 207 bar. If your system design approaches 160 bar return pressure, substituting a standard Parker AC valve would cause failures due to insufficient return pressure capability.

This variation highlights why buyers cannot simply assume mechanical interchangeability equals functional equivalence. Complete specifications including electrical type and all pressure ratings must match before approving a substitute. Purchasing departments should maintain a verified cross-reference list showing not just part numbers but confirming critical parameters match application requirements.

The standardization advantage extends beyond just emergency substitutions. During the design phase, engineers can specify "Rexroth 4WE 6 D or approved equivalent" then maintain relationships with multiple suppliers. This competition keeps pricing reasonable and ensures parts remain available even when one manufacturer faces supply chain delays. The key is doing homework upfront to verify what truly qualifies as an equivalent rather than discovering incompatibility after installation.

Moving Beyond On-Off: When to Consider Proportional Control

The Rexroth 4WE 6 D directional control valve offers only binary operation. It switches fully on or fully off with nothing in between. This works perfectly for many applications like clamping, part ejection, or simple extend-retract cycles. However, modern automation increasingly demands variable speed, smooth acceleration, and precise position control that on-off valves simply cannot provide.

Proportional valves like the Rexroth 4WRPEH series fill this gap by continuously varying flow in proportion to an electrical input signal. Instead of just on or off, the valve can be commanded to 25 percent flow, 63 percent flow, or any other value. This enables controlling cylinder speed throughout its stroke, implementing soft start and stop to reduce shock loads, and achieving smooth motion in multi-axis systems.

The 4WRPEH series maintains the same NG6 size and mounting pattern as the 4WE 6 D, making it a direct mechanical upgrade path. Flow capacity ranges from 4 to 40 liters per minute depending on model. The valve includes onboard electronics that process control signals, provide position feedback, and implement sophisticated control algorithms. This integrated electronic design contrasts sharply with the simple electromagnetic switching of the 4WE 6 D.

Position feedback allows the control system to verify the spool actually moved to the commanded position. This closed-loop control achieves accuracy within fractions of a millimeter, enabling applications like servo presses that need precise force control or machine tools requiring smooth contouring. The electrical feedback signal also enables diagnostic monitoring to detect wear or malfunction before complete failure occurs.

Modern proportional valves include digital communication interfaces like IO-Link that connect them into Industry 4.0 manufacturing environments. The valve becomes a smart sensor providing real-time performance data, maintenance predictions, and configuration parameters. This represents a generational leap from the basic electrical connection of a 4WE 6 D directional control valve.

When should you choose proportional over on-off control? If the application involves any of these requirements, proportional control deserves serious consideration: variable speed operation, smooth acceleration and deceleration, pressure ramping for gentle part contact, position holding without mechanical locks, or integration into programmable motion controllers. On the other hand, if you simply need reliable direction switching and flow volume stays constant during operation, the simpler and less expensive 4WE 6 D remains the better choice.

Many machine builders start with on-off valves then retrofit proportional control later as customer demands evolve. The mechanical compatibility makes this upgrade relatively straightforward, though the electrical integration and system tuning require additional engineering effort. Planning for possible future upgrade by designing with adequate electrical infrastructure and control system capacity saves money compared to complete redesign later.

Purchasing Considerations and Supply Chain Realities

Real-world pricing for the Rexroth 4WE 6 D directional control valve varies considerably based on specific model, supplier, and market conditions. New valves typically range from 350 to 730 US dollars depending on configuration and quantity. Volume discounts apply for orders of ten or more units, with some distributors offering tiered pricing that reduces per-unit cost by 15 to 25 percent at higher quantities.

Online marketplaces like eBay list both new and used valves at various price points. While used valves might seem attractive for cost savings, the history and internal condition remain unknown. Since internal leakage increases with wear and measuring it requires flow testing equipment, used valves carry significant risk unless the seller provides certified test results. For critical applications, the modest savings rarely justify the reliability uncertainty.

Authorized distributors like [BuyRexroth.com](http://buyrexroth.com/) maintain stock of common configurations with typical delivery of 28 business days for standard models. This represents roughly six weeks, which seems long for such a standard component but reflects ongoing global supply chain pressures affecting the entire industrial automation sector. Less common valve configurations or special options like corrosion-resistant coatings can extend lead times to 12 weeks or more.

These lead times create real planning challenges for equipment manufacturers and maintenance departments. Ordering valves after a machine design is finalized risks delaying the entire project if delivery takes longer than expected. Similarly, maintenance operations should stock critical spare parts rather than waiting for emergency orders during breakdowns. The financial carrying cost of inventory needs balancing against the much higher cost of production downtime while waiting for parts.

International shipping adds another layer of complexity. Hydraulic valves qualify as standard industrial goods without special export restrictions, but shipping costs and customs clearance time vary significantly by destination. Ordering from regional distributors rather than shipping directly from Germany often provides faster delivery and simpler logistics despite possibly higher unit prices.

The total cost of ownership extends far beyond purchase price. Installation labor, integration engineering, commissioning time, and ongoing maintenance all contribute to lifetime costs. Most significantly, the filtration system required to maintain proper oil cleanliness often costs more over ten years than multiple valve replacements. Neglecting filtration to save short-term costs leads to premature valve failure, creating much higher long-term expenses.

Buyers focused only on lowest purchase price often create expensive problems later. A complete evaluation considers vendor reliability, technical support quality, spare parts availability, and warranty terms alongside price. Establishing relationships with multiple approved suppliers provides resilience against unexpected supply disruptions while maintaining quality standards.

Maintenance Requirements and Troubleshooting Access

Standard product catalogs for the 4WE 6 D directional control valve provide specifications and dimensions but notably lack detailed maintenance procedures or troubleshooting guides. Manufacturers typically consider this operational knowledge as technical expertise requiring separate service documentation.

Rexroth and HYDAC publish comprehensive service manuals that cover disassembly procedures, wear limit specifications, recommended spare parts, and diagnostic flowcharts. These manuals are not freely available but require purchase or are provided to customers who complete official training courses. This policy protects manufacturer knowledge while ensuring personnel performing maintenance have proper training.

For maintenance teams, this means you cannot rely solely on catalog information to diagnose problems or plan repairs. Establishing contact with the manufacturer's technical support group before issues arise saves time during emergencies. Many distributors offer training programs that cover multiple valve types and provide hands-on experience with disassembly and testing procedures.

Common maintenance tasks include solenoid coil replacement, seal renewal, and spool cleaning. The wet armature design allows replacing coils without opening the hydraulic cavity by rotating the coil 90 degrees and lifting it off. This five-minute procedure requires no fluid drainage or system depressurization. New seals and a cleaned spool can restore like-new performance to valves showing increased internal leakage, provided wear has not opened clearances beyond specification.

Diagnosing valve problems systematically avoids wasted effort replacing parts randomly. If a valve fails to shift, first verify electrical power reaches the coil with proper voltage. Check coil resistance with an ohmmeter to confirm the winding has not burned out. If electrical checks pass, hydraulic problems become suspect. Contaminated oil may have caused spool sticking, requiring disassembly and cleaning. Low supply pressure might provide insufficient pilot pressure to shift the spool against load forces.

Electrical testing requires knowing the coil resistance specification, which appears in detailed data sheets but not basic catalogs. Typical DC coils measure 15 to 40 ohms depending on voltage rating. AC coils show much lower resistance, often 5 to 15 ohms, since they rely on inductance rather than pure resistance for current limiting. An open circuit indicates a burned-out coil, while very low resistance suggests shorted windings.

Real-World Application Guidance

Industrial presses represent a classic application for the 4WE 6 D directional control valve. The valve controls cylinder extension to apply pressing force and retraction to release. A pressure relief valve limits maximum force, while the directional valve simply commands direction. This straightforward control suffices for many pressing operations where force and speed stay constant.

Injection molding machines use multiple directional valves including 4WE 6 D models to control clamp cylinders, ejector pins, and core pulls. These functions require reliable direction control with minimal leakage to avoid part quality issues. The valve's ability to operate at 315 bar accommodates the high clamping forces needed for large molds.

Mobile hydraulic equipment like excavators and cranes employs directional valves throughout the system. The 4WE 6 D often serves as pilot valve feeding pilot pressure to much larger main control valves in the operator's console. This architecture keeps the operator controls light and responsive while main valves handle the heavy flows driving boom, stick, and bucket cylinders. The compact NG6 size fits easily into pilot valve manifolds serving multiple functions.

Assembly line automation frequently uses 4WE 6 D valves for part transfer, clamping, and pressing operations. The fast response time supports cycle rates of several operations per minute. The long life expectancy proves important since valve failure on an automated line stops production affecting multiple downstream stations.

Each of these applications demands attention to specific details beyond basic specifications. Press controls need careful pressure relief valve sizing to protect tooling. Molding machines require addressing the high heat loads from continuous cycling. Mobile equipment faces shock, vibration, and temperature extremes that challenge valve reliability. Automated systems need integration with programmable controllers and safety circuits. The 4WE 6 D provides a capable foundation but succeeds only when the complete system design addresses these application-specific requirements.

Making the Selection Decision

Choosing the Rexroth 4WE 6 D directional control valve starts with verifying it meets fundamental requirements. System pressure must stay at or below 350 bar, flow demand should not exceed 80 liters per minute for DC solenoids or 60 liters per minute for AC versions, and return line pressure must remain under 160 bar including pressure spikes.

Electrical specifications need matching to available power supplies. While 24-volt DC has become nearly universal in modern industrial controls, older equipment might require 110 or 230-volt AC versions. Confirm voltage tolerance stays within the plus or minus 10 percent rating to avoid reliability problems in facilities with marginal power quality.

Environmental conditions determine seal material selection. Standard nitrile rubber works from negative 30 to positive 80 degrees Celsius with petroleum oils. High-temperature applications above 80 degrees need fluoroelastomer seals. Water-based fluids require specific seal compounds that resist the different chemical environment. Similarly, verify the hydraulic fluid meets DIN 51524 standards or consult the manufacturer regarding alternative fluids.

Mounting considerations include both the valve interface and the solenoid orientation. Ensure the mounting surface provides a flat sealing plane with proper bolt torque and O-ring seals. Plan electrical routing to take advantage of the rotatable solenoid, positioning the connector where wiring is convenient and protected from mechanical damage.

The decision between standard spring-return and detent versions depends on duty cycle and energy availability. Detent valves save energy in applications where valve position changes infrequently and must hold for extended periods. Spring-return valves provide clearer failure modes since loss of power returns them to a defined safe state.

For applications requiring variable speed control, smooth acceleration, or position feedback, the 4WE 6 D limitations become apparent. This signals when to consider proportional valves despite higher cost and complexity. The decision often depends on whether the application truly needs modulation or whether on-off control with proper circuit design achieves the required results.

Beyond the valve itself, success depends on proper system design. Size the hydraulic power unit to provide adequate flow at required pressure with reasonable heat generation. Install filtration meeting the ISO 4406 Class 20/18/15 requirement. Design return lines to minimize back pressure at the T port. Include pressure relief protection and proper system flushing during initial startup to remove assembly contamination.

Conclusion and Strategic Recommendations

The Rexroth 4WE 6 D directional control valve remains an industry standard for good reasons. Its high-pressure capability, standardized interfaces, and proven reliability make it a sound choice for medium to high-pressure hydraulic systems requiring dependable direction control. The global acceptance of NG6 mounting standards provides supply chain flexibility through multiple qualified vendors.

However, successful application requires respecting the valve's limits and maintaining the hydraulic environment it needs. The 160-bar T port pressure limit is not a suggestion but a hard boundary that causes failures when exceeded. Engineers must carefully analyze return line dynamics, especially in systems with multiple valves sharing common return manifolds.

Hydraulic fluid cleanliness is equally non-negotiable. Meeting ISO 4406 Class 20/18/15 requires investment in proper filtration and ongoing maintenance. This represents the largest lifetime cost associated with the valve and deserves appropriate budget priority. Saving money on filtration creates much larger costs through premature valve replacement and unexpected downtime.

Taking advantage of standardization means maintaining approved cross-reference lists with verified specifications. The mechanical interchangeability of NG6 valves across brands provides supply chain resilience only when substitutions are technically validated rather than assumed. Pay particular attention to T port pressure ratings when comparing alternatives.

For new machine designs, consider whether on-off control truly meets current and future needs. The 4WE 6 D serves well in applications where direction switching and constant flow suffice. When variable speed, smooth motion, or integrated diagnostics become requirements, proportional valve technology delivers capabilities worth the additional investment.

The valve represents mature technology with a clear understanding of capabilities and limitations. Success comes from respecting those boundaries, maintaining the hydraulic environment properly, and matching valve capabilities to application requirements. Used appropriately, the 4WE 6 D directional control valve provides years of reliable service in demanding industrial applications.